A method for detecting the output accuracy of a resolver for a motor

A resolver and detection method technology, which is applied in the field of detecting the resolver output and angle error to compensate its accuracy, and can solve the problems of vehicle operation safety hazards, increased iron consumption, and difficulty in controlling the accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with the examples, the specific implementation of the present invention will be further described in detail. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

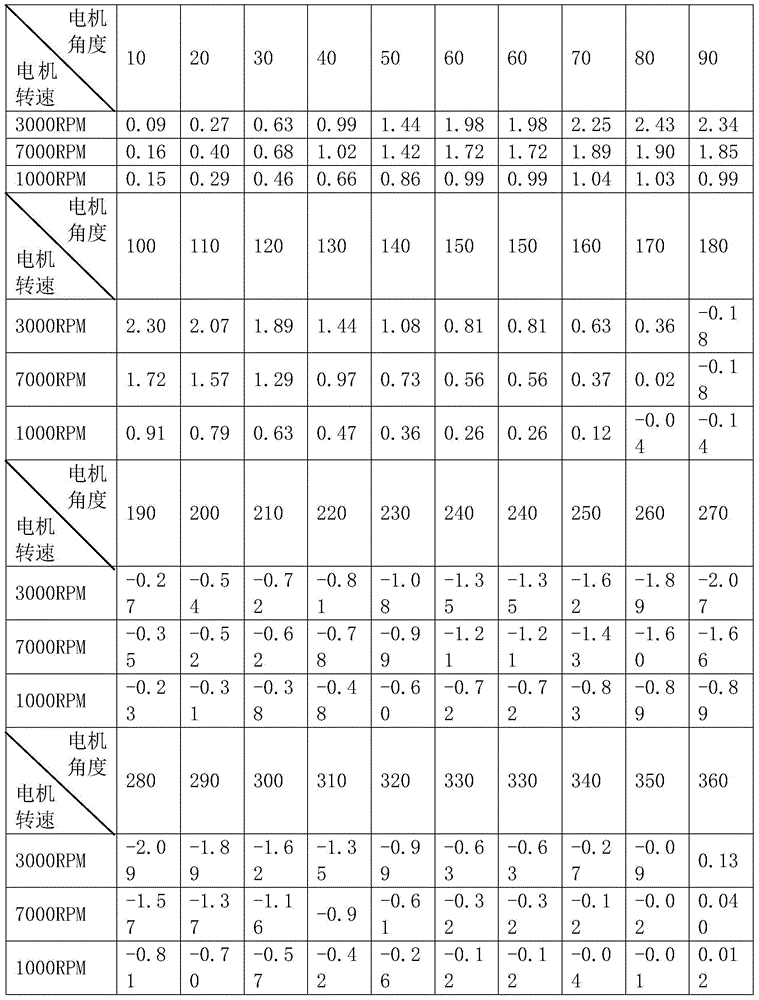

[0013] According to a preferred embodiment of the present invention, a method for detecting the output accuracy of a resolver for a motor, the output end of the resolver is connected to a detection unit, the detection unit includes a first decoding unit and a second decoding unit, and the first decoding unit The bandwidth of the unit is smaller than the bandwidth of the second decoding unit. The first decoding unit is used to detect the output angle of the motor when the motor is running at high speed, and the second decoding unit is used to detect the corresponding output angle of the motor at different speeds of the motor. That is, the high-precision 1. The first decoding unit with low bandwidth can attenu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com