Bimodal active alumina micropowder and preparation method

A technology of alumina micropowder and bimodal activity, which is applied in the field of refractory materials, can solve the problems of high production cost, concentrated particle size, and concentrated particle size of alumina powder, so as to improve the density and mechanical strength, increase the service life, and improve the performance Effect

Active Publication Date: 2015-08-12

浙江自立新材料股份有限公司

View PDF9 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the technical solutions disclosed in these two patents have high production costs, and the particle size of alumina powder is concentrated. They are mostly used in high-end ceramic products such as catalyst carriers, and are not suitable for use as a matrix for castables.

[0009] The alumina micropowders in the prior art are mostly unimodal distribution, with concentrated particle size and high production cost, which is not conducive to improving the performance of castables. Therefore, in view of the shortcomings of traditional activated alumina micropowders, it is necessary to develop bimodal (active) Aluminum oxide powder

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~8

[0036] (1) calcining industrial alumina powder at different temperatures to obtain calcined alumina powder with multiple primary crystal sizes;

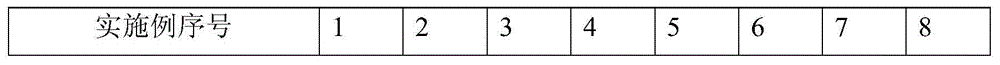

[0037] (2) Select two kinds of calcined alumina powders with different primary crystal sizes, and perform ball milling to obtain bimodal activated alumina micropowders. shown in Table 1.

[0038] Table 1

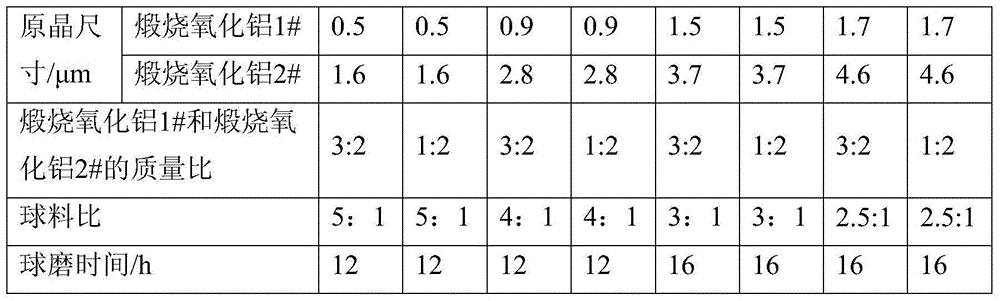

[0039]

[0040]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a preparation method for bimodal active alumina micropowder. The method comprises the following steps: (1) calcining industrial alumina powder at different temperatures so as to obtain calcined alumina powders with a variety of original crystalline sizes; (2) selecting two calcined alumina powders with different original crystalline sizes and carrying out ball milling so as to obtain the bimodal active alumina micropowder, wherein the mass ratio of the two calcined alumina powders with different original crystalline sizes is 0.2-5: 1. The preparation method for the bimodal active alumina micropowder provided by the invention is simple and can obtain bimodal-distribution active alumina micropowder; and the obtained bimodal alumina micropowder can be used for refractory products and can improve performances like construction performance, compactness, slag resistance and mechanical strength of the refractory products.

Description

technical field [0001] The invention relates to the field of refractory materials, in particular to a bimodal activated alumina micropowder and a preparation method thereof. Background technique [0002] Activated alumina powder is an extremely important refractory raw material, and its Al 2 O 3 The content is generally above 98%. Activated alumina micropowder is mostly made of industrial alumina as raw material, calcined at high temperature in a tunnel kiln (rotary kiln), and ground and classified. It has high purity, α-Al 2 O 3 It has the characteristics of high conversion rate, large true specific gravity, stable crystal form, narrow particle size distribution and good dispersibility. , epoxy resin casting filler, grinding, polishing abrasives, etc. [0003] As an important part of the matrix material in the refractory castable, activated calcined alumina micropowder has irreplaceable functions such as high temperature resistance and sintering promotion. The particl...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B35/10C04B35/626

Inventor 宋雅楠赵义黄凯马铮沈明科方斌祥薛军柱

Owner 浙江自立新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com