Pneumatic tire

A technology of pneumatic tires and tires, which is applied to tire parts, tire tread/tread pattern, transportation and packaging, etc., to achieve good control stability and small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

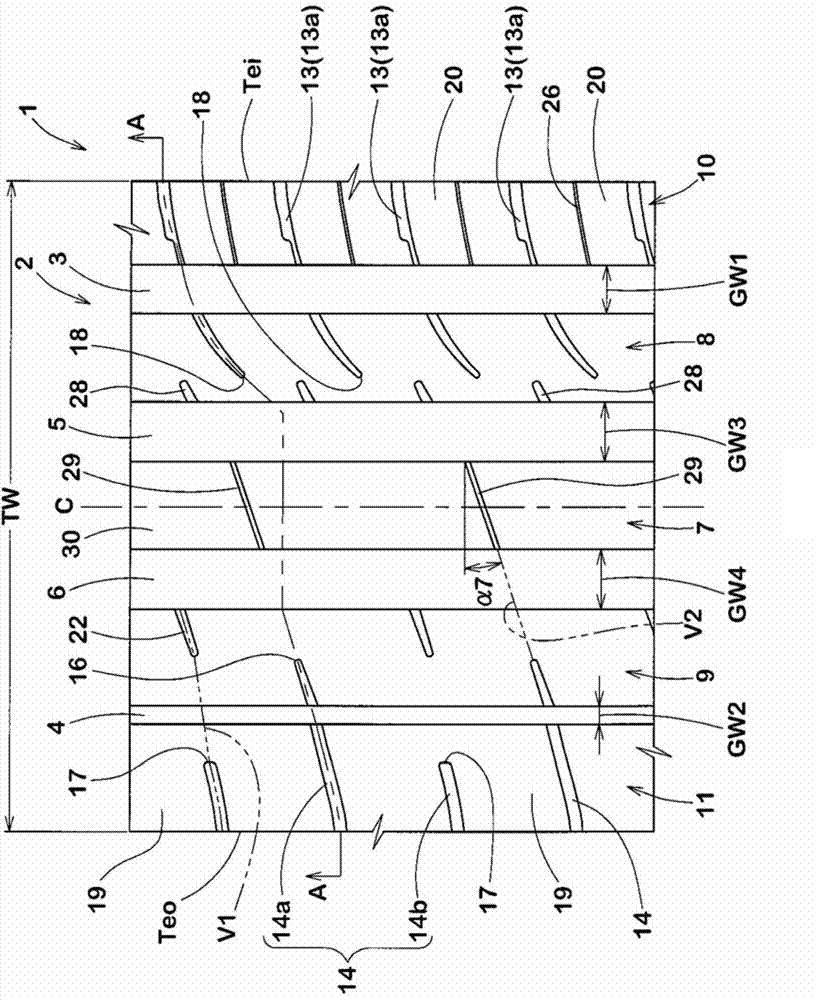

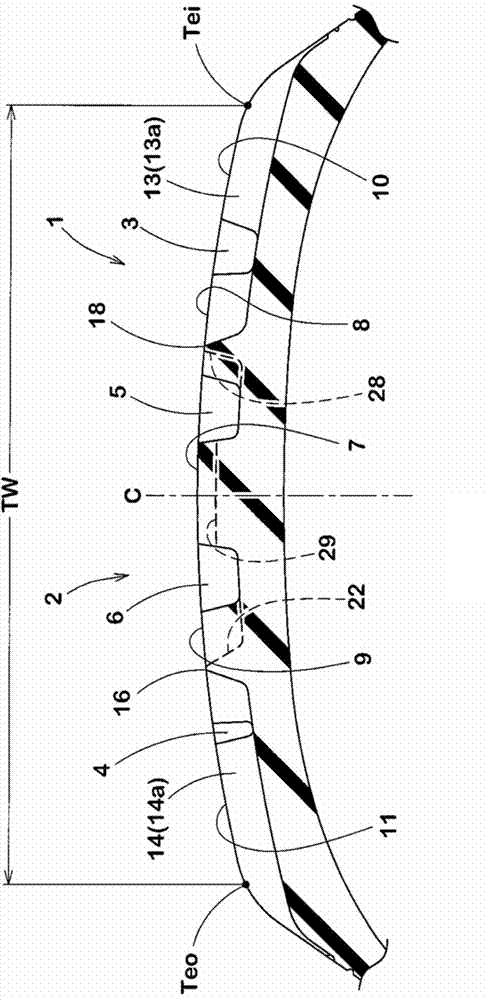

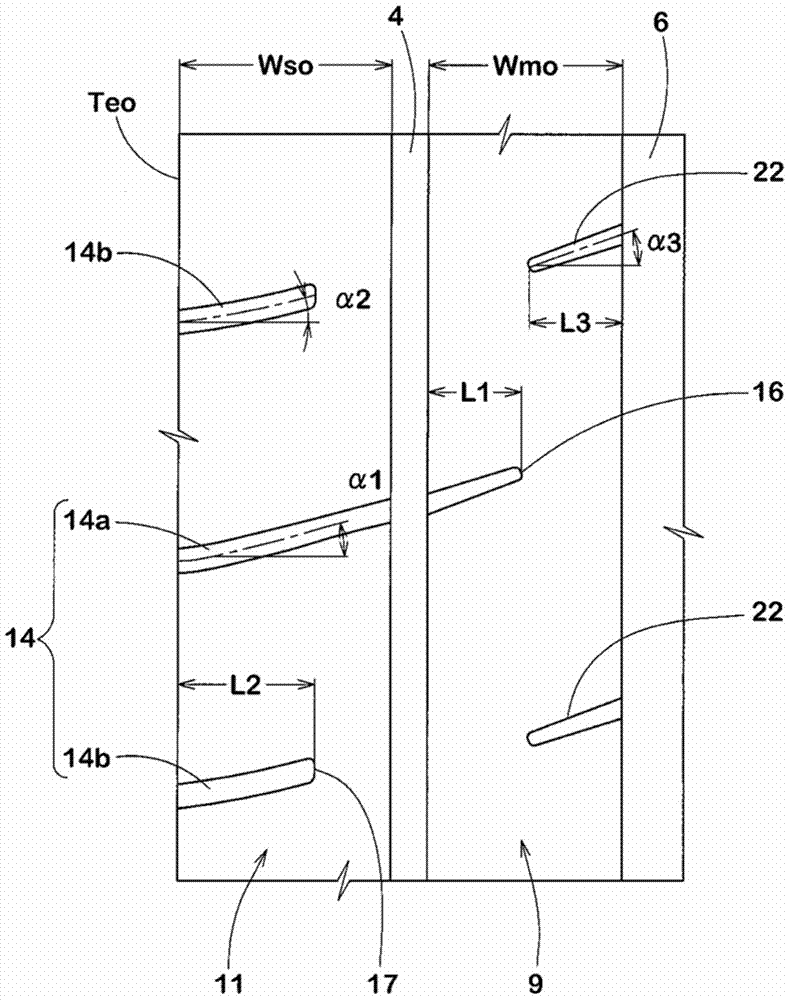

[0079] The tire of Example 1 has the above figure 1 tread pattern. Example 2 has Figure 6 Tread pattern shown. In Example 2, such as Figure 6 As shown, compared with Embodiment 1, the central lateral grooves are arranged half pitch staggered along the tire circumferential direction. The tire of the comparative example is a tire in which the second outer shoulder lateral groove of Example 1 extends toward the inner side in the tire axial direction beyond the outer shoulder main groove. Thus, the number of first inner shoulder lateral grooves is set to be equal to the number of first outer shoulder lateral grooves. The test method is as follows.

[0080]

[0081] A professional driver drives a test vehicle equipped with test tires on a test track, and evaluates the steering stability of each tire sensory, including steering wheel responsiveness, rigidity, and grip. The results are represented by the comparative example with a rating of 100, and the larger the numerical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com