A high-precision two-petal flat chuck device

A high-precision, collet technology, used in clamping devices, positioning devices, clamping and other directions, can solve the problems of poor symmetry, poor stability, limited processing space, etc., to achieve good symmetry, high stability, center high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Further description will be given below for the embodiments of the present invention:

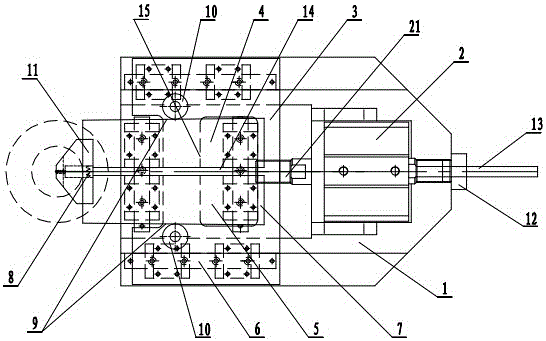

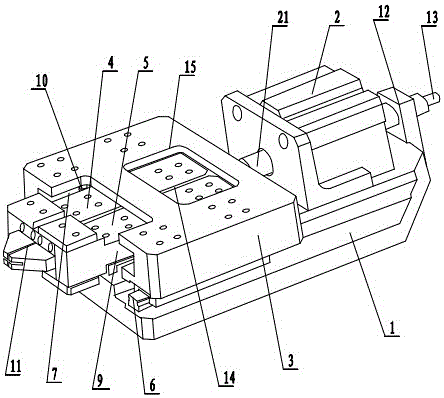

[0012] As shown in the figure, a high-precision two-petal flat chuck device includes a base 1, a cylinder 2, a slide plate 3, a first splint 4 and a second splint 5, the piston rod 21 of the cylinder 2 is connected to the slide plate 3, Both sides of the base 1 are provided with precision slide rails 6, and both sides of the slide plate 3 are slidingly matched with the precision slide rails 6 respectively. The middle part of the slide plate 3 is provided with an accommodating groove 7, and the first The splint 4 and the second splint 5 are symmetrically distributed in the accommodating groove 7 along the center of the slide plate 3, and a spring 8 is arranged between the first splint 4 and the second splint 5, and the first splint 4 and the second splint The side of the splint 5 is an inclined surface 9, and the two sides of the slide plate 3 are provided with rollers 10, and the rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com