Washing and regenerating method of particle filter material filter tank for preventing filter material from scaling and hardening

A granular filter material and filter tank technology, applied in the direction of loose filter material filter, filter separation, separation method, etc., can solve the problem of chemical cleaning and replacement of filter material polluting the environment, frequent backwashing, high energy consumption, and backwashing return flow Large and other problems, to achieve the effect of preventing scaling and hardening, simple and easy operation, and thorough backwashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

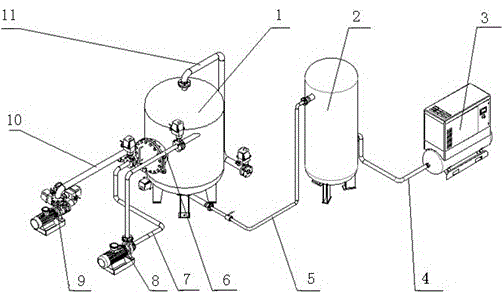

[0016] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

[0017] A method for washing and regenerating a filter tank of granular filter material to prevent scaling and hardening of the filter material, comprising the following steps:

[0018] (1) Start the air compressor 3 to compress the air in the air storage tank 2 through the air storage tank intake pipeline 4 before the filter tank 1 is shut down, and the air storage pressure must be greater than the filter operating pressure;

[0019] (2) After the filter tank 1 is out of service, connect the backwash blowdown pipe valve 11 to relieve the pressure of the filter tank 1, and release the pressure in the filter tank 1 to normal pressure, so as to increase the gas explosion pressure difference and improve the gas explosion effect;

[0020] (3) After the filter tank 1 is released to normal pressure, quickly connect the gas explosion pipe valve 5 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com