Four-dimensional measuring method of pulsating flame based on optical deflection tomography

A technology of pulsating flames and measurement methods, applied in the field of laser technology applications, can solve problems such as the inability to meet the requirements of high-precision measurement of turbulent combustion with complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

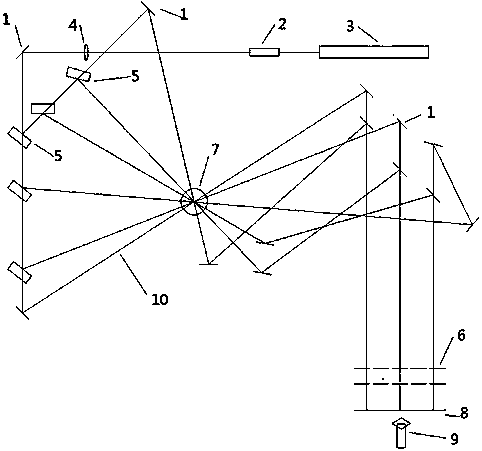

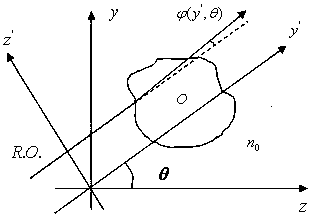

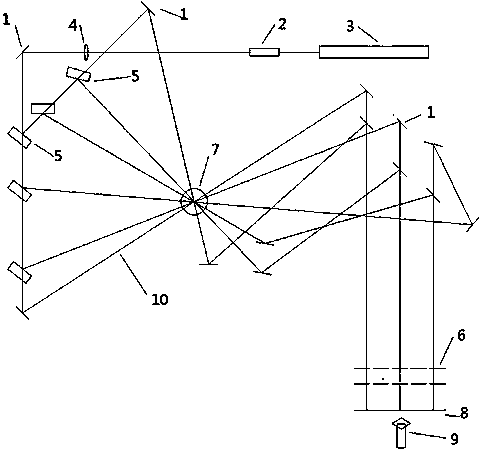

[0033] see figure 1 and figure 2 As shown, the present invention builds a 4D-CT multi-view projection ordered array deflection imaging system, and determines the best sampling angle according to the structural characteristics of the measured flow field, and expands and collimates the laser beam emitted by the laser source. After the filter, a beam splitter is used to perform secondary beam splitting to generate multiple projected beams 10, thereby generating a Moiré deflection fringe array; using fringe image processing technology based on wavefront recovery, the light deflection information of projected fringes is extracted ; Construct a compressed sensing reconstruction algorithm based on deflection angle correction and reconstruction to perform inversion calculation on the deflection projection information, and obtain the two-dimensional parameter distribution of different fringe pattern sections; use the single threshold segmentation method to perform threshold segmentati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com