Intelligent primary air pressure target value control system and method

An intelligent control system and target value technology, applied in the direction of combustion control, combustion method, air supply adjustment, etc., can solve the problem of increasing the power consumption of the primary fan, and achieve the effect of offsetting adverse effects, meeting demand, and increasing the amount of pulverized coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described in further detail below in conjunction with accompanying drawing:

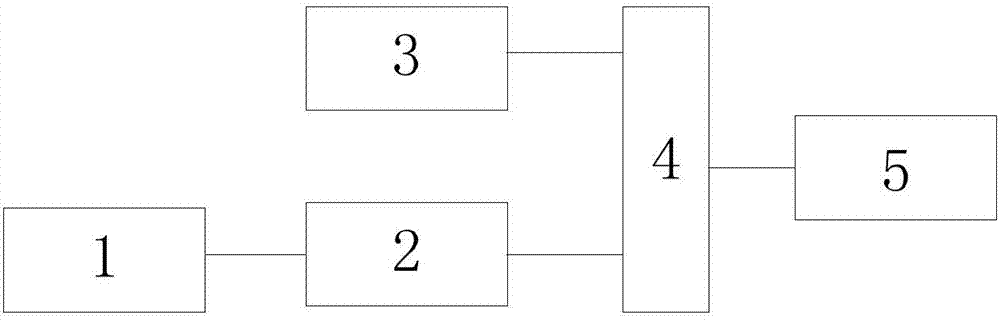

[0013] refer to figure 1 According to this method, the primary air pressure target value intelligent control system of the present invention includes a controller 5, an adder 4, a first control logic module 3 for generating a preset value of a reference primary air pressure, and a first control logic module 3 for generating an additional primary air pressure. The second logic control module 2 of the preset value of the pressure, and the acquisition module 1 for collecting the AGC instruction issued by the power management system; the output terminal of the acquisition module 1 is connected to the input terminal of the second logic control module 2, The output end of the second logic control module 2 is connected with the output end of the first control logic module 3 and the input end of the adder 4, and the output end of the adder 4 is connected with the input end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com