Device assembly for tensioning fork ear type stay rope or steel pull rod and tensioning construction method of device assembly

A steel tie rod and fork lug technology, applied in the field of prestressed structure construction devices, can solve problems such as unfavorable local stress control, difficulty in achieving tension control, uneven anchoring length, etc. The effect that is beneficial to the implementation of tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

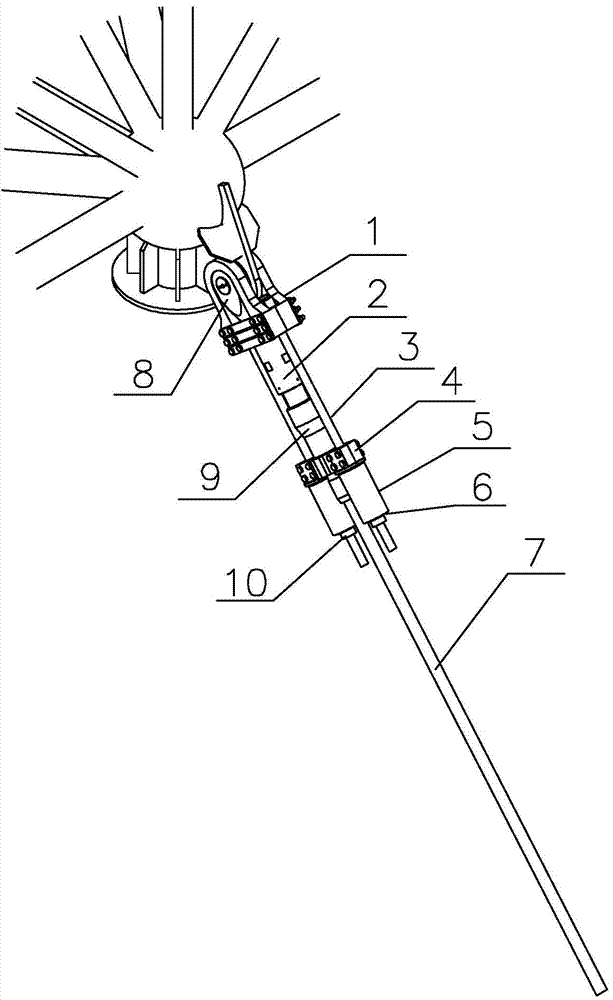

[0035] A device assembly for tensioning a fork lug type cable or a steel pull rod. The fork lug type pull cable or the fork lug steel pull rod includes a cable body or a steel pull rod 7, and is located on the cable body or the steel pull rod 7 The fork ears 8 at both ends and the adjusting tube 2 and the extension tube 9 on the near one end of the fork ears;

[0036] The device components for tensioning fork lug type cables or steel rods include: reaction frame 1, tension rod 3, pole beam 4 and jack 5 (see figure 1 );

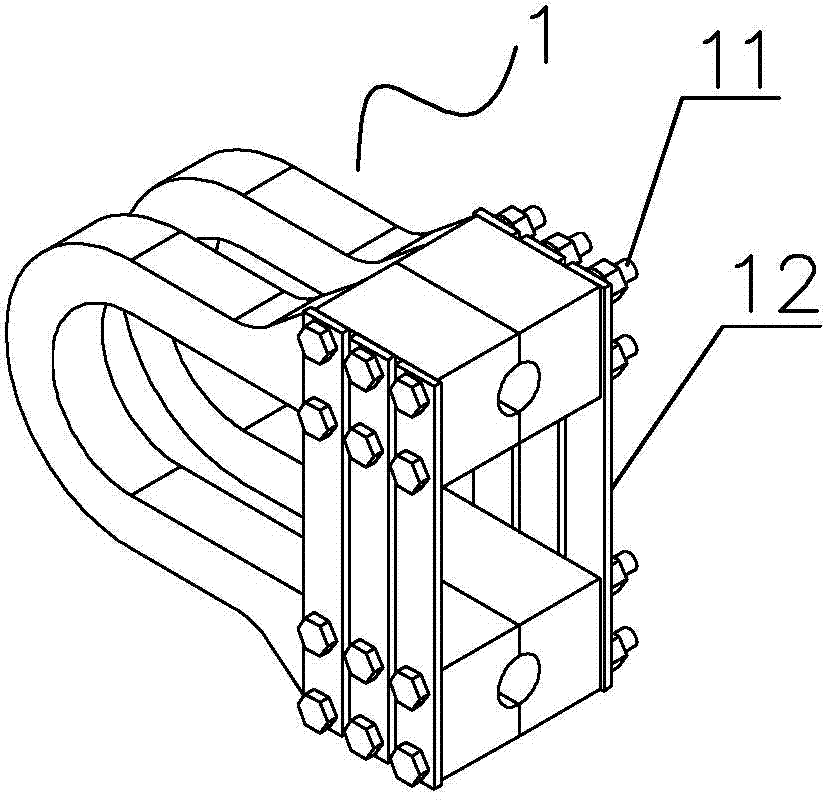

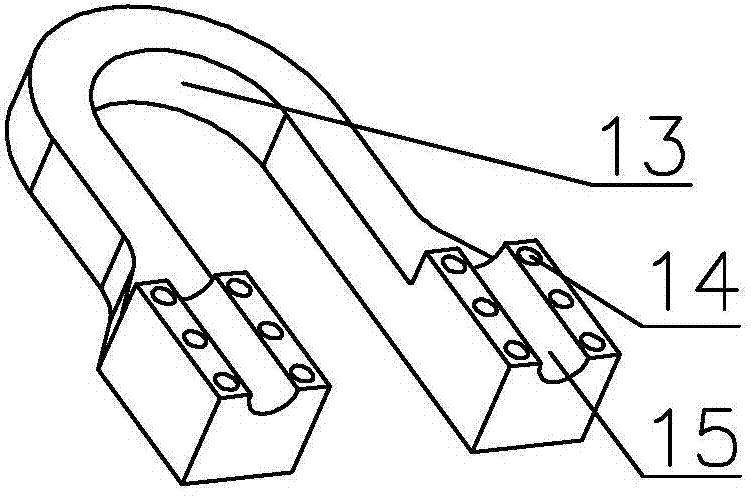

[0037] The reaction force frame 1 is similar to a "U"-shaped structure and is divided into two pieces; the inner arc size of the reaction force frame is 3-5mm larger than that of the upper end surface of the fork lug, and the opening of the "U"-shaped structure is designed to be stepped. Bolt holes 14 and semicircular grooves Ⅰ15 for the tension rod for passing through the tension rod (see diagram 2-1 , Figure 2-2 );

[0038] The pole beam 4 is a split in two halv...

Embodiment 2

[0041] A tension construction method for fork lug type cables or steel rods at both ends, which includes the following steps:

[0042] A. Install the reaction frame: Install the two halves of the reaction frame 1 on both sides of the fork lug 8 of the fork lug cable or steel rod. The inner arc 13 of the reaction frame and the outer arc surface of the fork lug 8 Contact; then through the bolt 11 and the connecting plate 12 to fix the two pieces of reaction frame 1 on the fork lug type cable or steel pull rod fork lug, two pull rod semi-circular groove I merge into a through hole;

[0043] B. Install the pole pole beam: install the pole pole beam 4 at the position of the cable body or steel tie rod 7 extension tube 9; when installing, fasten the large semicircular groove 44 of the pole pole beam on the cable body or steel tie rod, and connect the pole pole beam through bolts 41 4Fixed, two tie rod semi-circular grooves Ⅱ 43 are combined into a circular through hole for the tension ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com