A charging barrel used for mixing dry powder and mortar

A dry powder mortar and barrel technology, which is applied in clay preparation devices, chemical instruments and methods, cement mixing devices, etc., can solve the problems of high energy consumption, reduce the production efficiency of dry powder mortar, and cannot be continuously mixed, and can increase the falling time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

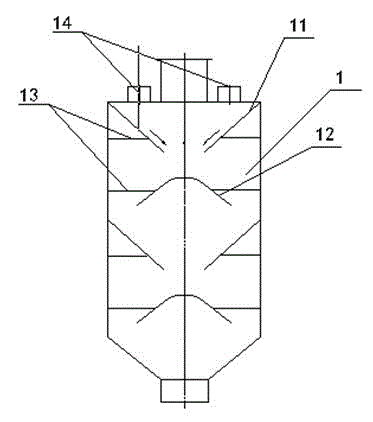

[0017] The barrel for mixing dry powder mortar provided in this embodiment is mainly composed of a barrel body 1 and a blanking partition. The blanking partition is set on the inner wall of the cylinder, see figure 1 .

[0018] Four feeding ports 14 are respectively arranged above the barrel. There is a discharge port at the bottom of the barrel. The barrel 1 shrinks relative to the barrel wall at the outlet to form a bucket shape. The four feeding ports 14 of the barrel are respectively connected with four kinds of materials: dry sand, cement, fly ash, and thickened powder. The various materials are affected by gravity, fall naturally, pass through the blanking partition in turn, and finally come out of the bottom of the barrel. Discharge from the outlet.

[0019] Blanking dividing plate is made up of two kinds of dividing plates of some peak-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com