Continuous mining method of medium-thick heavy pitch ore body empty field

A mining method and steep inclination technology, which are applied in the field of continuous open-field mining of medium-thick steeply inclined ore bodies, can solve the problems of complex recovery process, large amount of resources occupied by reserved ore pillars, restricting the development of mines, etc., and achieve efficient recovery of mineral resources. , low-cost mining, the effect of promoting normal and orderly operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

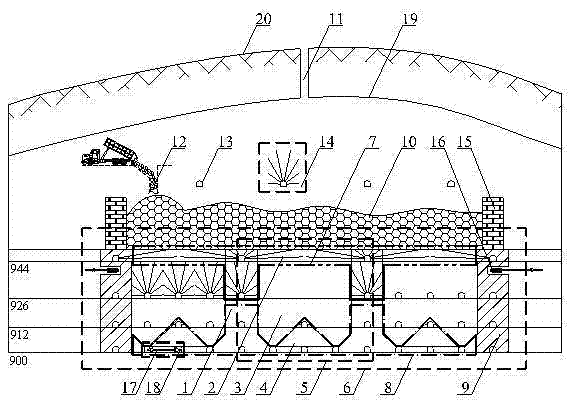

[0020] Such as figure 1 As shown, in a lead-zinc mine, the inclination angle of the ore body is more than 65°, and the average thickness is 24m. The complex empty area formed by years of open-field mining above the middle section of 950m has not been treated, and the hidden dangers are prominent, which seriously restricts the efficient mining of resources in the lower part of the mine. For the ore body below the middle section of 950m in the lead-zinc mine, the open-field continuous mining method of the medium-thick steeply inclined ore body of the present invention is adopted. The specific implementation is as follows:

[0021] 1. Divide the mining area and the mining units in the mining area: determine a continuous mining area 6 between the 14-20 exploration line, and arrange a total of 3 mining units 5 in the mining area 6. The mining unit 5 is arranged vertically to the ore body. The mining unit 5 temporary columns 1, 6 isolation zones 9 in the mining area, mining unit 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com