Automatic forward-backward flushing membrane filtering water-cleaning system

A technology of positive and negative flushing and water purification systems, applied in ultrafiltration, membrane technology, semi-permeable membrane separation, etc., can solve problems such as incomplete flushing, reduced membrane life, lack of filter membrane positive flushing process, etc., to improve filtration Effects of water flux, increased service life, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, the present invention will be described in detail with reference to the drawings and the embodiments. The embodiments described below with reference to the accompanying drawings are exemplary, and are intended to explain the present invention, but should not be construed as limiting the present invention.

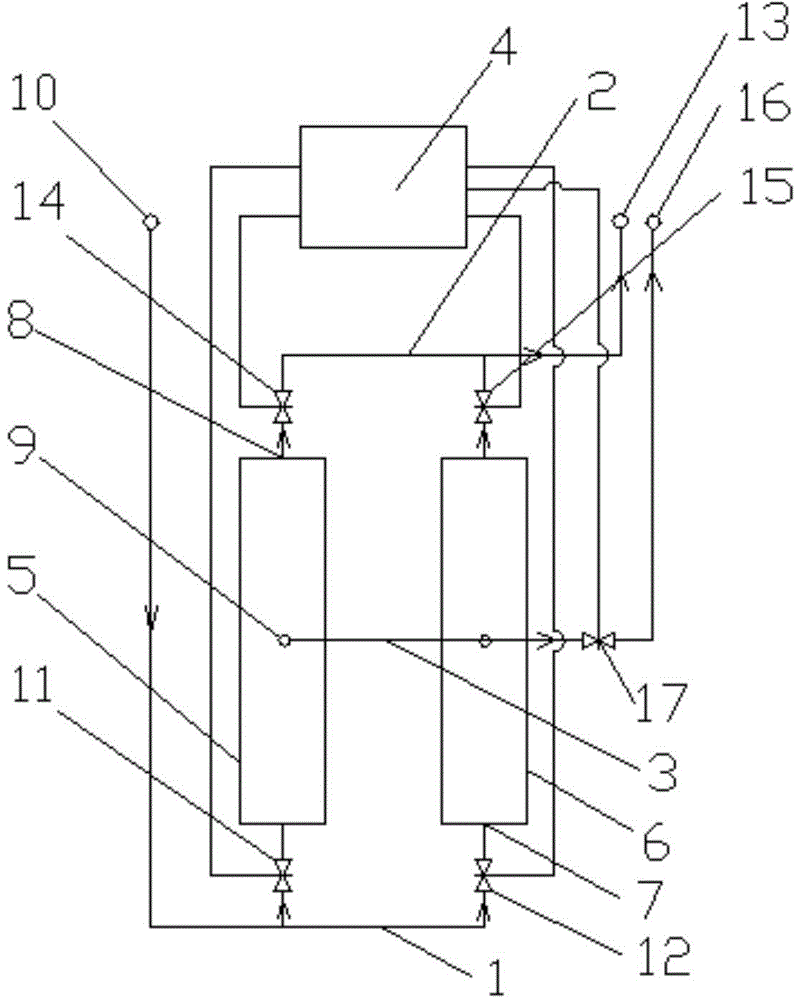

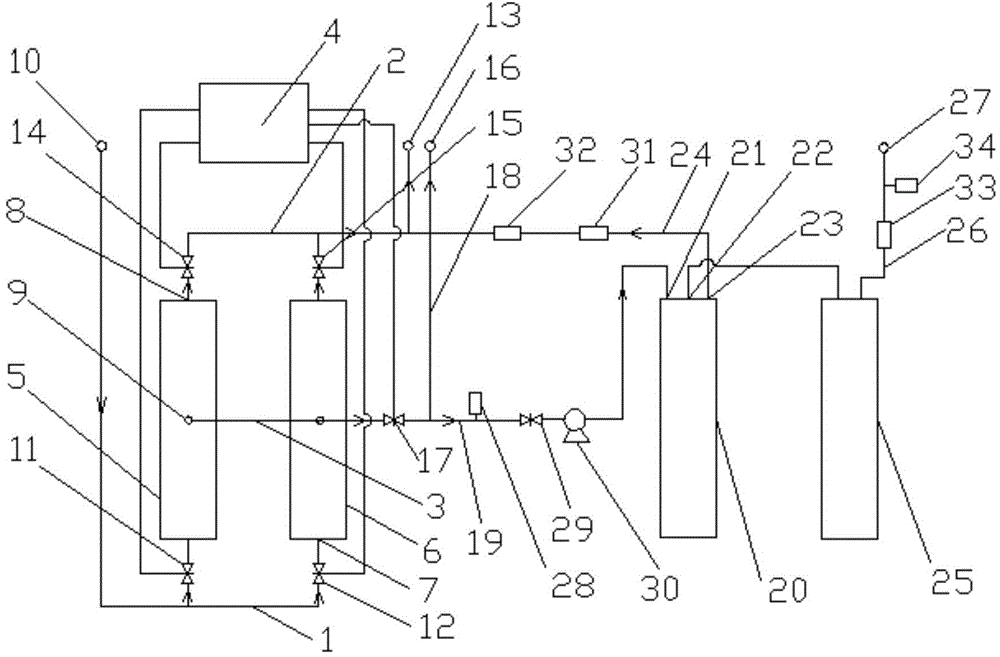

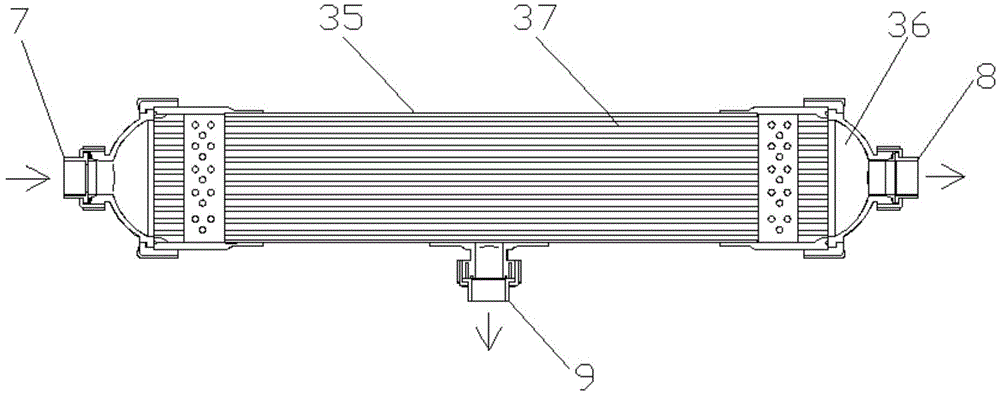

[0042] Such as figure 1 The automatic positive and negative flushing ultrafiltration water purification system shown includes the inlet pipe 1, the sewage pipe 2, the outlet pipe 3, the control system 4 and two identical internal pressure hollow fiber ultrafiltration membrane modules, which are internal The pressure type hollow fiber ultrafiltration membrane module A 5 and the internal pressure type hollow fiber ultrafiltration membrane module B 6 are respectively provided with a water inlet 7 and a water outlet 8 at both ends of the internal pressure type hollow fiber ultrafiltration membrane module. The inner pressure type hollow fiber ultrafiltration mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com