An inclined-axis telescope rack driving device

A technology for driving devices and telescopes, which is applied in the direction of telescopes, transmissions, gear transmissions, etc. It can solve the problems of staying in the concept stage and not forming, and achieve the effects of overall mass reduction, large support force, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

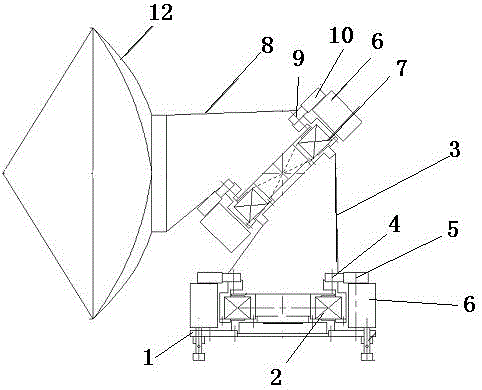

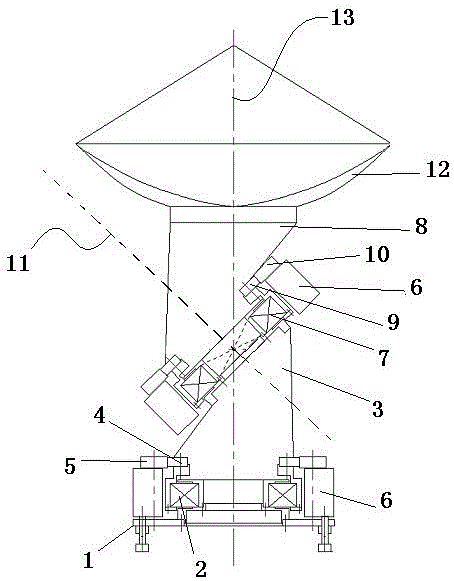

[0016] Such as figure 1 As shown, an oblique-axis telescope frame driving device includes a base 1, a first support mechanism 3, a second support mechanism 8, a first deep groove ball bearing 2, a second deep groove ball bearing 7, a first driven Gear 4, second driven gear 9 and antenna 12.

[0017] The above-mentioned first deep groove ball bearing 2 is arranged on the top surface of the base 1. The outer diameter of the first deep groove ball bearing 2 here is 200mm, and the first support mechanism 3 is an elliptical cylinder whose shape can be set according to the actual situation. The top surface of a support mechanism 3 is a slope, the bottom end of the first support mechanism 3 passes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com