Micro-lens light-absorbing and micro-spherical silicon light-condensing combined solar cell

A silicon solar cell and solar cell technology, applied in the field of solar cells, can solve the problems of solar cell power generation capacity limitation, inability to charge, power generation effect is not as good as monocrystalline silicon, etc., to improve photoelectric conversion efficiency, improve power generation effect, and good power generation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and examples, but the protection scope of the present invention is not limited to the range indicated by the examples.

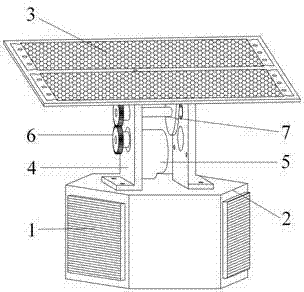

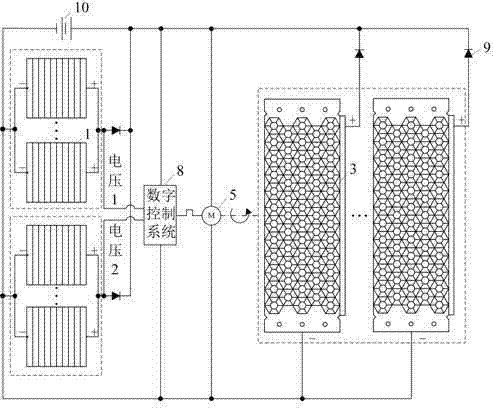

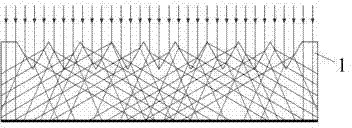

[0026] Such as figure 1 It is a schematic diagram of the overall structure of the present invention, including a hollow base 2 inside, N 1 A microlens structure thin film solar cell 1 is equally divided into two groups and placed vertically on the side of the base 2, the said N 1 ≥2 and is an even number, N 2 A concentrating microsphere silicon solar cell 3 is placed on a support 4, the N 2 ≥1. figure 2 It is the schematic diagram of the self-adaptive tracking sun rotation of the embodiment of the present invention. When the sun appears at a certain position, compare the voltages at both ends of the two sets of microlens structure thin-film solar cells, and trigger the stepper motor 5 to rotat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com