A method for preventing viton o-ring from sticking during secondary vulcanization

A secondary vulcanization and O-ring technology, which is applied to the surface coating liquid device, pretreatment surface, coating, etc., can solve problems such as sticking, achieve good consistency of installation torque, simple operation, and reduce The effect of missed detection risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preventing the viton O-ring from sticking during secondary vulcanization of the present embodiment, the steps are:

[0035] A. Cleaning: Add 10,000 pieces of fluorine rubber O-rings to a 20L drum cleaning machine. The specifications of the O-rings are: outer diameter 17.9mm, wire diameter 1.6mm; add 20 grams of industrial detergent to the drum; rotate the drum to clean After 9 minutes, drain the cleaning solution and rinse it again with clean water; dry the cleaned product at 90°C for 5 minutes;

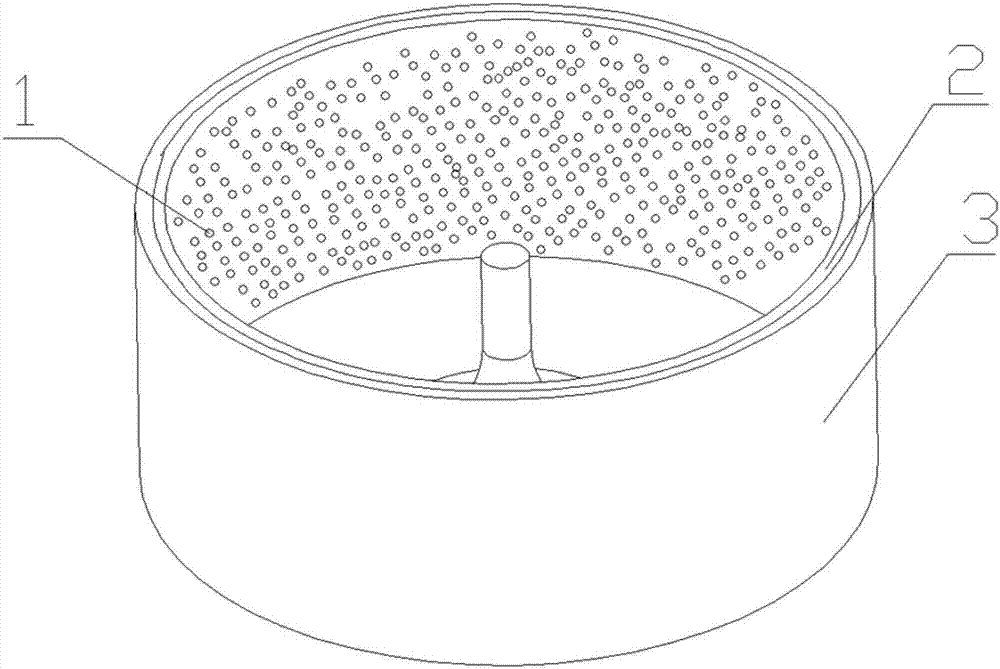

[0036] B. Feeding: Put the cleaned and dried O-ring into a 25L tumble dryer, and lay the product flat by hand;

[0037] C. Spray release agent: Spray the diluted emulsified silicone oil on the surface of the O-ring with a watering can with a scale. The spray amount of the emulsified silicone oil is 7ml; during the spraying process, ensure that the emulsified silicone oil sprayed from the watering can becomes mist (the grade of silicone oil is selected as IE349, t...

Embodiment 2

[0044] A method for preventing the viton O-ring from sticking during secondary vulcanization of the present embodiment, the steps are:

[0045] A. Cleaning: Add 12,000 pieces of fluorine rubber O-rings to a 20L drum cleaning machine. The specifications of the O-rings are: outer diameter 13.5mm, wire diameter 1.8mm; add 25 grams of industrial detergent to the drum; rotate the drum to clean After 8 minutes, drain the cleaning solution and rinse it again with clean water; dry the cleaned product at 80°C for 6 minutes;

[0046] B. Feeding: put the cleaned and dried O-ring into a 25L tumble dryer, and pave the product by hand;

[0047] C. Spray release agent: Spray the diluted emulsified silicone oil on the surface of the O-ring with a watering can with a scale. The spraying amount of the emulsified silicone oil is 8ml; during the spraying process, ensure that the emulsified silicone oil sprayed from the watering can becomes mist (the grade of silicone oil is selected as IE349, the ...

Embodiment 3

[0054] A method for preventing the viton O-ring from sticking during secondary vulcanization of the present embodiment, the steps are:

[0055] A. Cleaning: Add 12,000 pieces of fluorine rubber O-rings to a 20L drum cleaning machine. The specifications of the O-rings are: outer diameter 15.5mm, wire diameter 1.7mm; add 25 grams of industrial detergent to the drum; rotate the drum to clean After 10 minutes, drain the cleaning solution and rinse it again with clean water; dry the cleaned product at 100°C for 5 minutes;

[0056] B. Feeding: put the cleaned and dried O-ring into a 25L tumble dryer, and pave the product by hand;

[0057] C. Spray release agent: Spray the diluted emulsified silicone oil on the surface of the O-ring with a watering can with a scale. The spraying amount of the emulsified silicone oil is 6ml; during the spraying process, ensure that the emulsified silicone oil sprayed from the watering can becomes mist (the grade of silicone oil is selected as IE349, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com