Fastening part structure and molding device of resin parts

A technology of fastening parts and resins, applied to threaded fasteners, deformable fasteners, household components, etc., to achieve the effect of improving workability, improving fluidity, and preventing misassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

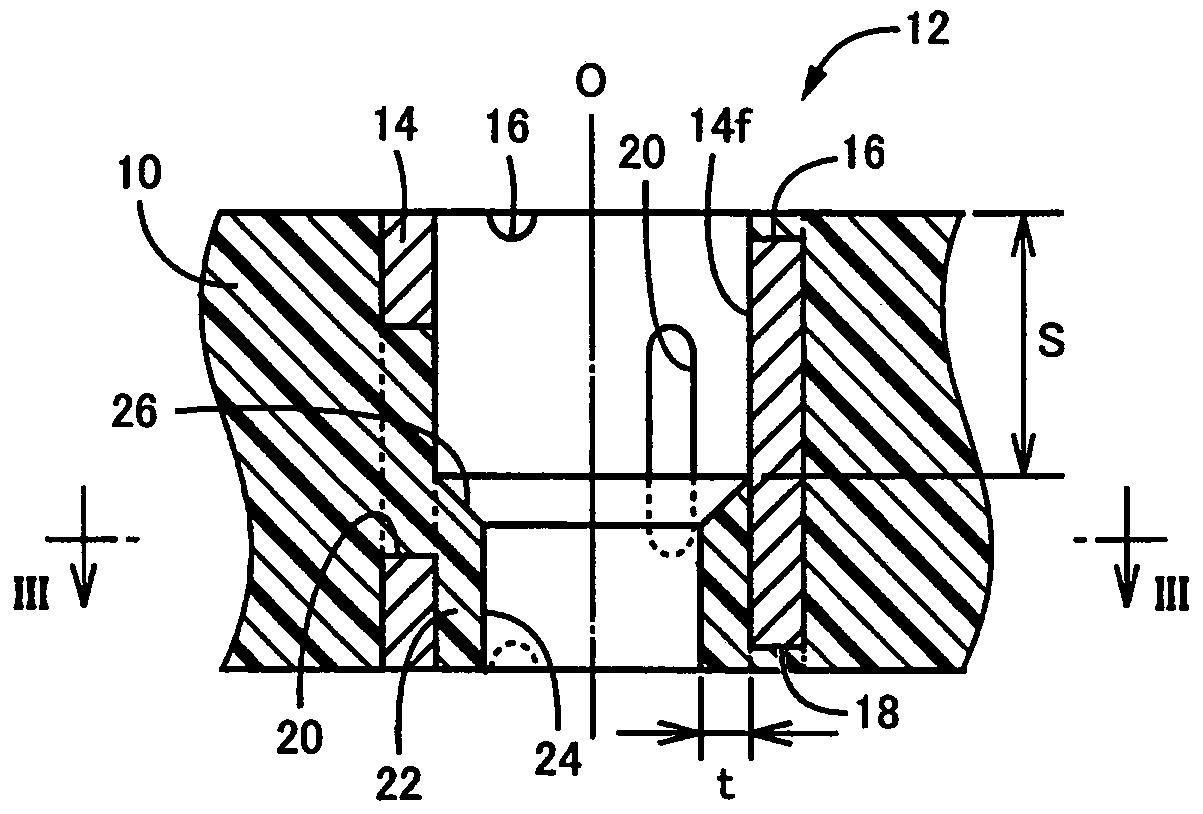

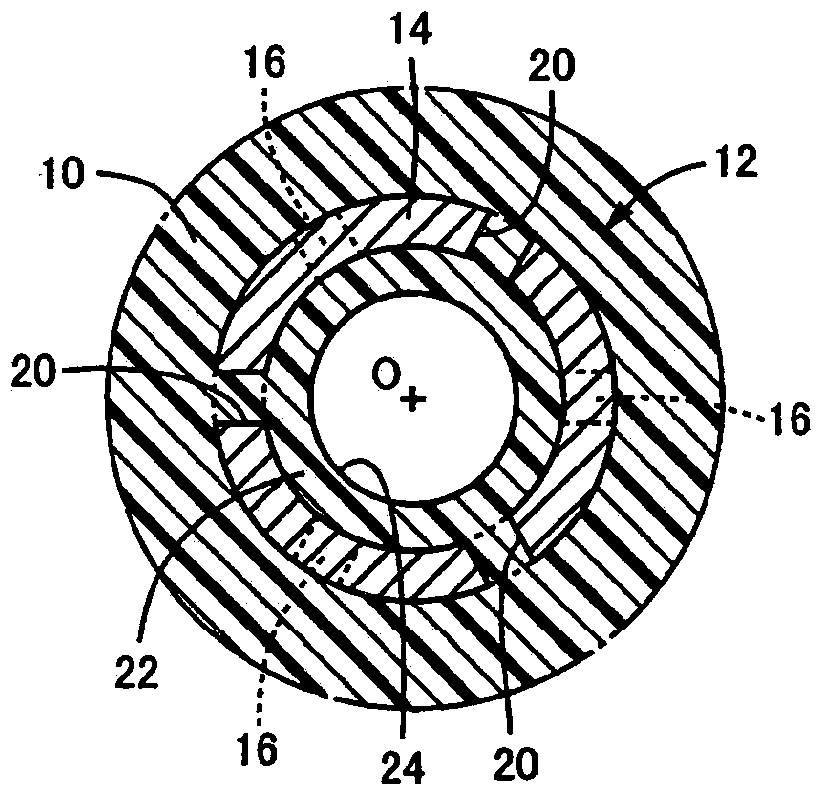

[0041] Refer to the attachment below Figure one The embodiments of the present invention will be described in detail.

[0042] figure 1 It is a diagram explaining the structure of the fastening portion as an embodiment of the present invention, and is a longitudinal cross-sectional view of the fastening portion 12 provided in the resin part 10, which is figure 2 A vertical cross-sectional view of the I-I arrowed part in. figure 2 Is viewed from above the axis figure 1 A plan view of the vicinity of the fastening portion 12, image 3 Yes figure 1 The cross-sectional view of the part in the direction of III-III. In addition, Figure 4 Is a diagram separately showing the sleeve 14 used in the fastening portion 12, Figure 5 The longitudinal section view of the IV-IV direction part in Figure 5 From the axial view Figure 4 A top view of the casing 14. The sleeve 14 corresponds to a cylindrical member, and in this embodiment is a cylindrical steel pipe.

[0043] In the aforement...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com