Vehicle wire drawing device and coating-free railway vehicle

A car body and wire drawing technology, which is applied to railway car body parts, transport passenger cars, transportation and packaging, etc., can solve the problems of time-consuming, labor-intensive, cumbersome process, etc., and achieve the effect of correcting deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] The car body wire drawing device of the present invention is applied to the processing of car body parts, especially the wire drawing of the car body surface such as side walls and the like.

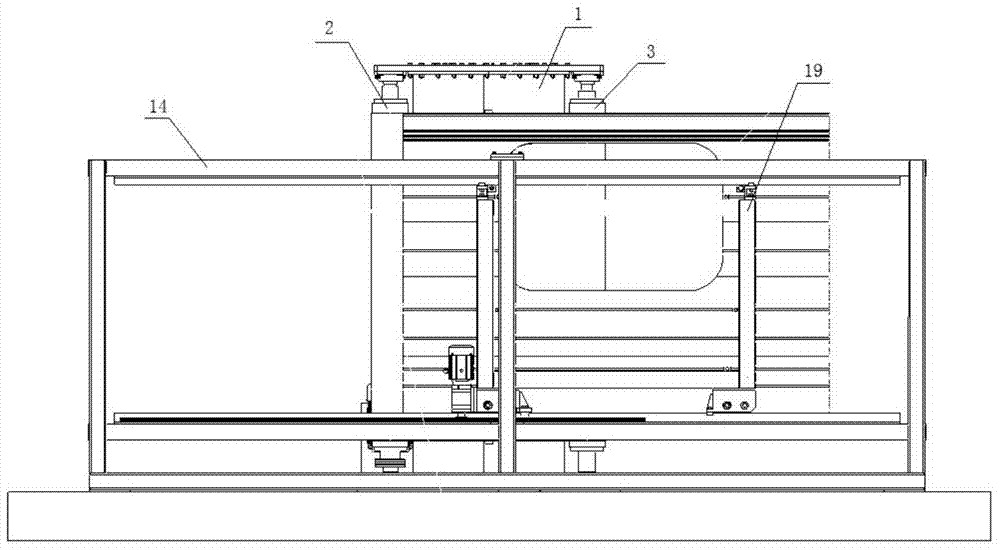

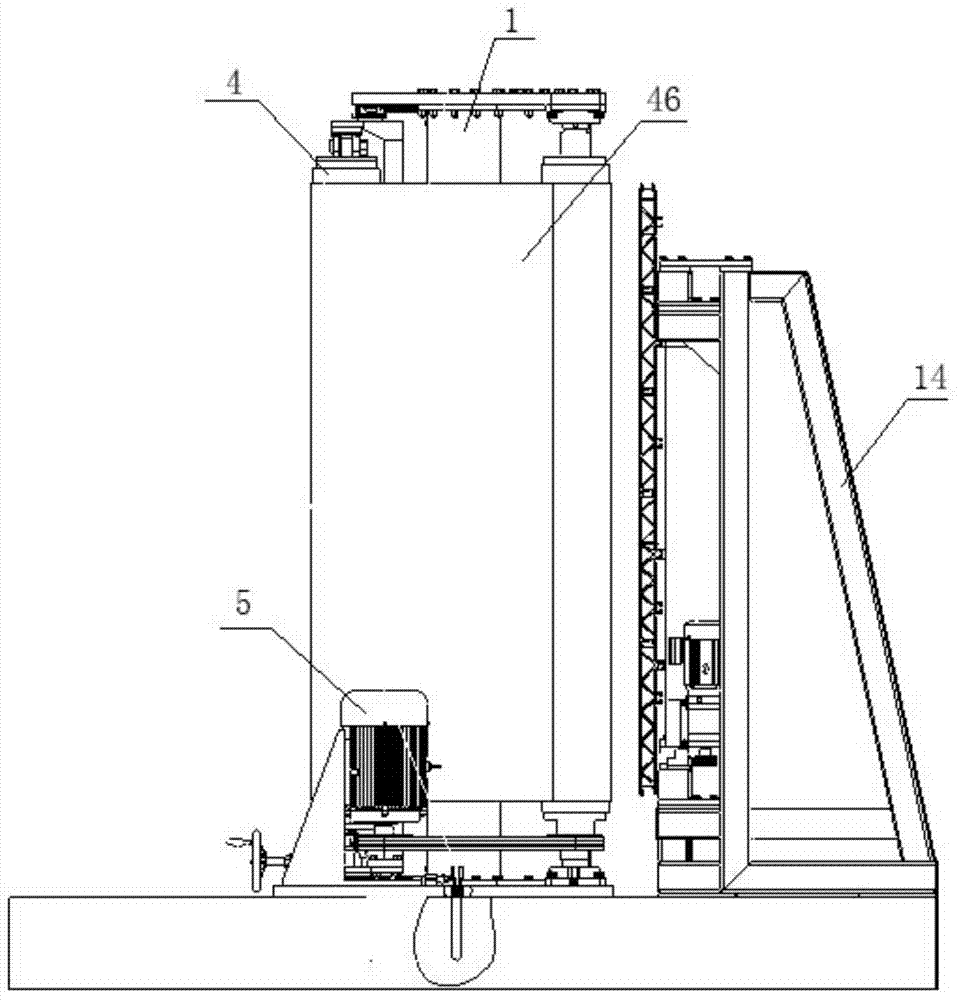

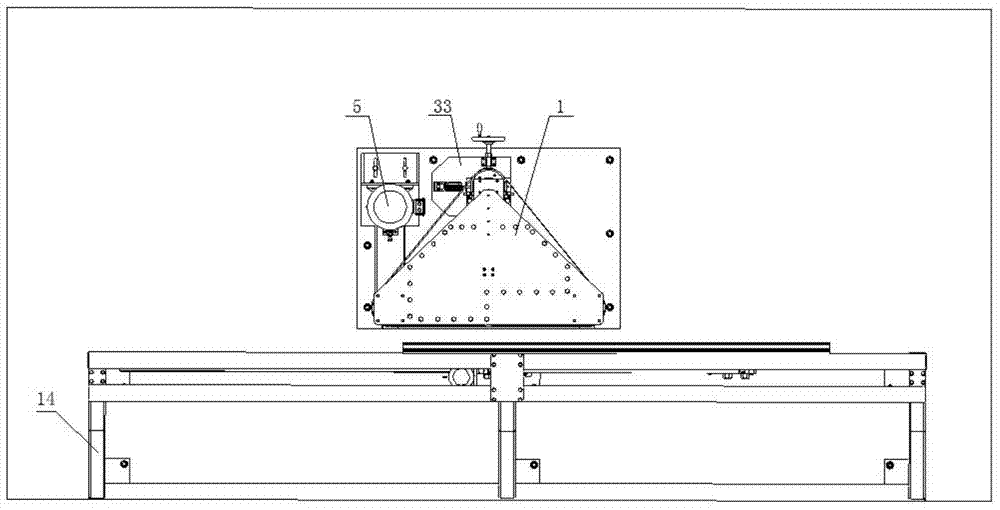

[0072] Such as Figure 1 to Figure 3 As shown, the car body wire drawing device consists of two parts, one is the walking device, and the other is the main body of the wire drawing machine. The traveling device is used for the fixation and displacement of the car body parts to be processed, and the wire drawing machine is used for wire drawing of the car body parts to be processed.

[0073] The wire drawing machine includes a column 1, a driving roller 2 distributed in a triangle, a support roller 3 and a tension roller 4, and an abrasive belt 46 is respectively connected to the driving roller 2, support roller 3 and tension roller 4 by belt transmission. The driving roller 2, the support roller The roller 3 and the tension roller 4 are arranged on the periphery of the column 1 i...

Embodiment 2

[0104] Such as Figure 18 , 19 As shown, the car body wire drawing device consists of two parts, one part is the workpiece fixing device (not shown in the figure), and the other part is the main body of the wire drawing machine. The workpiece fixing device is used for fixing the car body parts to be processed, and the wire drawing machine is used for wire drawing of the car body parts to be processed.

[0105] The wire drawing machine includes a wire drawing machine support frame 43, a triangular distribution of drive roll 2, support roll 3 and tension roll 4, the abrasive belt 46 is respectively connected with the drive roll 2, support roll 3 and tension roll 4 as a belt drive, and the wire drawing The top of the machine support frame 43 is provided with a driving motor mounting seat, and a driving motor 5 is arranged in the mounting seat, and the driving motor 5 is connected with the driving roller 2 by a V-shaped belt to drive the driving roller 2 to rotate. The car body ...

Embodiment 3

[0109] Such as Figure 20 to Figure 22 As shown in the figure, a non-painted car body drawing factory building includes four areas, namely the No. 1 preparation station 48, the drawing workshop 49, the No. 2 preparation station 50, and the material and tool storage area 51. The four areas are arranged in a straight line in turn. . The drawing workshop 49 is arranged between the No. 1 preparation station 48 and the No. 2 preparation station 50, and is closed.

[0110] A vehicle body displacement track 52 is set, and the vehicle body displacement track 52 runs through the No. 1 preparation station 48, the drawing workshop 49, and the No. 2 preparation station 50. On the car body displacement track 52, a traction trolley is arranged, and the traction trolley is used to drive the whole row of rail vehicles to move along the No. 1 preparation platform 48, the drawing workshop 49, and the No. 2 preparation platform 50.

[0111] A plurality of wire drawing devices in the first embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com