a drying equipment

The technology of drying equipment and drying tunnel is applied in the direction of pretreatment surface, coating, device for coating liquid on the surface, etc., which can solve the problems of excessive workpiece drying, energy waste, and poor workpiece drying effect, etc. Achieve the effect of meeting drying needs and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

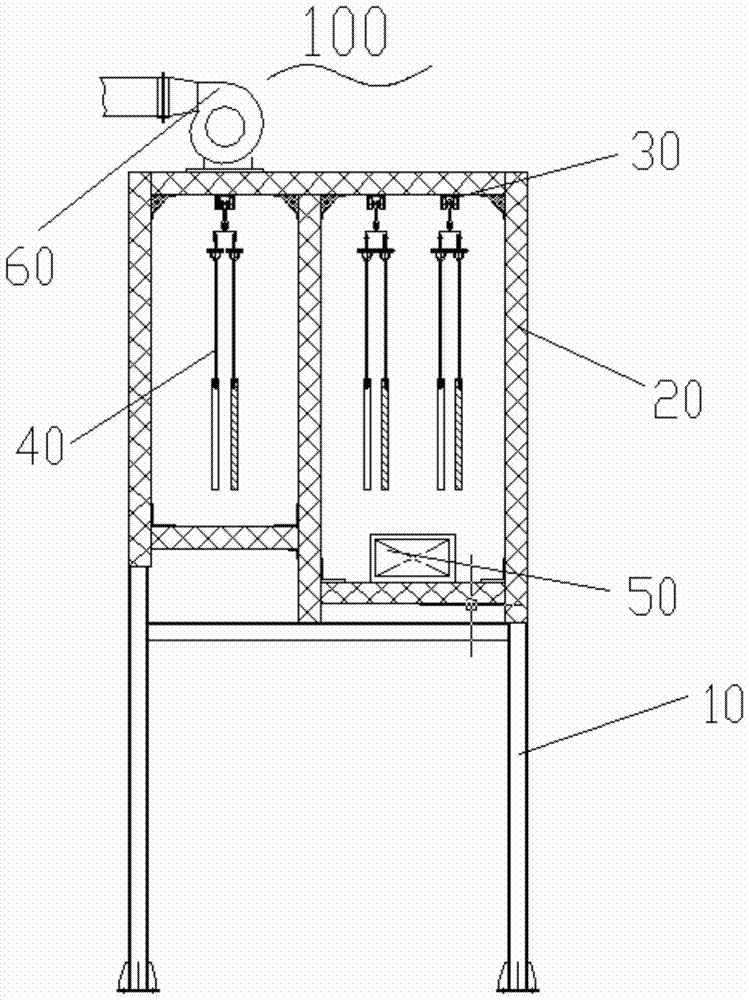

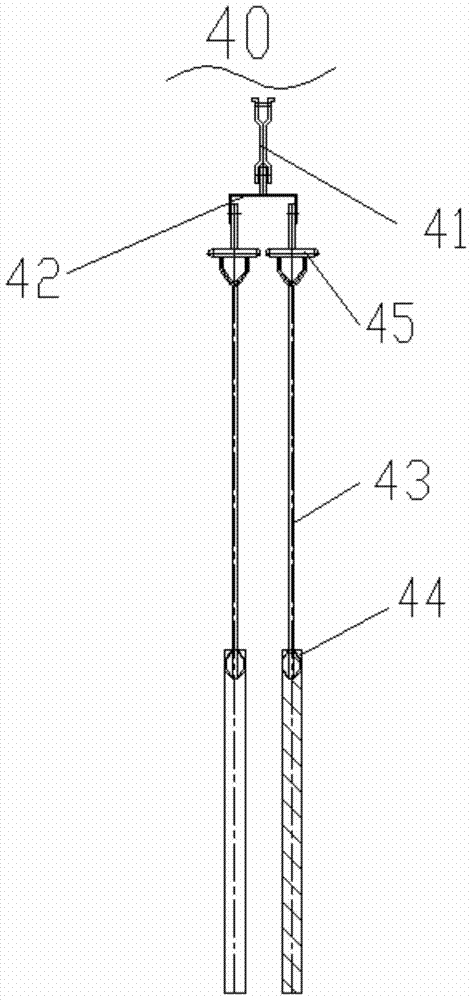

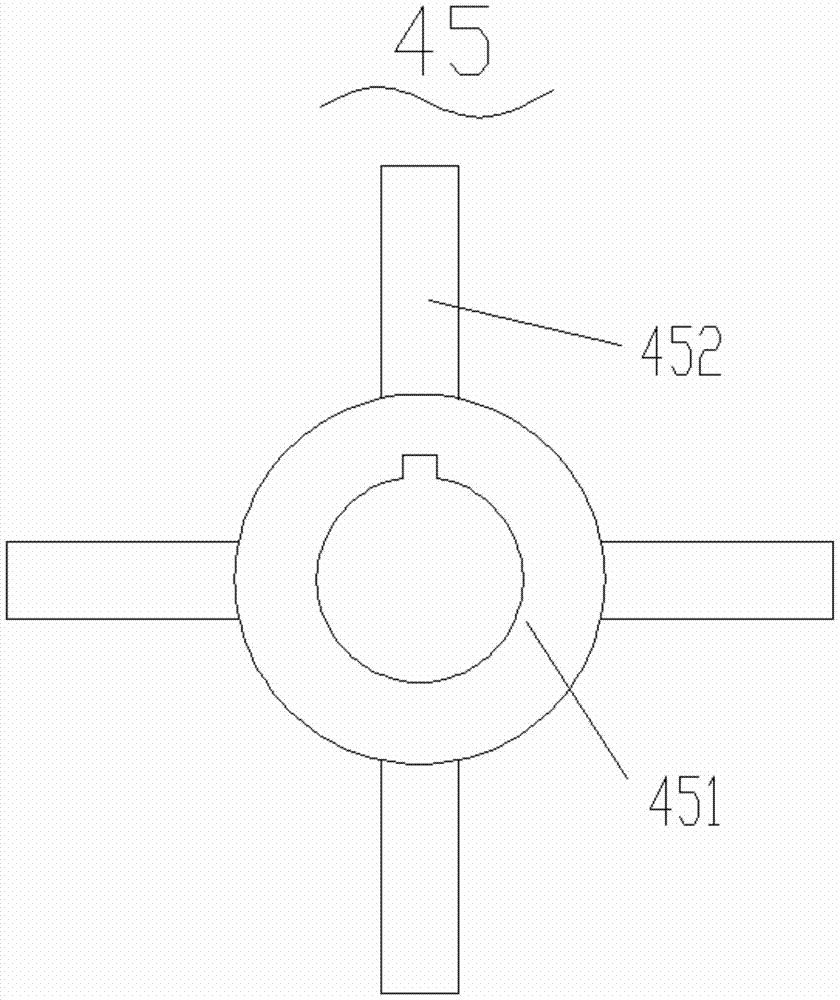

[0022] see figure 1 , the drying equipment 100 provided by the preferred embodiment of the present invention includes a bracket 10, a drying tunnel 20, a conveying chain 30, a rotating hanger 40 and a tool for drying the workpiece mounted on the rotating hanger 40. Steam pipe 50 and fan 60.

[0023] The drying tunnel 20 is arranged on the support 10 , and the side of the drying tunnel 20 away from the support 10 is used to set the conveying chain 30 , and each conveying chain 30 is hung with a rotating hanger 40 . The steam pipe 50 is arranged on the side of the drying tunnel 20 adjacent to the support 10, and conducts steam in the steam pipe 50, so that the drying equipment 100 can be heated by the heat transfer of the conduction steam during use. Realize the drying treatment of the workpieces mounted on the rotary rack 40; the fan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com