Superaudio large-power quenching numerical control machine tool energy parameter and technological parameter management device

A technology of CNC machine tools and management devices, applied in the direction of digital control, electrical program control, etc., can solve the problems of poor process stability and quality of quenched products, low integration of quenching process system control, etc., to improve processing quality, reasonable structure design, The effect of improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

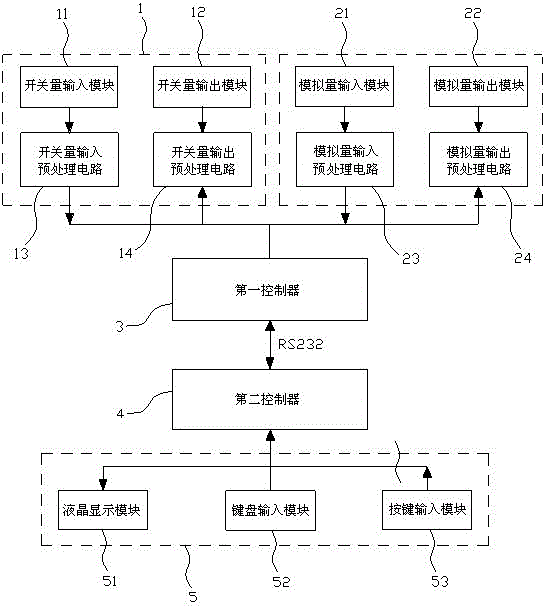

[0026] Such as Figures 1 to 10 As shown, the energy parameter and process parameter management system of the ultra-audio frequency high-power quenching CNC machine tool of the present invention includes a switching value preprocessing unit 1, an analog quantity preprocessing unit 2, a first controller 3, a second controller 4 and an input / output Unit 5.

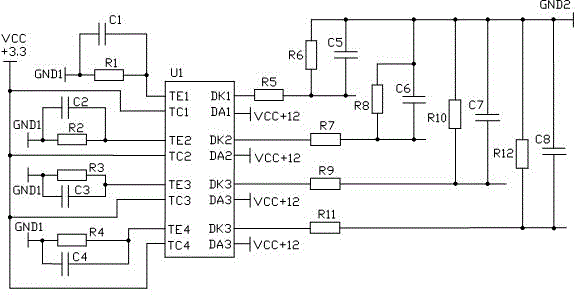

[0027] Such as image 3 , 4 , the switching value pre-processing unit 1 is electrically connected to the first controller 3, and it includes a switching value input module 11 and a switching value output module 12; wherein, the switching value input module 11 is used for isolating and transforming switching signals and anti-shaking After processing, it enters the input port of the I / O unit of the first controller 3 , which is electrically connected to the first controller 3 through the switching value input preprocessing circuit 13 . The switching value input preprocessing circuit 13 is composed of an input terminal RC ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com