Method for determining stretch flange limit strain and method for assessing press forming feasibility

A technology of ultimate strain and stretch flange, which is applied in the field of determining the limit strain of stretch flange and whether it can be stamped and formed, and can solve the problems of different deformation methods of the plate edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

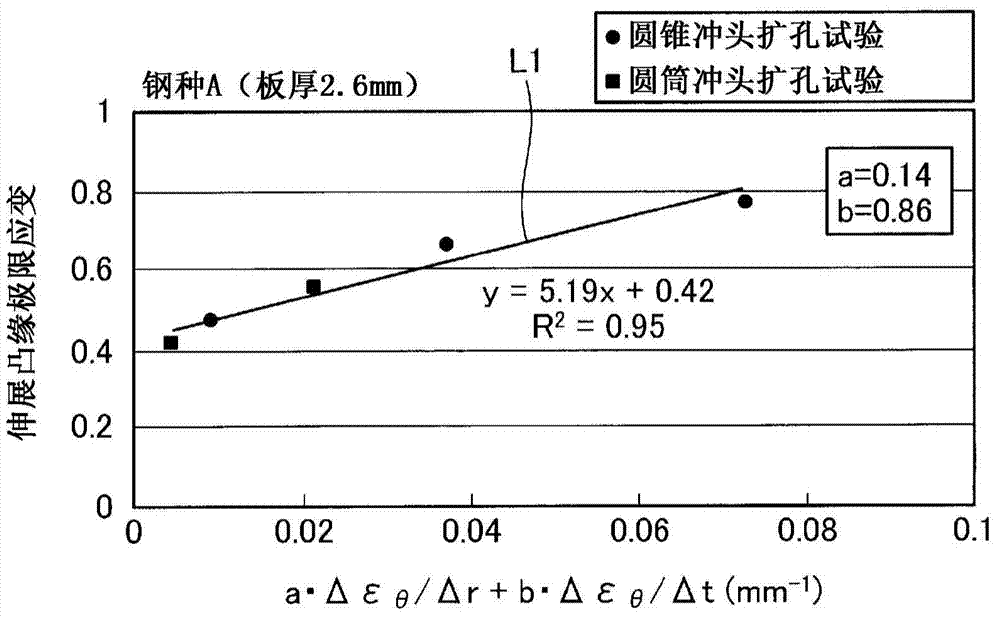

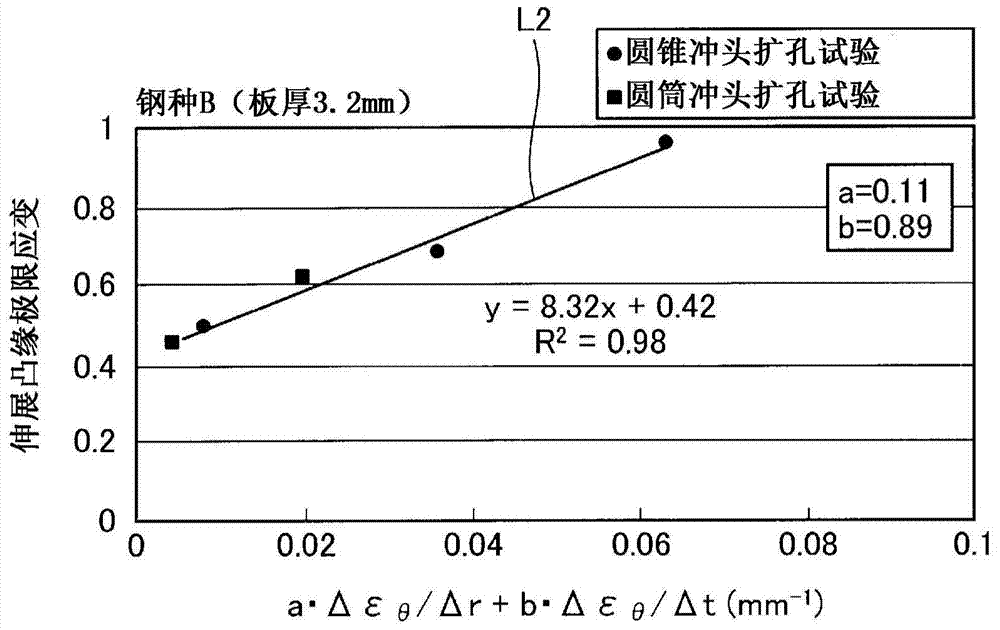

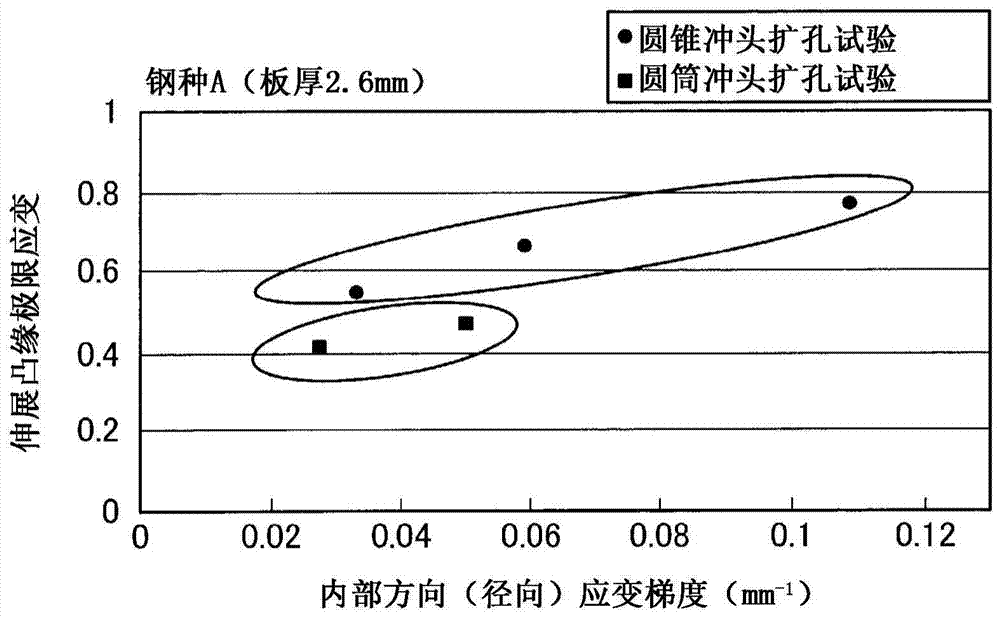

[0051] The method for determining the limit strain of the stretch flange according to the present invention is characterized in that the strain gradient in the direction from the end of the metal plate toward the inside when the load is applied (in the case of a hole expansion test, the radial strain gradient) and the load The strain gradient in the plate thickness direction of the metal plates whose directions intersect are determined so as to satisfy the relationship of the following formula (1).

[0052] ε θlim =A〔a·Δε θ / Δr+b·Δε θ / Δt〕+c···(1)

[0053] Among them, in formula (1), ε θ is the circumferential strain at the edge of the hole (stretch flange strain), ε θlim is the ultimate strain of the stretched flange, Δε θ / Δr is the strain gradient in the internal direction (radial strain gradient), Δε θ / Δt is the strain gradient in the plate thickness direction, A, a, and b are the influence coefficients, and c is the ultimate strain when the strain gradient is 0 (ze...

Embodiment approach 2

[0096] In Embodiment 1 above, the case where both the strain gradient in the internal direction (radial direction) and the strain gradient in the plate thickness direction were considered was described, however, experiments were conducted based on the following assumptions: whether only the plate A strain gradient in the thickness direction is sufficient, so the results will be described below.

[0097] In the experiment, metal plates (plate thickness 2.6 mm) composed of three steel types (steel type C to steel type E) with different compositions and structures were punched using a conical punch and a cylinder in the same manner as in Embodiment 1. Conduct hole expansion test. The size of the hole before the test was set to 10φ, 20φ, 25φ, and 50φ.

[0098] Figure 7 to Figure 9 It is the result of a hole expansion test performed on a metal plate made of steel grade C. Figure 7 to Figure 9 The vertical axis of is the same, indicating the ultimate strain of the stretched fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com