Cereal vibrating and impurity removing device

A technology of grain and induced draft device, which is applied in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve the problems of slow artificial screening efficiency and surrounding air pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

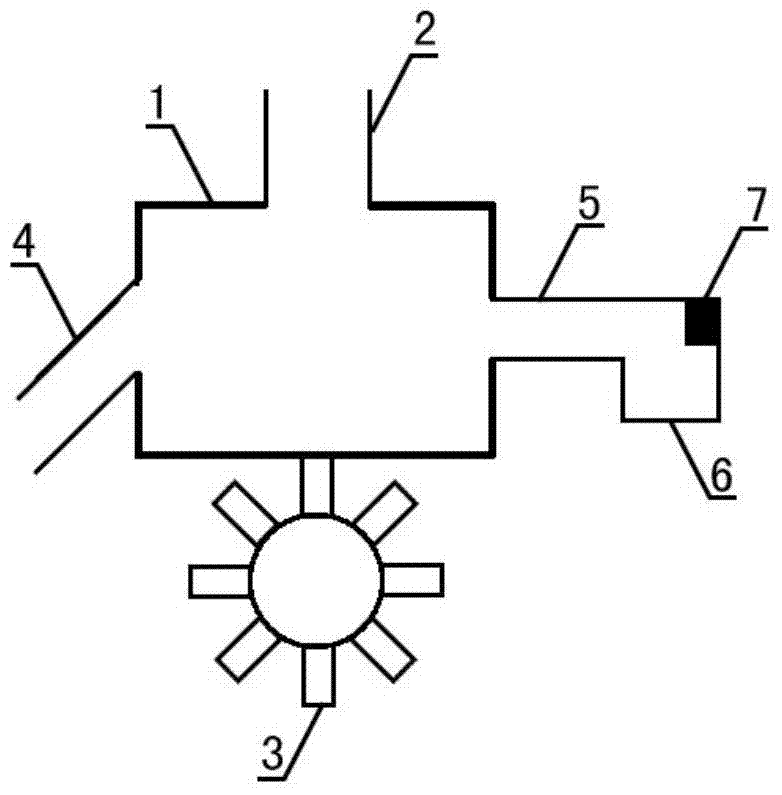

[0013] Embodiment: as shown in the accompanying drawing. The grain vibration and impurity removal device includes a silo (1), an air induction device (2) is arranged outside the silo, a motor (3) is arranged at the base of the silo, and an adsorption duct (4) is arranged on the air induction device (2) , a conveyor belt (5) is set in the silo, and a discharge basket (6) is set at the rear end of the silo. When in use, the grain is put into the silo (1), the induction motor (3) is started, and the air induction device (2 ) blows a strong wind to absorb grain impurities through the adsorption pipe (4), and the filtered grain is transported to the discharge basket (6) through the conveyor belt (5).

[0014] In the grain vibration impurity removal device, the position of the adsorption pipe (4) can be rotated to expand the adsorption range.

[0015] The grain vibration impurity removal device is provided with an induction device (7) in the discharge basket, and a prompt message i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com