A geared motor

A technology of geared motors and main motors, which is applied to gear transmission mechanisms, electromechanical devices, electrical components, etc., which can solve problems such as limited speed regulation range, error-prone, and complicated use, and achieve the effect of eliminating mechanisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

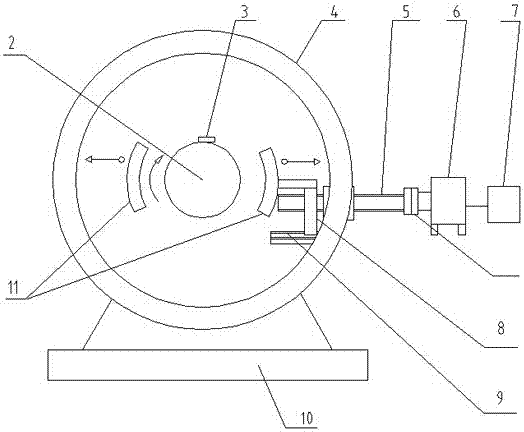

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0012] As shown in the figure, a geared motor includes a main motor, and the main motor is provided with a main motor base 10 .

[0013] It also includes a braking device, which includes an arc-shaped brake pad 1, a slide block 8 fixedly connected with the arc-shaped brake pad 1, a lead screw 5 threaded with the slide block 8, and a control lead screw 5 rotating stepper motor 6 and a control device 7 for controlling the action of the stepper motor 6, the concave surface of the arc-shaped brake pad 1 is set towards the output shaft 2 of the main motor, and the convex surface of the arc-shaped brake pad 1 is fixedly connected to the Slider 8 described above.

[0014] Also be provided with a circular brake frame 4, the brake frame can be fixed on the main motor base 10.

[0015] The brake frame 4 is fixed with a slide rail 9, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com