Hydrogen chloride synthesizer capable of generating coproduct high pressure steam and synthesis process of synthesizer

A high-pressure steam, synthesis device technology, applied in chlorine/hydrogen chloride, steam generation, steam generation methods, etc., can solve the problems of no anti-corrosion and anti-seismic treatment, unpublished data range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

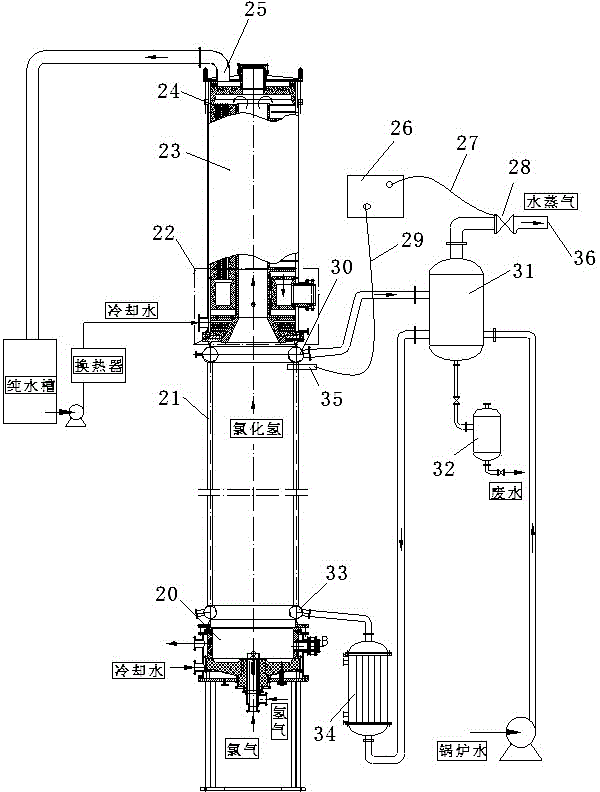

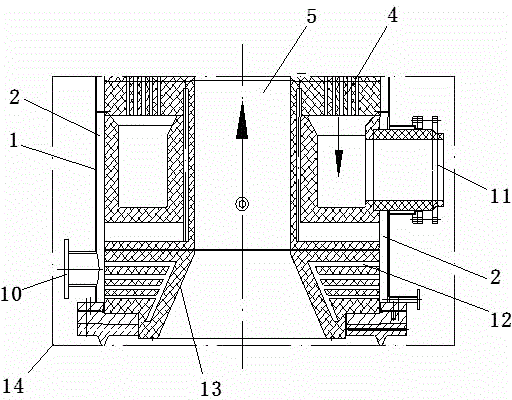

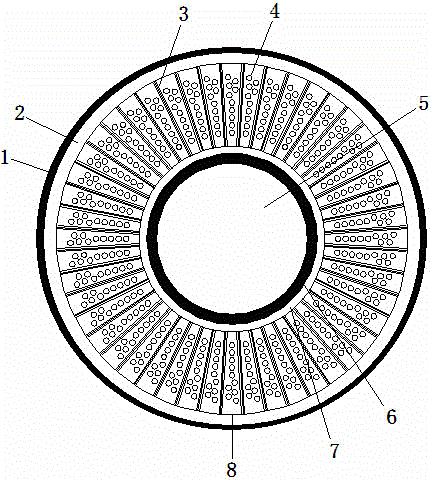

[0040] likefigure 1 , 2 , the hydrogen chloride synthesis device of by-product high-pressure steam shown in 3 has synthesis furnace, flash tank, preheater, and synthesis furnace is made up of the graphite synthesis section of furnace bottom, the steel steam generation section of middle part and the cooling section of top, The hydrogen chloride outlet is located below the cooling section; among them, the steel steam generation section adopts thick-walled steel pipes with an outer diameter of 80mm and flat steel interlaced welded to form a closed cylindrical wall for the synthesis gas to pass through, and the steel pipes on the wall Provide water vapor to pass through and cool down the synthesis gas and absorb the heat of reaction;

[0041] The cooling section is composed of a steel shell, a graphite cylinder in the middle and a steel inner shell. The central axial hole surrounded by the steel inner shell is used for the rising hydrogen sulfide to flow. Numerous axial gas chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com