Filter lens holding mechanism for filter frame

A technology for holding mechanisms and lenses, which is applied to photographic filters, camera bodies, and optics. It can solve the problems of reduced effective diameter, severe lens surface deformation, and thermal deformation of the lens to achieve weight reduction and lightening. burden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

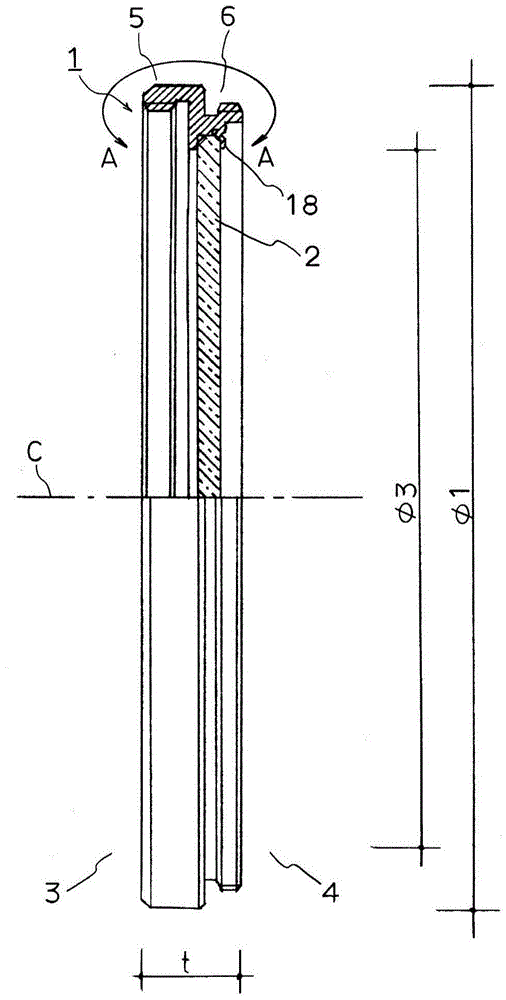

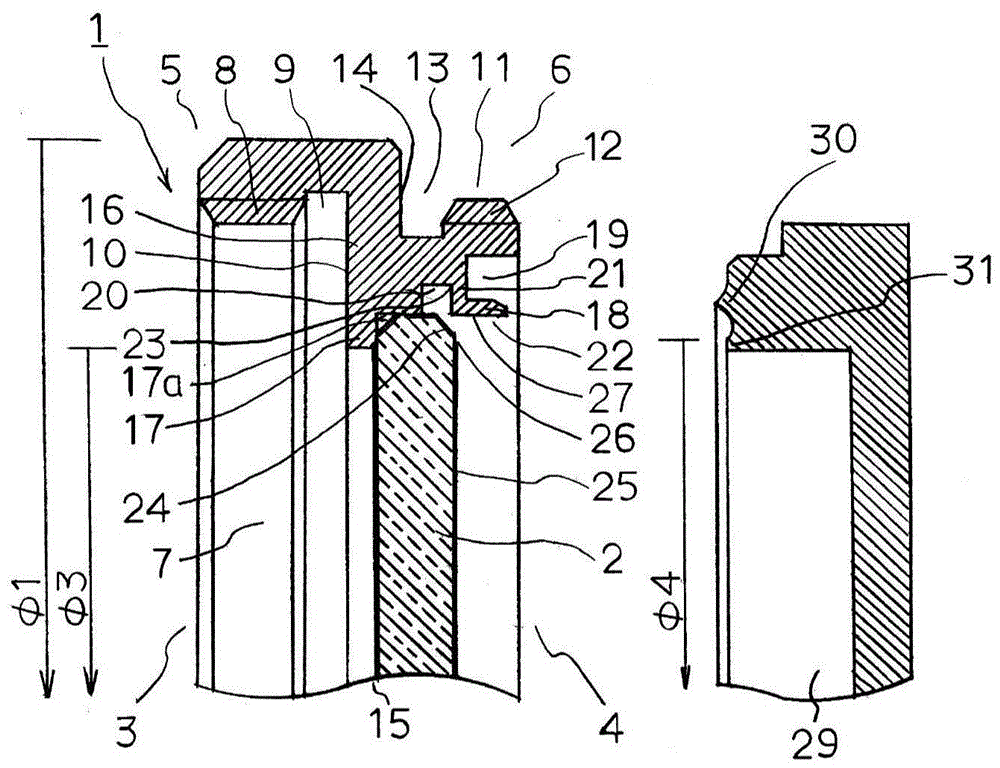

[0154] figure 1 This is a cross-sectional view illustrating the main part of a filter frame according to Embodiment 1 of the present invention, which is mounted on the front surface of a lens barrel of a digital camera for use. Figure 2A for figure 1 The enlarged cross-sectional view of part A-A of , Figure 2B is in Figure 2A The cross-sectional view of is an explanatory diagram showing the state of riveting completion.

[0155] exist figure 1 Among them, 1 represents the main body of the filter frame, 2 represents the filter lens, with the main body 1 of the filter frame as the center, 3 represents the incident light side, 4 represents the lens barrel side, and C represents the optical axis of the main body of the filter frame. In addition, in figure 1Among them, t represents the thickness of the main body of the filter frame, φ1 represents the aperture of the filter, and φ3 represents the effective diameter of the filter lens.

[0156] In addition, the filter lens 2...

Embodiment 2

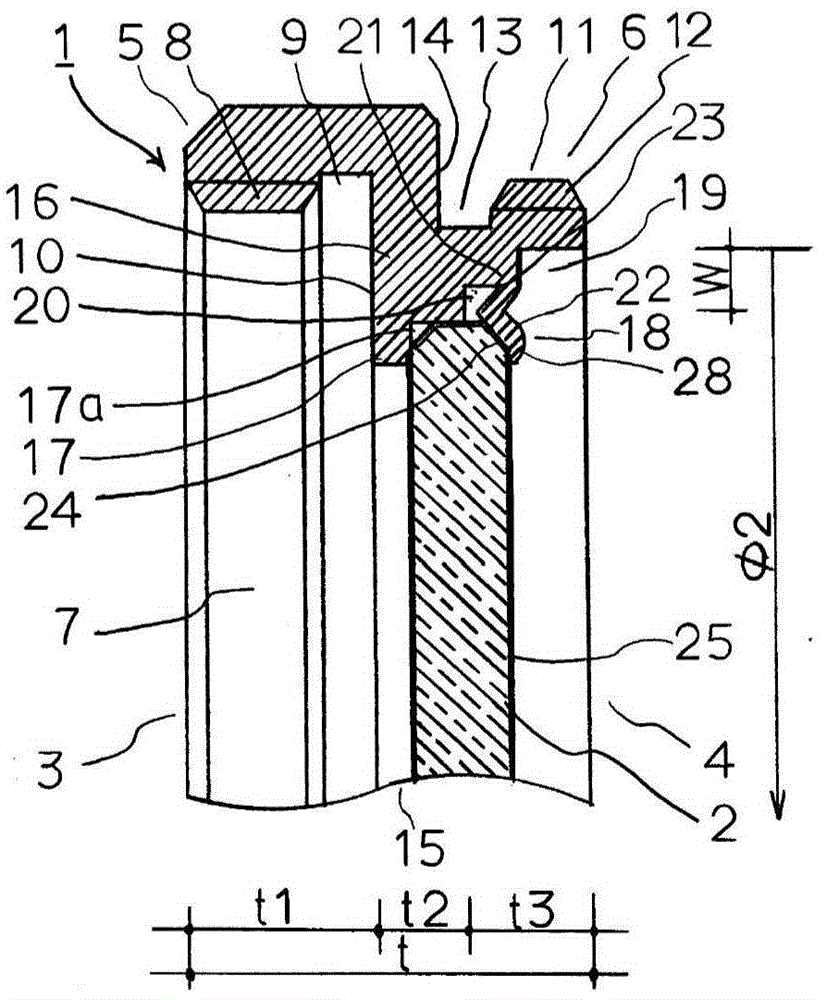

[0173] Figure 3A , Figure 3B Embodiment 2 of the present invention will be described, and the same reference numerals as those in FIG. 2 denote the same characteristic elements. exist Figure 3A , Figure 3B Among them, 1 is the main body of the filter frame, which is manufactured by notching an annular ring made of metal such as aluminum or brass. In addition, 2 represents the filter lens, t represents the thickness of the filter frame body 1, 3 represents the incident light side of the filter frame body, and 4 represents the lens barrel side of the filter frame body, and the filter frame body 1 is integrated Formed, and the filter frame main body 1 is roughly divided into two parts, the part on the incident light side 3 is used as the front tube frame 5, and the part on the lens barrel side 4 is used as the rear tube frame 6.

[0174] The inner diameter portion 7 of the front tube frame 5 of the filter frame main body 1 is provided with an internal thread portion 8 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com