Carbon-free self-propelled trolley with automatic steering function

A self-propelled trolley and automatic steering technology, applied in the field of mechanical design, can solve problems such as inability to put into production, inaccurate steering control, and high processing costs, and achieve the effects of simple structure, precise and reliable system control, and low processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

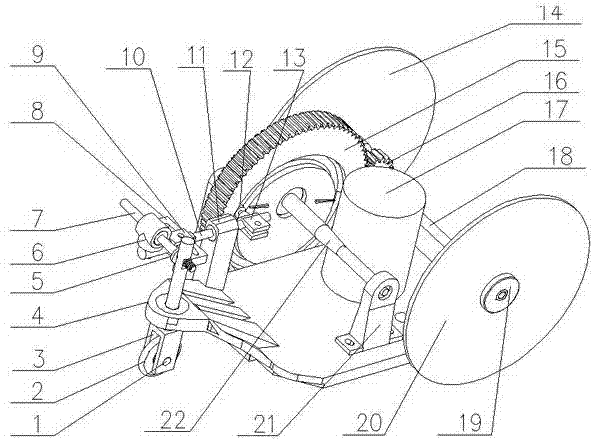

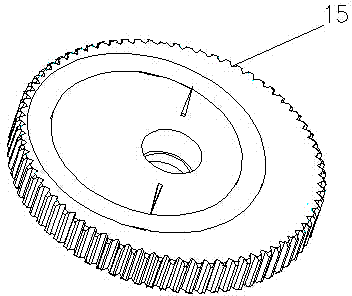

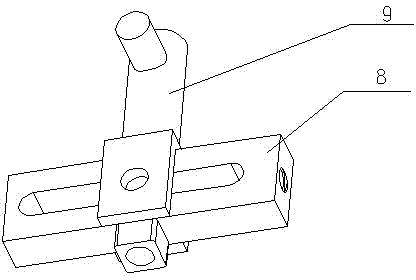

[0023] figure 1 It is a structural schematic diagram of a carbon-free self-propelled trolley with automatic reversing function in the present invention, which consists of a guide wheel shaft 1, a guide wheel 2, a front fork 3, a bottom plate 4, a lock nut 5, a transfer pair 6, a rocker 7, and an adjustment block 8. Front push rod 9, rear push rod 10, push rod support frame 11, needle roller bearing 12, holding card 13, driving wheel 14, large gear 15, pinion gear 16, weight 17, driven shaft 18, deep groove Ball bearing 19, driven wheel 20, bearing housing 21, drive shaft 22 constitute.

[0024] The chassis includes a base plate 4, a push rod support frame 11, a drive shaft bearing seat 21 figure 1 The push rod support frame 11 is installed on the front middle of the base plate 4 before the drive shaft bearing seat; the drive shaft bearing seat 21 is installed in the middle of the base plate 4 in parallel; the driven shaft bearing seat is installed symmetrically and parallelly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com