A labyrinth type supergravity liquid-liquid extraction separator

A super-gravity, labyrinth technology, applied in the field of enhanced mass transfer, can solve the problems of small centrifugal force and small liquid handling capacity, and achieve the effects of prolonging the reaction time, increasing the mass transfer area, and improving the extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

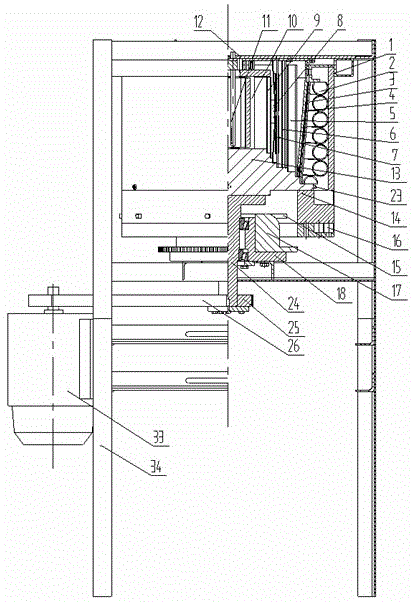

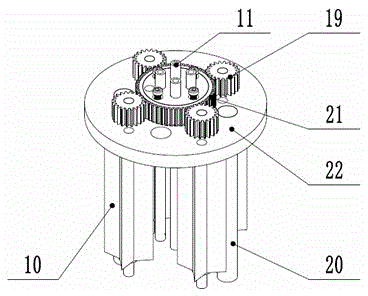

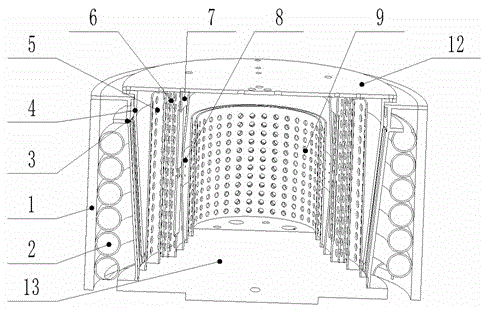

[0035] Example 1: Such as Figure 1-14 As shown, the labyrinth-type supergravity liquid-liquid extraction separator includes a housing 1, a filler spiral tube 2, a mixing mass transfer mechanism, a separation and collection mechanism, a top cover plate 12, a base 13, a bearing housing 18, a shaft 24, and a motor 33; The top cover plate 12 is fixed on the upper end of the housing 1 by screw connection, the base 13 is arranged in the cavity of the housing 1 and its lower end is fixedly connected to the shaft 24, the mixing mass transfer mechanism is arranged on the base 13, and the separation and collection mechanism is arranged on the lower end of the base 13 and Connected to the lower end of the housing 1, the filler spiral tube 2 is fixed inside the housing 1, the bearing housing sleeve 18 and the rotary switch 17 are threaded auxiliary, the bearing housing sleeve 18 is sleeved on the shaft 24, and the bearing housing sleeve 18 is fixed on the machine by screw connection On th...

Embodiment 2

[0041] Embodiment 2: The device structure of this embodiment is the same as that of Embodiment 1, except that two pairs of small impellers are added to increase the shell radius of the filler spiral tube, and other conditions remain unchanged.

Embodiment 3

[0042] Embodiment 3: The device structure of this embodiment is the same as that of Embodiment 1. The number of rings of the moving disk packing layer and the static disk packing layer in the mass transfer device is increased, the shell radius of the packing spiral tube is increased, and other conditions remain unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com