Dye continuous coupling method with reduced energy consumption

A technology of energy consumption and dyes, which is applied in the direction of azo dyes, organic dyes, monoazo dyes, etc., can solve the problems of low production efficiency and high energy consumption of freezing, so as to improve production efficiency, save cold energy, and reduce material transfer The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

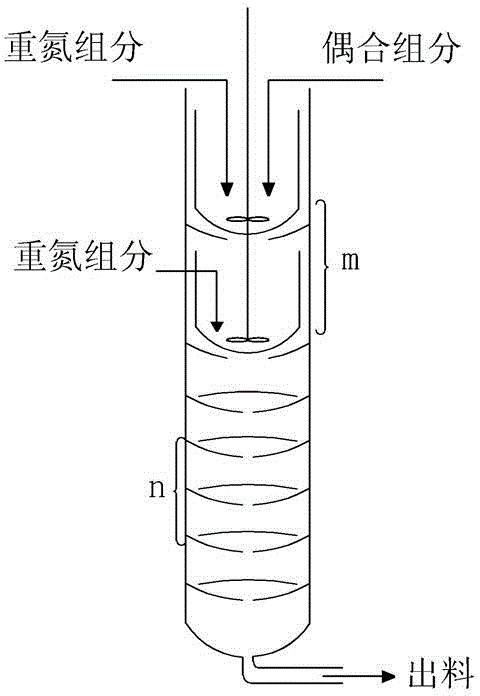

[0033] As shown in Figure 1, 926 kg of 3-acetylamino-N, N-diethylaniline, 10500 L of washing water cooled by a heat exchanger, and 5 kg of auxiliary agent TX-10 were beaten to obtain 8.1% coupling components Beating fluid.

[0034] Continuously pump the above-mentioned beating liquid into the tower-type first-section reactor at a flow rate of 3352kg / h, and at the same time inject 30% 2,4-dinitro-6 into the first-section coupling kettle at a flow rate of 1106kg / h - bromoaniline sulfate diazonium salt, control the reaction temperature of the first section of the coupling tank to 10-15 ° C, and carry out the coupling reaction under stirring. The output of the coupling reaction in the first section overflows to the secondary coupling kettle, and at the same time injects 30% 2,4-dinitro-6-bromoaniline diazonium sulfate into the second coupling kettle at a flow rate of 474kg / h , control the reaction temperature of the second coupling tank at 0-5°C, and carry out the coupling reacti...

Embodiment 2

[0037] Example 2 : 061#, diazo and coupling solution are added at one time, the yield is 98%

[0038] Such as figure 1 , beat 740kg of N-ethyl-N-cyanoethylaniline, 11500L of washing water cooled by heat exchanger, and 5kg of auxiliary agent TX-10 to obtain 6% coupling component beating liquid.

[0039] Continuously pump the above-mentioned beating liquid into the first section of the tower reactor at a flow rate of 3140kg / h, and at the same time inject 30% 2,6-dibromo-4-nitrate into the coupling kettle at a flow rate of 424kg / h Aniline sulfate diazonium salt, control the reaction temperature of the first coupling tank at 14-18°C, and carry out the coupling reaction under stirring. The output of the coupling reaction in the first section overflows to the secondary coupling kettle, and at the same time injects 30% 2,4-dinitro-6-bromoaniline diazonium sulfate into the second coupling kettle at a flow rate of 988kg / h , control the reaction temperature of the second coupling ta...

Embodiment 3

[0043] Such as figure 1 2-methoxy-5-acetylamino-N of 995kg, N-diacetoxyethylaniline, 12500L washing water cooled by heat exchanger 1, 5kg auxiliary agent TX-10 are beaten to obtain 7.4% coupling component beating fluid.

[0044] Continuously pump the above slurry into the first-stage coupling reactor at a flow rate of 3857kg / h, and at the same time inject 30% 2,4-dinitro-6-chloroaniline into the third-stage coupling reactor at a flow rate of 870kg / h Sulfate diazonium salt solution, carry out coupling reaction under stirring, control the molar ratio of diazonium salt and coupling component in the feeding material to be 1:1.01, wherein the diazonium solution is added in a ratio of 6:3:1 in 1- 3-stage coupling kettle. The output of the first-stage coupling reaction overflows to the second-stage coupling kettle, and the output of the second-stage coupling reactor overflows to the third-stage coupling kettle. Cool the first-stage coupling kettle with low-temperature water at 5°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com