Linear motion device with elastic housing

A technology of linear motion and shell, applied in the direction of linear motion bearings, electromechanical devices, electric components, etc., can solve the problems of unusable guide rails, etc., and achieve the effect of saving materials and improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

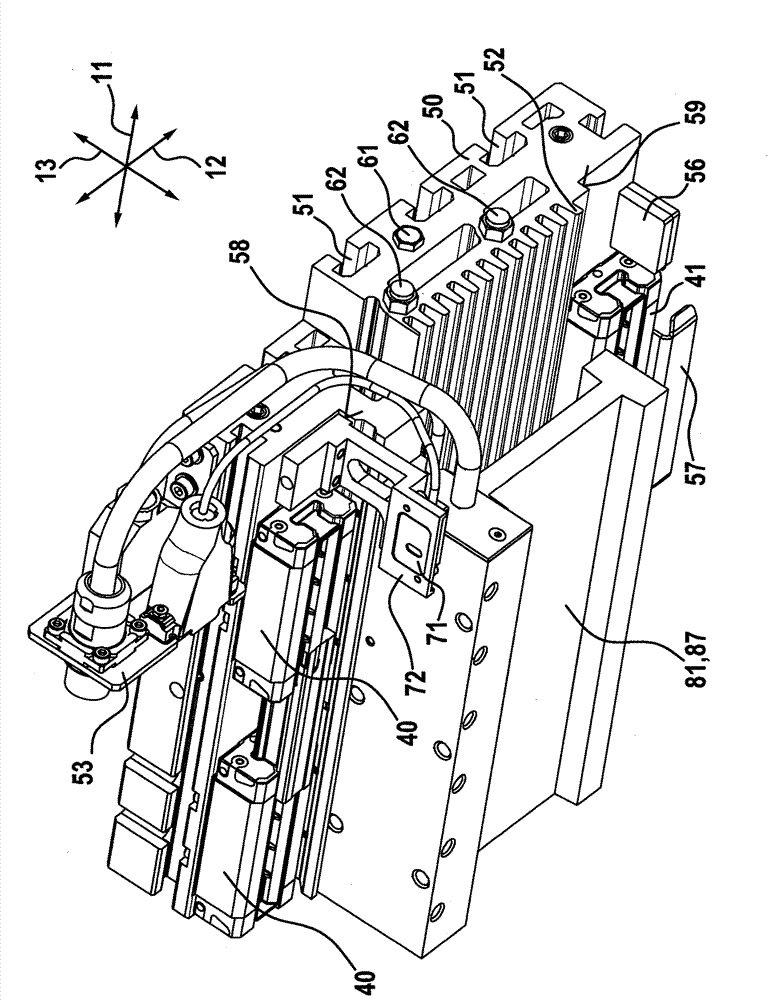

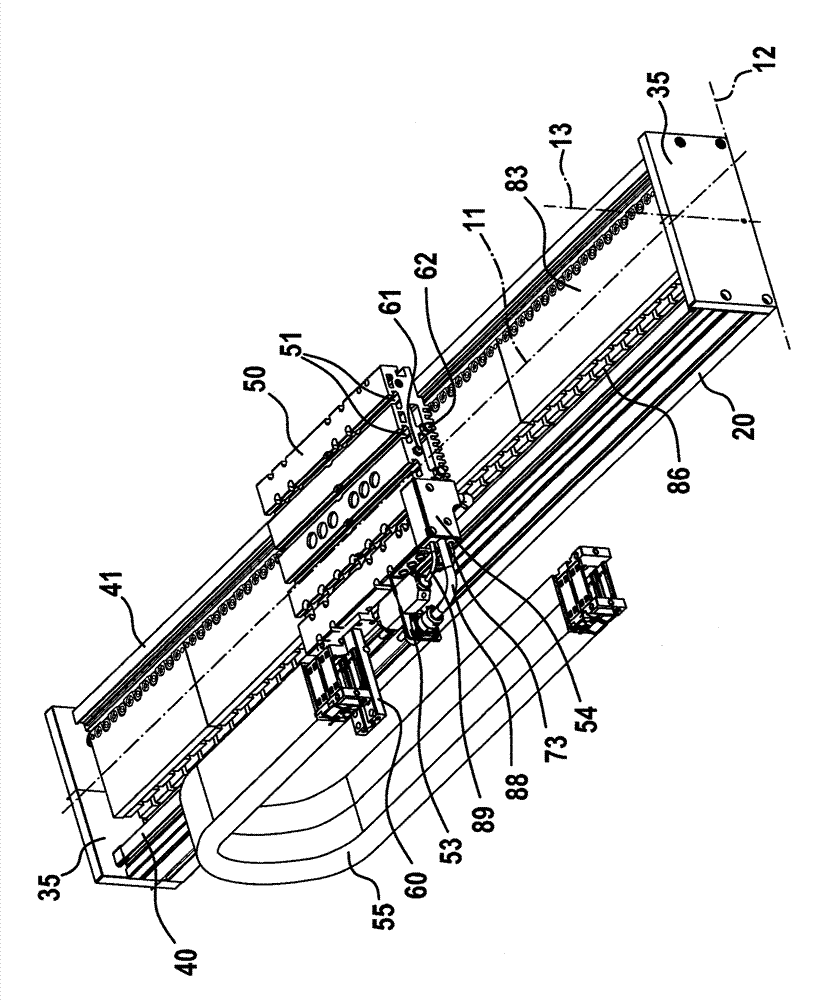

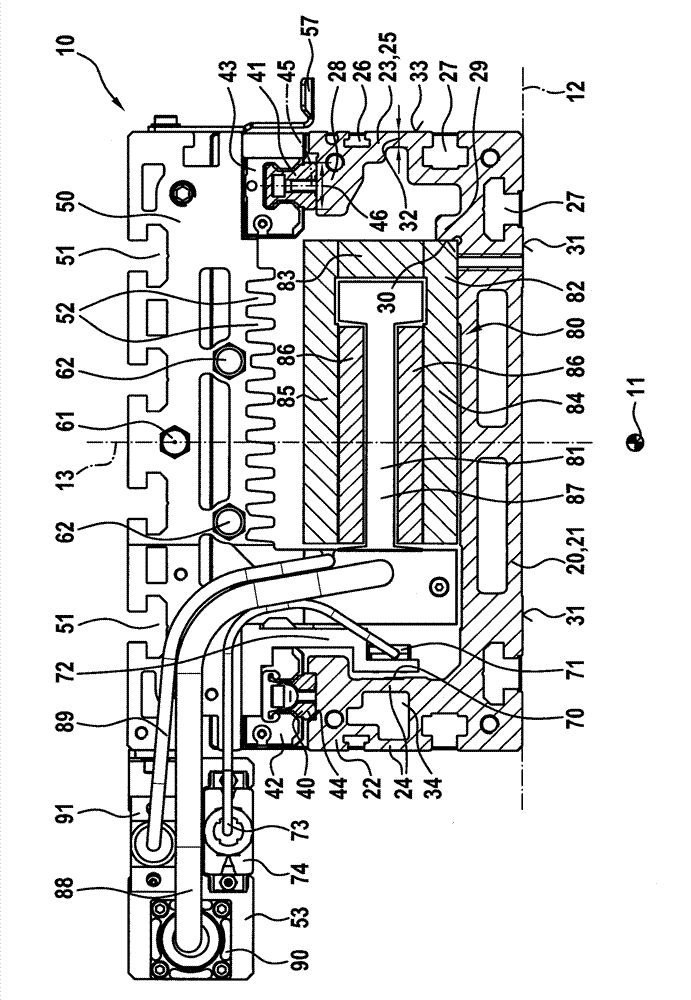

[0090] figure 1 A perspective view of the linear motion device 10 according to the invention is shown. The linear motion device 10 comprises a housing 20 which extends along the longitudinal axis 11 with a constant, U-shaped cross-sectional shape. The housing 20 is made of aluminum and is produced by extrusion. However, it is also conceivable to produce the housing 20 chip-free, in particular by milling. On the two longitudinal ends of the housing 20 , a rectangular end plate is respectively arranged, and the end plates are screwed together with the housing 20 . Furthermore, straight first and second guide rails 40 , 41 are fastened to the housing 20 , said first and second guide rails being parallel to the longitudinal axis over almost the entire length of the housing 20 11 extensions. Two first or two second guide vehicles respectively (in image 3 reference numerals 40 , 41 ) are supported on the first and second guide rails 40 , 41 in a movable manner in the direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com