Electric control engine speed adjustment characteristic curve design method

An electronically controlled engine and characteristic curve technology, applied in engine control, machine/engine, mechanical equipment, etc., can solve the problems of reduced life of engine parts, increased engine fuel consumption, high emissions, etc., to achieve the effect of increasing life and improving fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

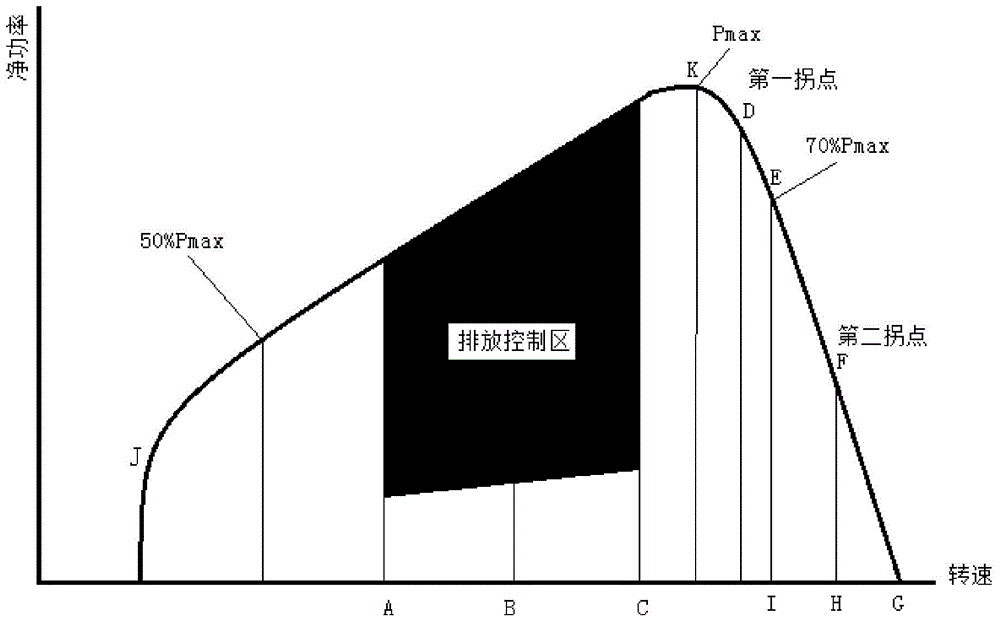

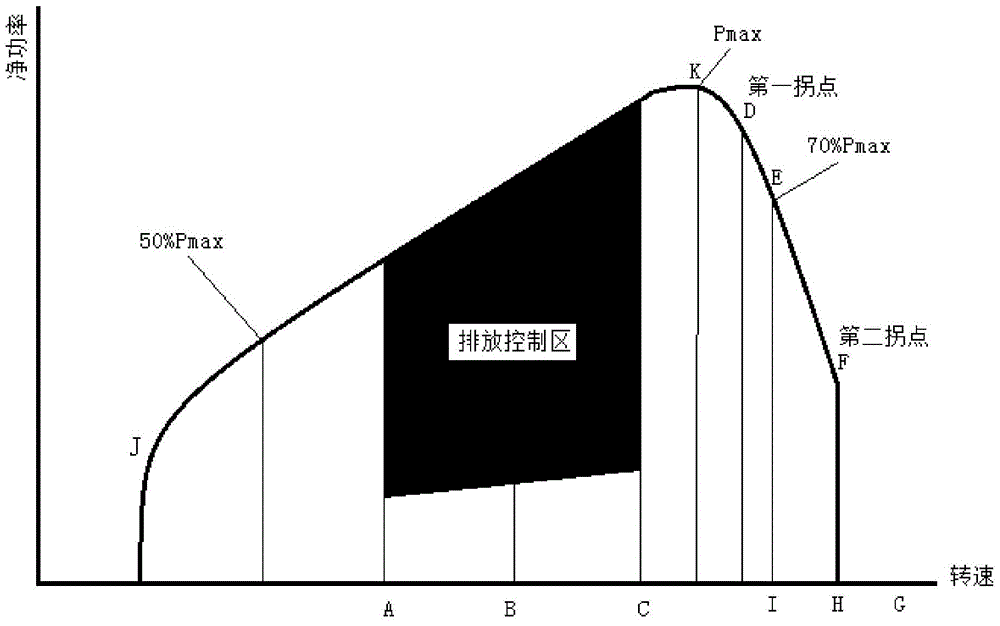

[0014] The existing speed regulation characteristic curve is as follows: figure 1 As shown, among them, the curve JKD is the external characteristic curve, the curve DG is the original speed regulation characteristic curve, and the K point is the rated power point. According to the requirements of the emission regulations GB 17691-2005, the speed at the point 50% Pmax is the maximum net power point K The speed at the point of 50% of the power, the speed of point E is the speed of 70% of the power of the maximum net power point K, the speed of point I is the same as the speed of point E, the speed of point B is 50% of Pmax and the midpoint of point I, point A is the midpoint of point 50% Pmax and point B, and point C is the midpoint of point B and point I. Point J is any point where the speed is less than 50% Pmax, point D is the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com