Device and method for measuring water permeability coefficient of asphalt pavement

A technology for measuring device and water permeability coefficient, which is used in measuring device, permeability/surface area analysis, suspension and porous material analysis, etc. It can solve the problems of gas can not be discharged, sealing can not be guaranteed, test failure, etc., to achieve a simple installation process Reliable, improve the success rate of measurement, the effect of smooth and sufficient exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

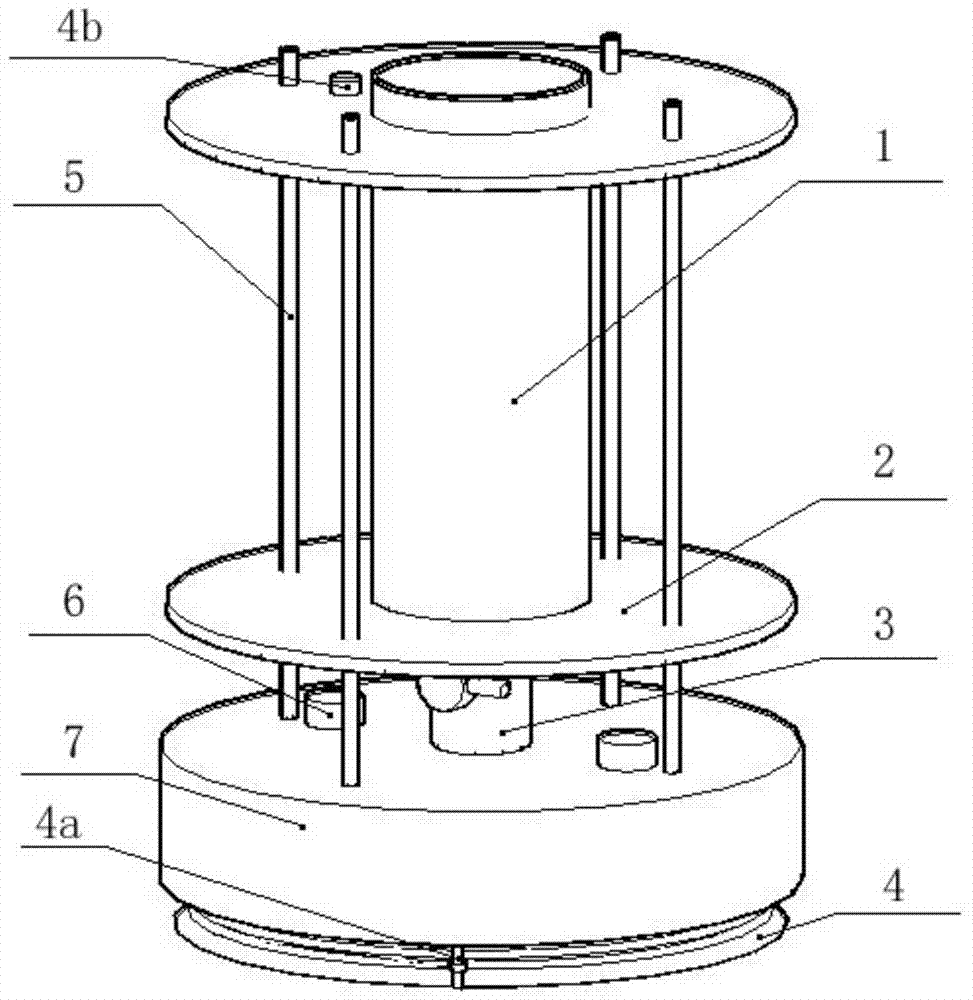

Method used

Image

Examples

Embodiment 1

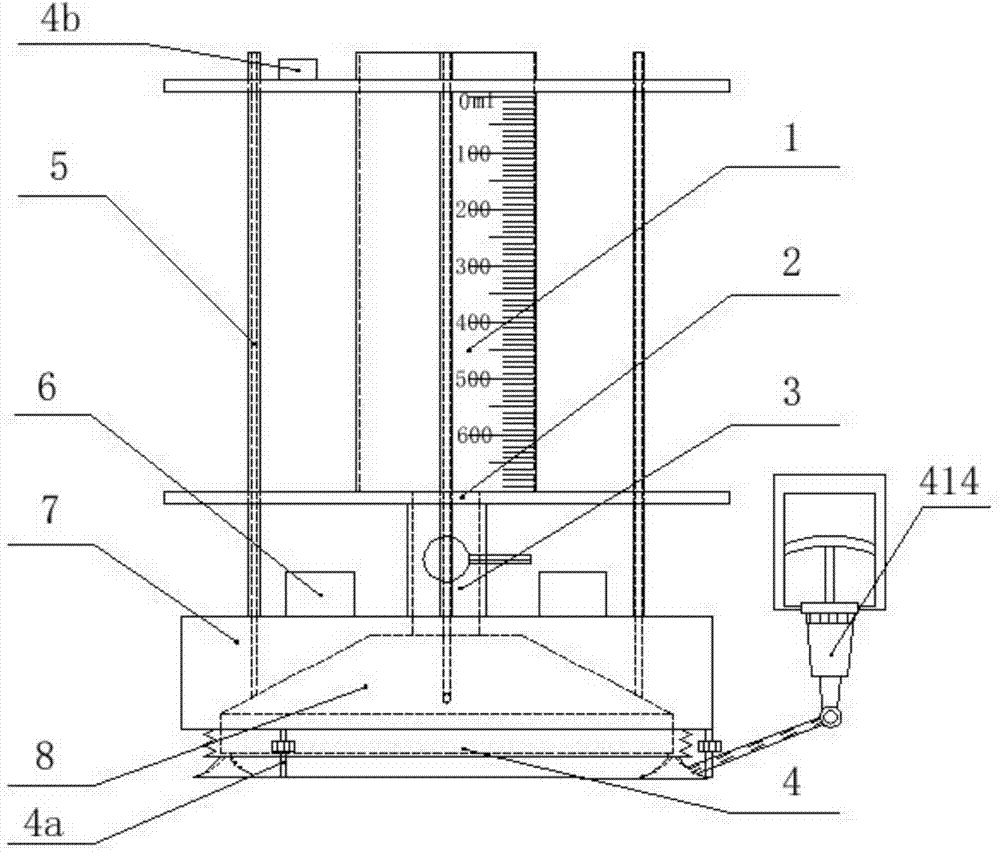

[0052] for image 3 with Figure 4 The structural form of the sealing leveling ring 4 shown, the measuring method of the asphalt pavement water seepage coefficient measuring device is to carry out as follows:

[0053] Step 1. On the test area of the road surface, remove the dust in the road surface and the gaps of the road surface, and place the measuring device;

[0054] Step 2: Use ring-shaped sealing material to seal and smooth the road surface gap in the area corresponding to the rubber suction cup 412, use the rubber suction cup 413 to form a seal between the road surface and the base 7, and adjust the bolt 4a vertically so that the horizontal air bubbler 4b The air bubble is centered; during the adjustment process, first adjust the three vertical height adjustment bolts 4a to the minimum height, align the rubber suction cup 412 with the annular sealing material and press, and then use the air pump 414 to extract the air in the horn chamber 413 to detect After there i...

Embodiment 2

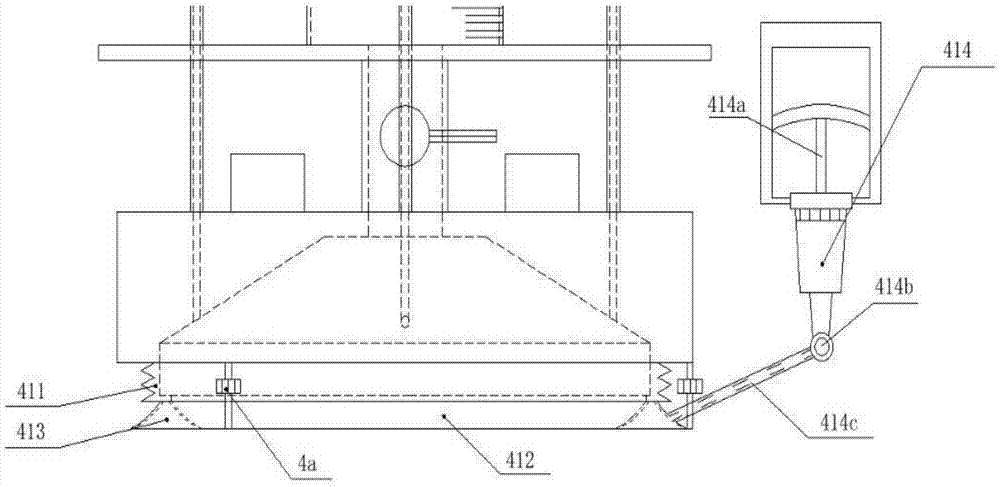

[0062] for Figure 5 with Image 6 The structural form of the sealing leveling ring 4 shown, the measuring method of the asphalt pavement water seepage coefficient measuring device is to carry out as follows:

[0063] Step 1. On the test area of the road surface, remove the dust in the road surface and the gaps of the road surface, and place the measuring device;

[0064] Step 2. Adjust the vertical height adjustment bolt 4a so that the air bubbles in the horizontal bubbler 4b are centered, complete the leveling of the base 7, and use the up and down movable performance of the annular baffle 421 to make the bottom surface of the annular baffle 421 contact the road surface. At the local gap between the bottom surface of the annular baffle plate 421 and the road surface, use a sealing material to fill the gap; then turn on the power switch 424, and the solid wax in the wax tank 422 will melt after being heated and ooze out from the wax tank 422. Sealing is formed between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com