Gravity spraying washer for dusty gas

A scrubber and gas technology, applied in chemical instruments and methods, using liquid separation agents, and dispersing particle separation, etc., can solve the problems of unsatisfactory purification effect and dust-containing gas cannot be purified, and achieve stable purification effect and low resistance. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical scheme of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

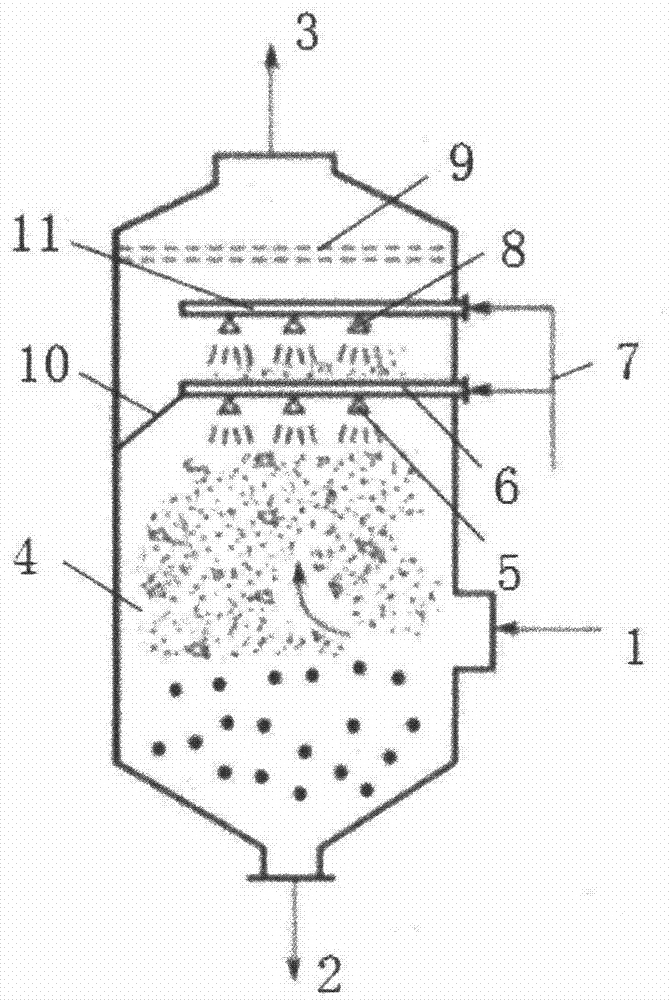

[0015] Such as figure 1 As shown, a gravity spray scrubber for dusty gas includes a shell 4, preferably, the shell 4 is cylindrical. The side wall of the housing 4 is provided with a dusty gas inlet 1 , the top of the housing 4 is provided with an exhaust port 3 for purified gas and the bottom is provided with a sewage outlet 2 .

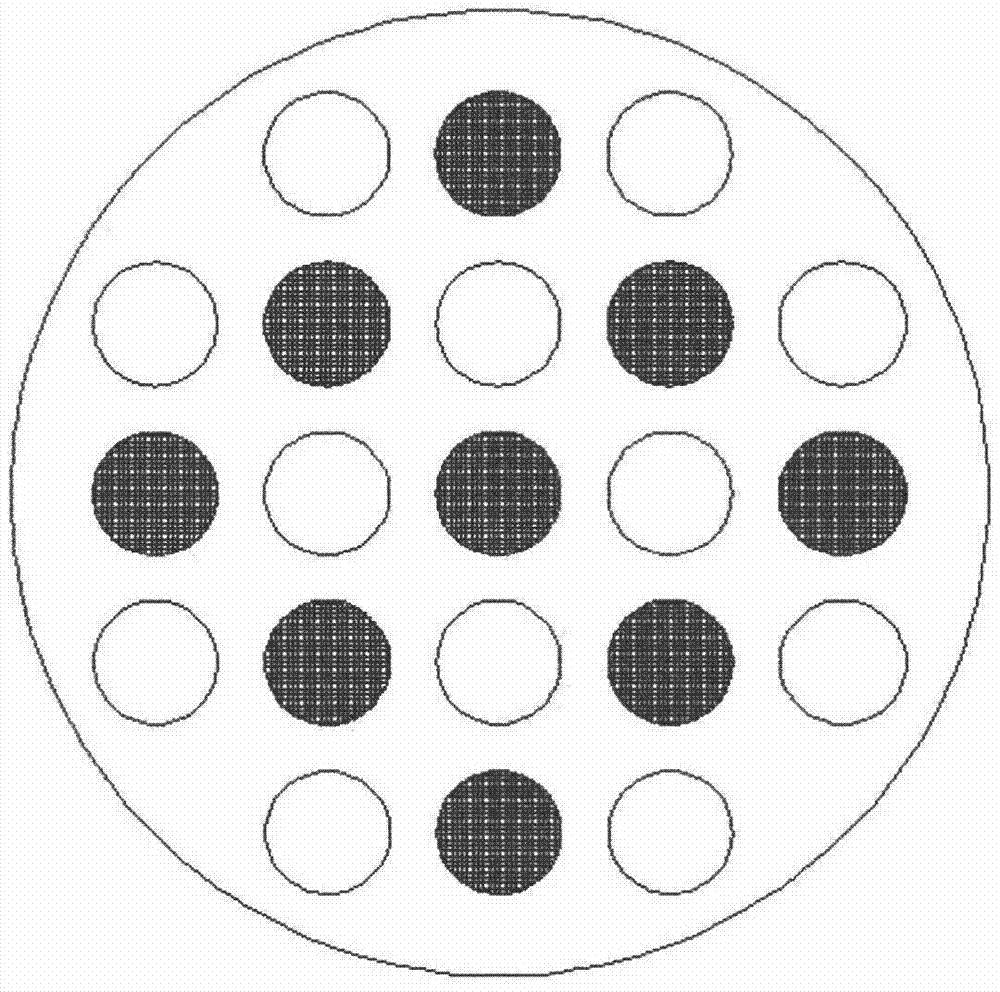

[0016] A certain distance at the top of the dust-laden gas inlet 1 in the housing 4 is provided with a number of equally spaced and parallel first clean water pipe groups 6 , and a number of equally spaced water pipe groups 6 are arranged directly below the first clean water pipe group 6 . The first nozzle group 5, a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com