Double-station annular heat supply network

A heating pipe network and heating pipe technology, which is applied in household heating, heating systems, space heating and ventilation, etc., can solve problems such as heating temperature imbalance, achieve temperature imbalance, improve water temperature Pressure, the effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below with reference to the drawings and specific embodiments.

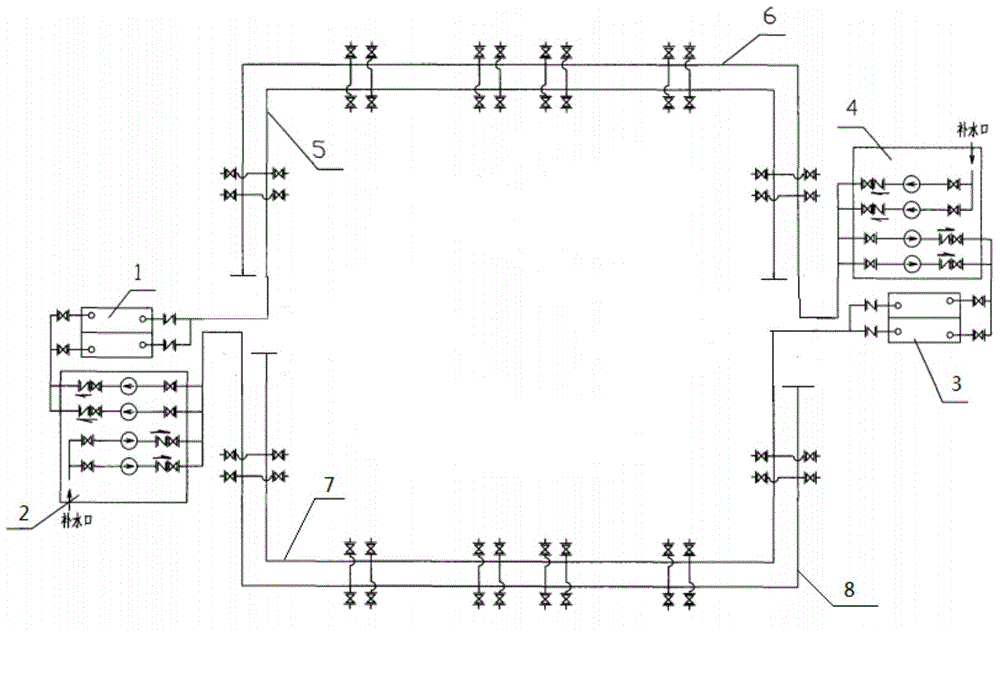

[0015] A kind of double-station ring heating pipe network, such as figure 1 Shown. Including two sets of vacuum hot water boilers and their matching pressurization cycle equipment, vacuum hot water boiler a1 and pressurization cycle equipment a2, vacuum hot water boiler b3 and pressurization cycle equipment b4 form a dual station, the vacuum hot water boiler a1 The water outlet is connected to one end of the outlet pipe of the heating pipe a5, the other end of the outlet pipe of the heating pipe a5 is blocked, the return port of the pressurized circulation device b4 is connected to one end of the return pipe of the heating pipe b6, and the return pipe of the heating pipe b6 The other end is blocked, the outlet of the vacuum hot water boiler b3 is connected to one end of the outlet pipe of the heating pipe c7, the other end of the outlet pipe of the heating pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com