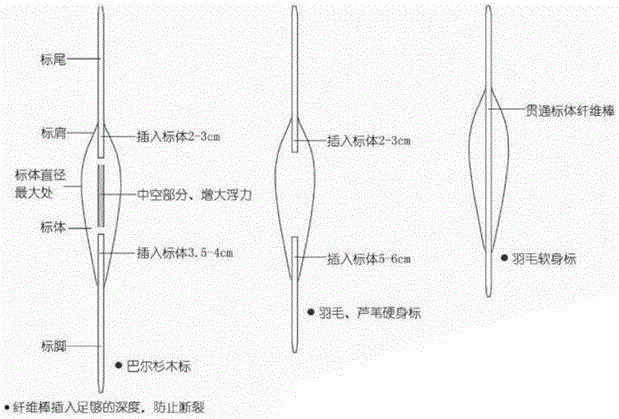

Carbon fiber buoy and production technology thereof

A production process, carbon fiber technology, applied in fishing accessories, fishing, applications, etc., can solve the problems of insufficient strength, easy to break, etc., and achieve the effect of being conducive to environmental protection and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Embodiment 1: the preparation of buoy

[0070] 1. Making PU inner core:

[0071] 1. Mix the PU black and white material according to the weight ratio of 1:1, stir evenly, pour it into the mold cavity, and the molding time is 6 minutes; the molding temperature is 80°C, and the first PU inner core is obtained;

[0072] 2. Take out the obtained first PU inner core from the mold, and pull out the thimble in the PU inner core;

[0073] 3. Use 600# sandpaper to roughen the surface of the first PU inner core, that is, to grind the surface of the PU inner core evenly, and clean the surface; see figure 2 shown.

[0074] 4. Evenly coat epoxy resin on the surface of the first PU inner core. The thickness of the coating must be controlled within 0.01MM. You can use a scraper to scrape off the excess resin on the surface of the PU inner core, and then let it stand at room temperature for 12 hours. That is to get the second PU inner core. Let the resin react naturally at room tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com