Ridging mulch applicator

A technology of a ridge mulching machine and a traction machine, which is applied in the field of ridge mulching and mulching machines, can solve the problem that the full mulching equipment cannot effectively complete ridge mulching, fertilization, and spraying at the same time, and achieves safe and reliable operation of the whole machine. Type flat standard, full-featured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

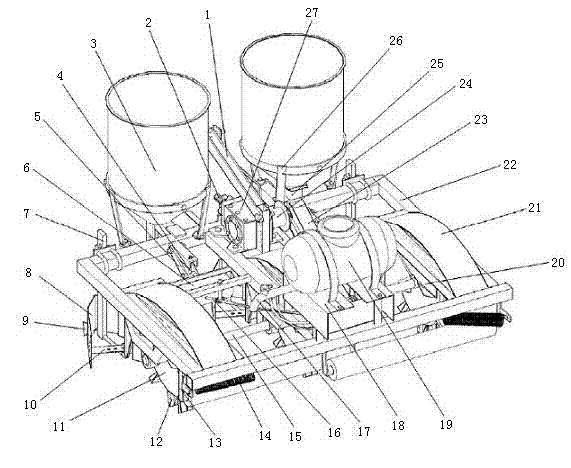

[0024] A specific example is provided below: the ridge laminating machine is connected with the four-wheel tractor through the connecting frame, the power is transmitted to the gearbox through the transmission main shaft, and then transmitted to the output shaft after the gearbox changes speed, and the output shaft passes through the sprocket in the sprocket box Drive the rotation of the soil throwing plate shaft, and the soil throwing plate will rotate clockwise with the soil throwing device, and the soil throwing device will take soil from the ground, and with the rotation of the soil throwing plate, the soil will be thrown out from the top of the mulch and pressed on the laid mulch , The plastic film is hung on the film rack and rolls with the rollers on the film rack. There is a superimposed part between the two plastic films, which makes the whole machine form a full film effect during the film laying process. As the whole machine moves forward, three ridge plowshares plow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com