Water soluble surfactant composition and ink composition comprinsing the same

A surfactant and composition technology, applied in the field of water-soluble surfactant compositions, can solve the problems of insufficient, poor fluid properties, and inability to coat at high speed, and achieve practical advantages, small contact angles, and low dynamic surface tension. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

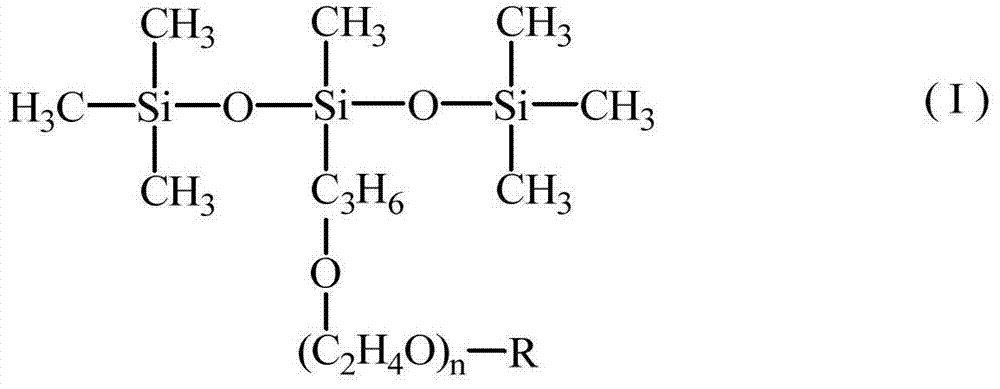

Method used

Image

Examples

Embodiment 1

[0061] 80 parts of (A-1) heated to 50° C. were put into a container with a blade stirrer, 10 parts of propylene glycol and 10 parts of water were slowly added, and stirred for 1 hour to obtain a surfactant composition (hereinafter referred to as called M-1).

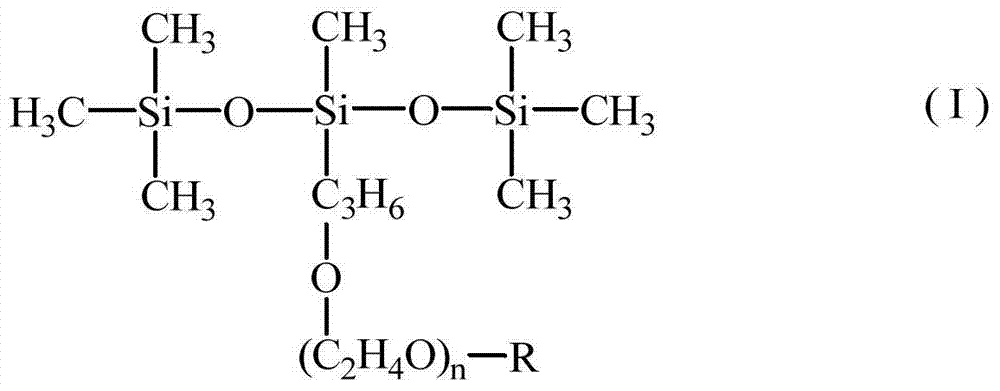

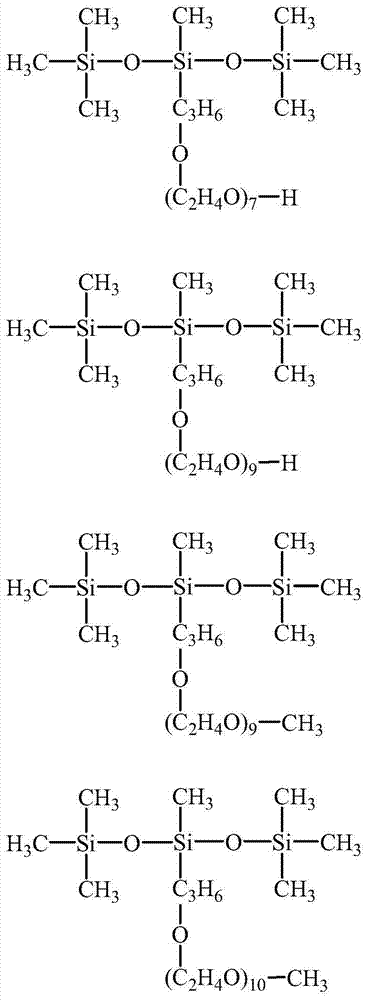

[0062] 【Chemical 4】

[0063]

Embodiment 2~4、 comparative example 1~9

[0065] Surfactant compositions M-2 to M-13 were obtained in the same manner as in Example 1 with the compounding compositions shown in Table 1.

[0066] 【Chemical 5】

[0067]

[0068] 【Chemical 6】

[0069]

[0070] 【Table 1】

[0071]

[0072] In addition, the measurement of each physical property was performed as follows. The results are shown in Table 2.

[0073]

[0074] The appearance of the aqueous solution and the presence or absence of insoluble matter were checked.

[0075] ○: The aqueous solution is transparent, and no insoluble matter is found

[0076] △: The aqueous solution was cloudy, but no insoluble matter was found

[0077] ×: A part of insoluble matter was found

[0078]

[0079]The dynamic surface tension at 1 Hz and 10 Hz of a 0.1% aqueous solution of the surfactant composition was measured using a bubble pressure type dynamic surface tensiometer Kruss BP-100 manufactured by KRUSS Corporation.

[0080]

[0081] The contact angle after dr...

Embodiment 5

[0086] As the ink, after slowly adding 5 parts of Kara Bradke S170 (manufactured by Degussa Co., Ltd.) as a black pigment to 70 parts of ion-exchanged water while stirring with a blade mixer, add 1 part of surfactant composition M-1, 10 1 part polyethylene glycol (molecular weight 200), 15 parts glycerin, and after stirring for 1 hour, a black ink composition (hereinafter referred to as ℓ-1) was obtained.

[0087] Furthermore, a magenta pigment (C.I. Pigment Red 122), a cyan pigment (C.I. Pigment Blue 15:3), and a yellow pigment (C.I. Pigment Yellow 74) were used instead of the above-mentioned black pigment, and magenta (C.I. Pigment Yellow 74) was produced in the same manner as above. M), cyan (C), yellow (Y) ink.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com