Assembly type micro-hole plate silencer

A technology of micro-orifice plate and muffler, which is applied in the direction of pipe components, mechanical equipment, pipes/pipe joints/pipe fittings, etc., can solve the problem of muffler products failing to play a role, and achieve small airflow resistance, avoid dust, and widen sound absorption. Band effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

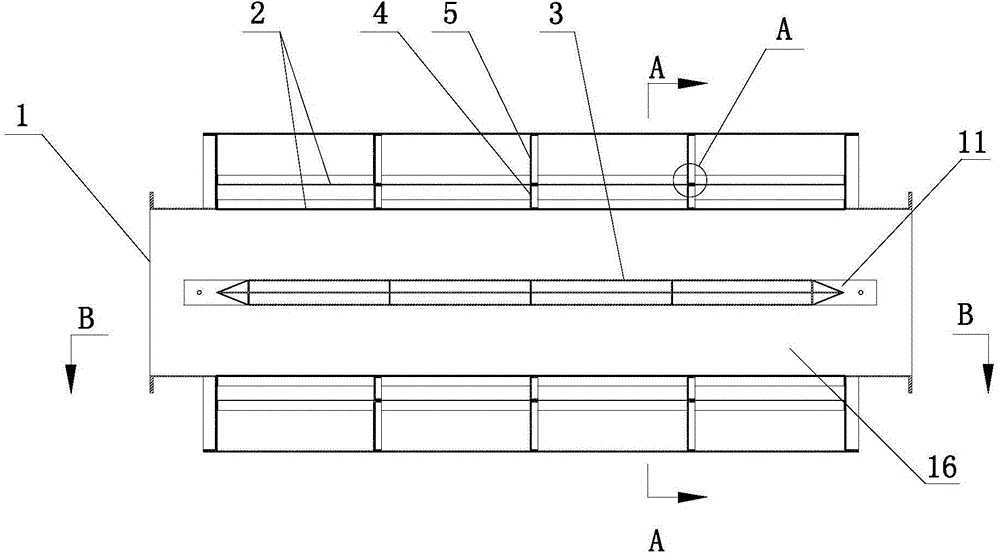

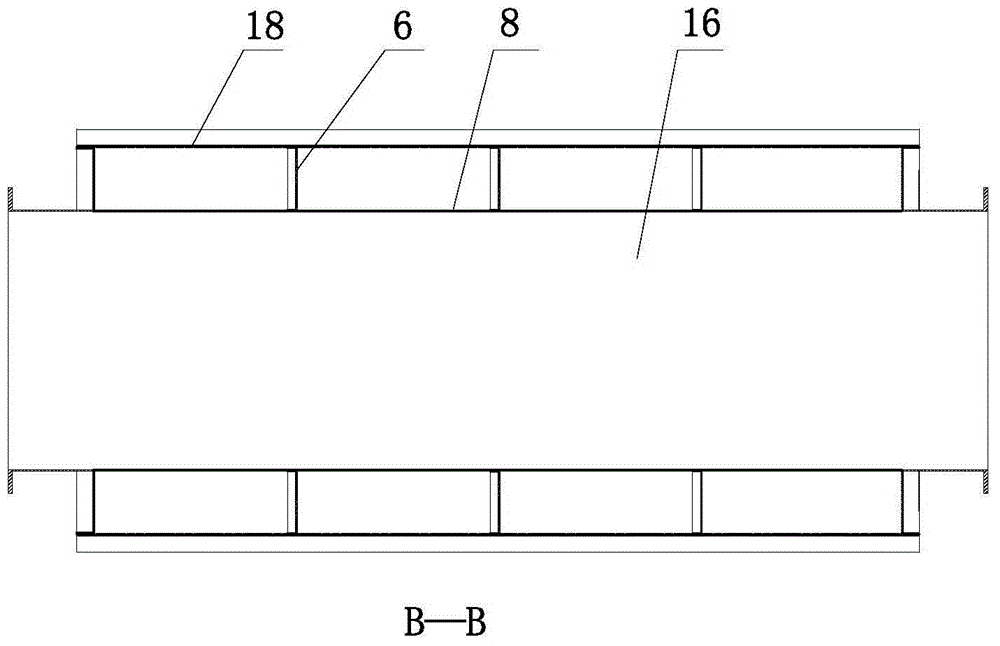

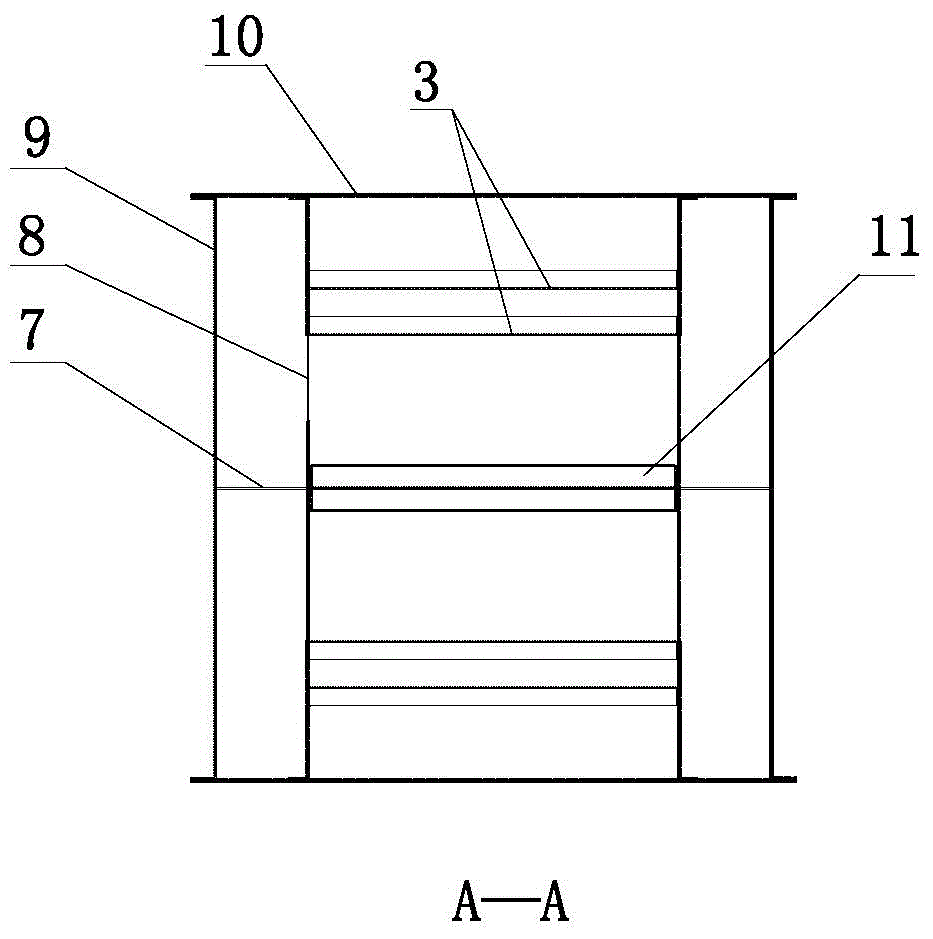

[0022] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0023] Such as figure 1 , figure 2 , image 3 and Figure 6 As shown, the assembled micro-orifice muffler of the present embodiment comprises a muffler main body of a rectangular tubular structure, and the two ends of the muffler main body are connected to the pipeline through a flange 1; Orifice sound-absorbing structure; the sound-absorbing sheet 7 is arranged along the central axis of the rectangular channel 8, including the first micro-orifice plate 6 located on the upper and lower sides, the middle steel plate 17, and multiple partitions arranged along the axis of the rectangular channel 8 14. The distance between the partitions is 250mm; the depth of the back cavity formed between the first microporous plate 6 and the steel plate 17 is 20mm, the micropore diameter of the first microporous plate 6 is 0.4mm, the plate thickness is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com