Self-balancing reinforced concrete bonding and anchoring performance test instrument

A technology of reinforced concrete and anchorage performance, applied in instruments, measuring devices, mechanical devices, etc., can solve the problems of error, complicated operation, increase unsafe factors, etc., achieve synchronous measurement, ensure safety, and save manpower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

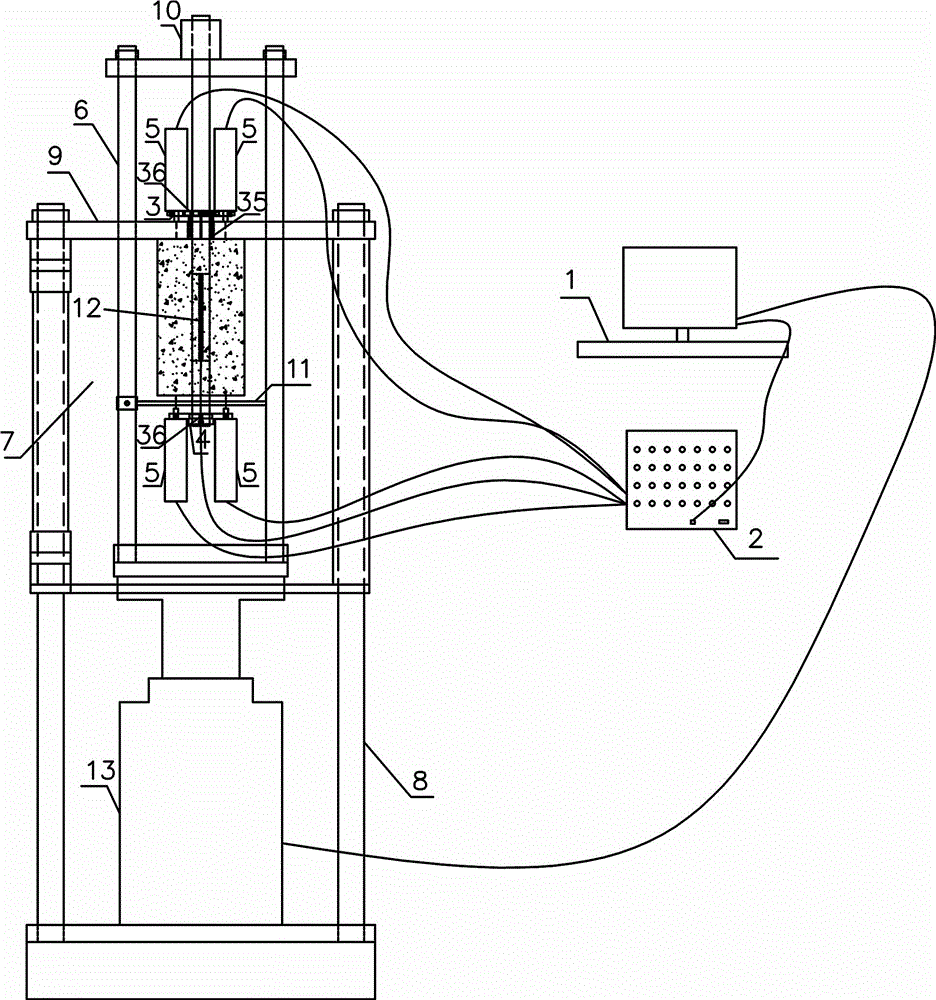

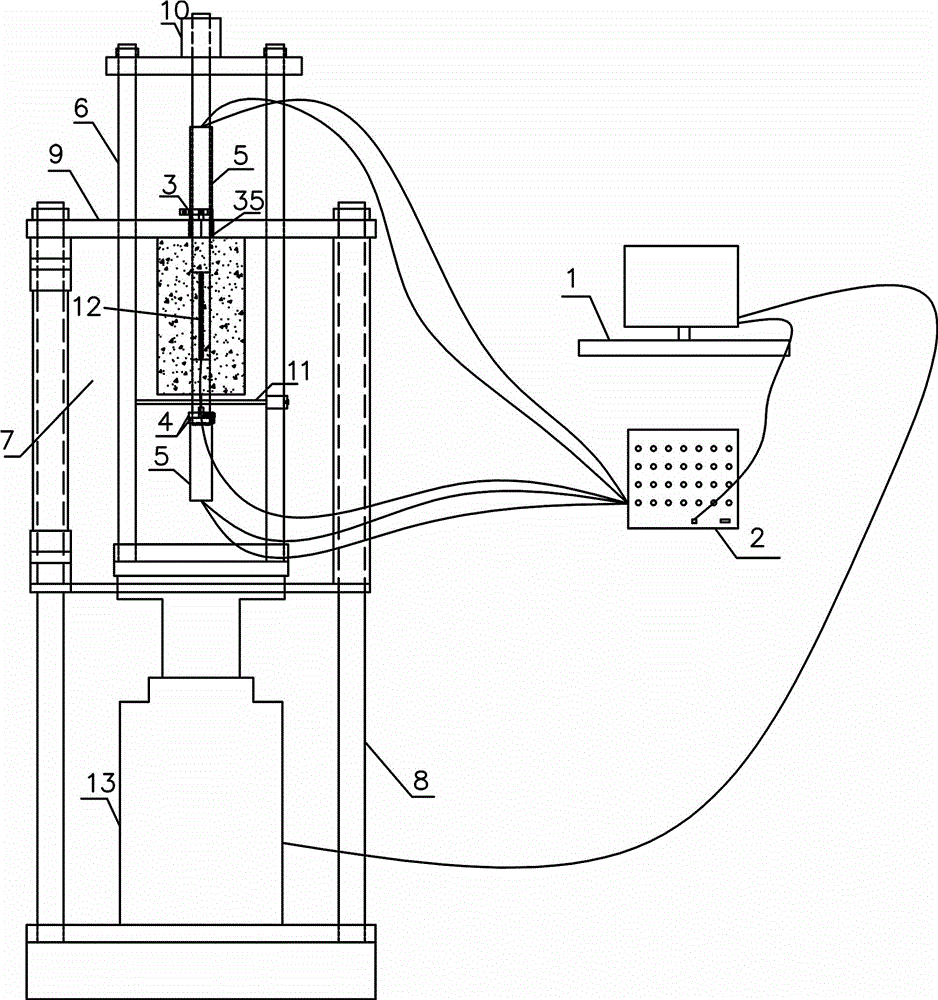

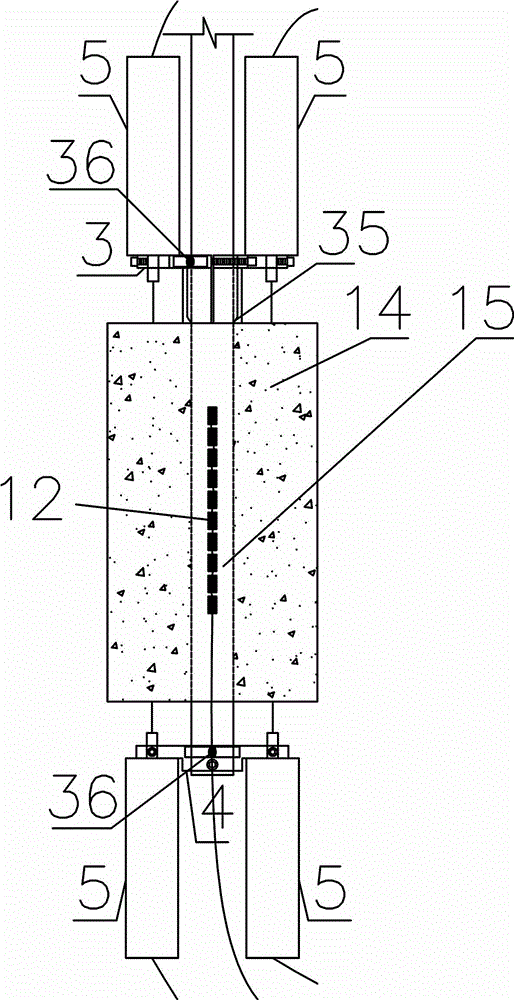

[0036] Such as figure 1 In ~7, a self-balancing reinforced concrete bond and anchor performance tester, the inner frame 6 is movably installed on the outer frame top plate 9 of the outer frame 8, the column of the inner frame 6 is slidingly connected with the outer frame top plate 9, and the inner frame 6 A loading device 13 is provided at the bottom, preferably, the loading device 13 is a hydraulic jack or a screw jack controlled by the computer 1 . In this way, the automatic setting of loading speed and loading force can be realized. The structures of the inner frame 6 and the outer frame 8 are relatively simple, easy to process, and do not need to be anchored, which simplifies the test conditions, and the structure is also convenient for loading the test piece, which simplifies the test steps and improves the test efficiency.

[0037] Such as figure 1 In 2, the steel bar 15 at the upper end of the test piece slides through the top plate of the outer frame top plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com