Automatic net paving device of anchor rod drill carriage for coal mine

A technology for bolting rigs and coal mines, applied in the field of parts and components, can solve problems such as low efficiency, and achieve the effect of improving laying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

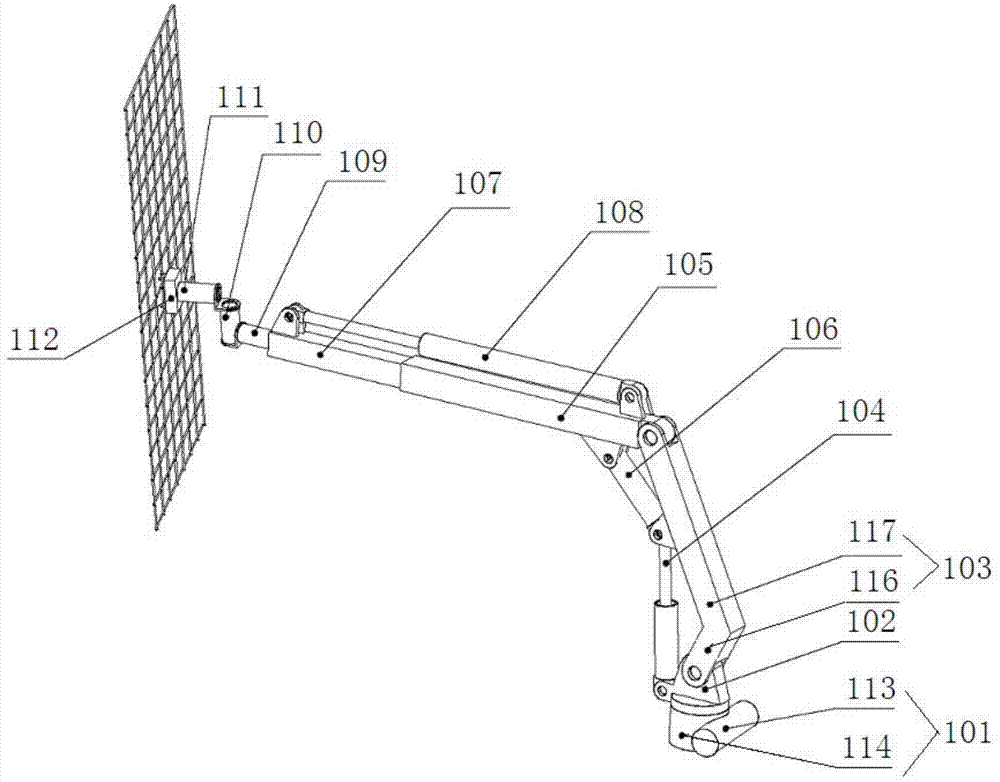

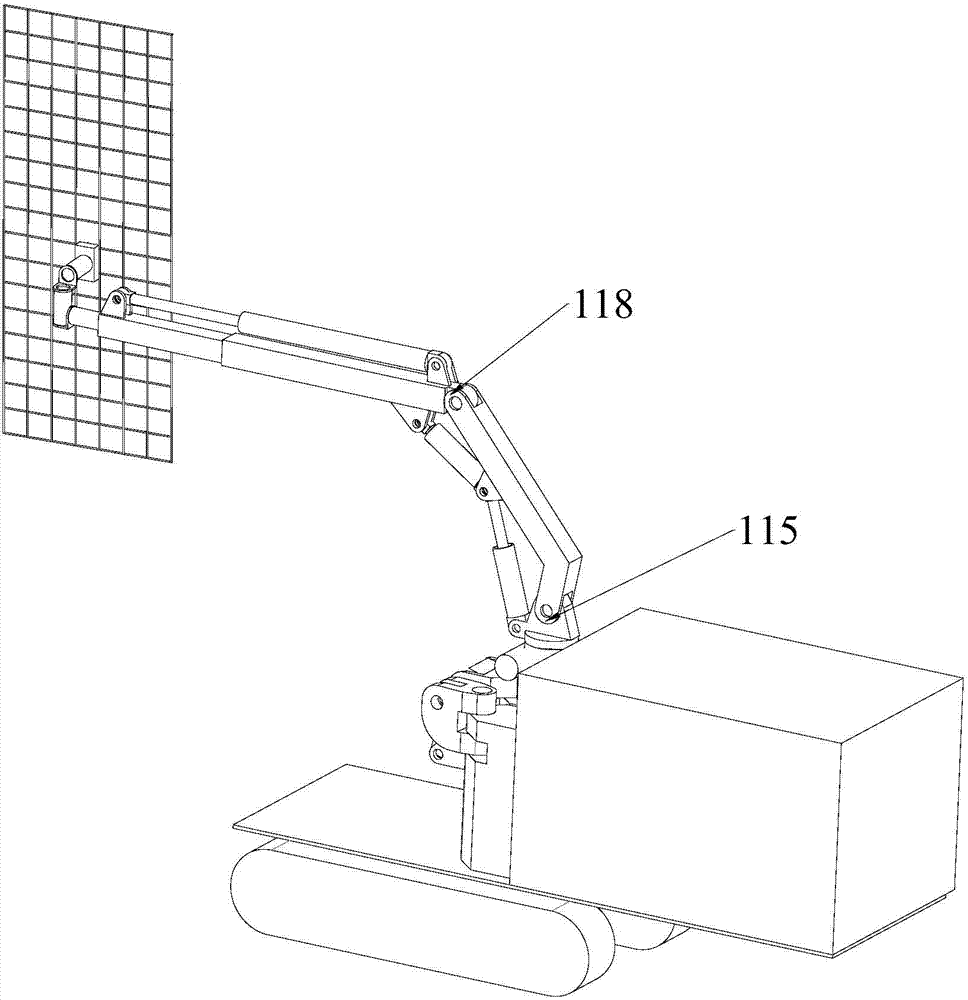

[0026] This embodiment provides an automatic mesh laying device for a coal mine bolt drill carriage, which includes a rotating base 101, an ear seat 102, a first arm 103, a first cylinder 104, a second arm 105, a second cylinder 106, and a second cylinder. The three arms 107, the third oil cylinder 108, the first spiral swing cylinder 109, the second spiral swing cylinder 110, the third spiral swing cylinder 111 and the magnetic manipulator 112.

[0027] The rotating base 101 is installed on the chassis of the coal mine bolt rig when in use, the rotating base 101 includes a hydraulic motor and a worm gear mechanism, the hydraulic motor is fixed on the chassis, and the worm 113 is fixed on the output shaft of the hydraulic motor to drive the worm 113 to rotate through the hydraulic motor. The worm wheel 114 is rotatably arranged on the chassis, and the worm 113 is matched with the worm wheel 114 The worm 113 drives the worm wheel 114 to rotate; in this embodiment, preferably, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com