Visual measurement method of plate forming limit curve (FLC)

A forming limit curve and visual measurement technology, which is applied in the field of mechanical processing, can solve the problems of heavy workload for detection and calculation of limit strain, heavy workload for grid drawing, and low efficiency. It achieves short measurement cycle, wide application range, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and the measurement experiment of FLC of a certain steel material.

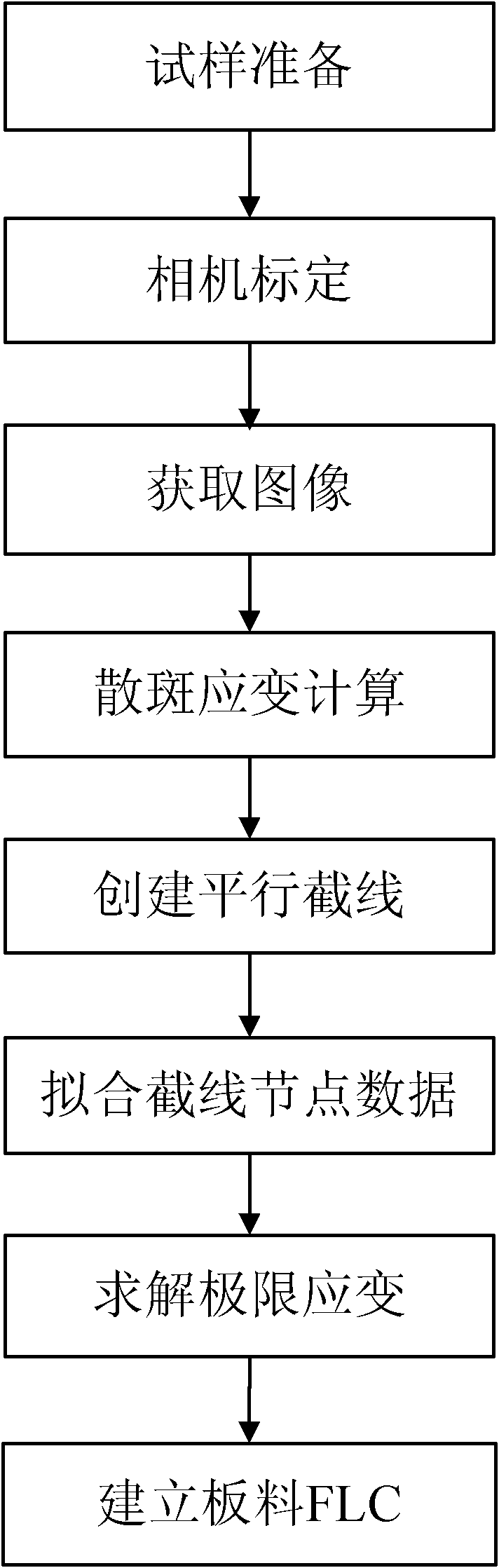

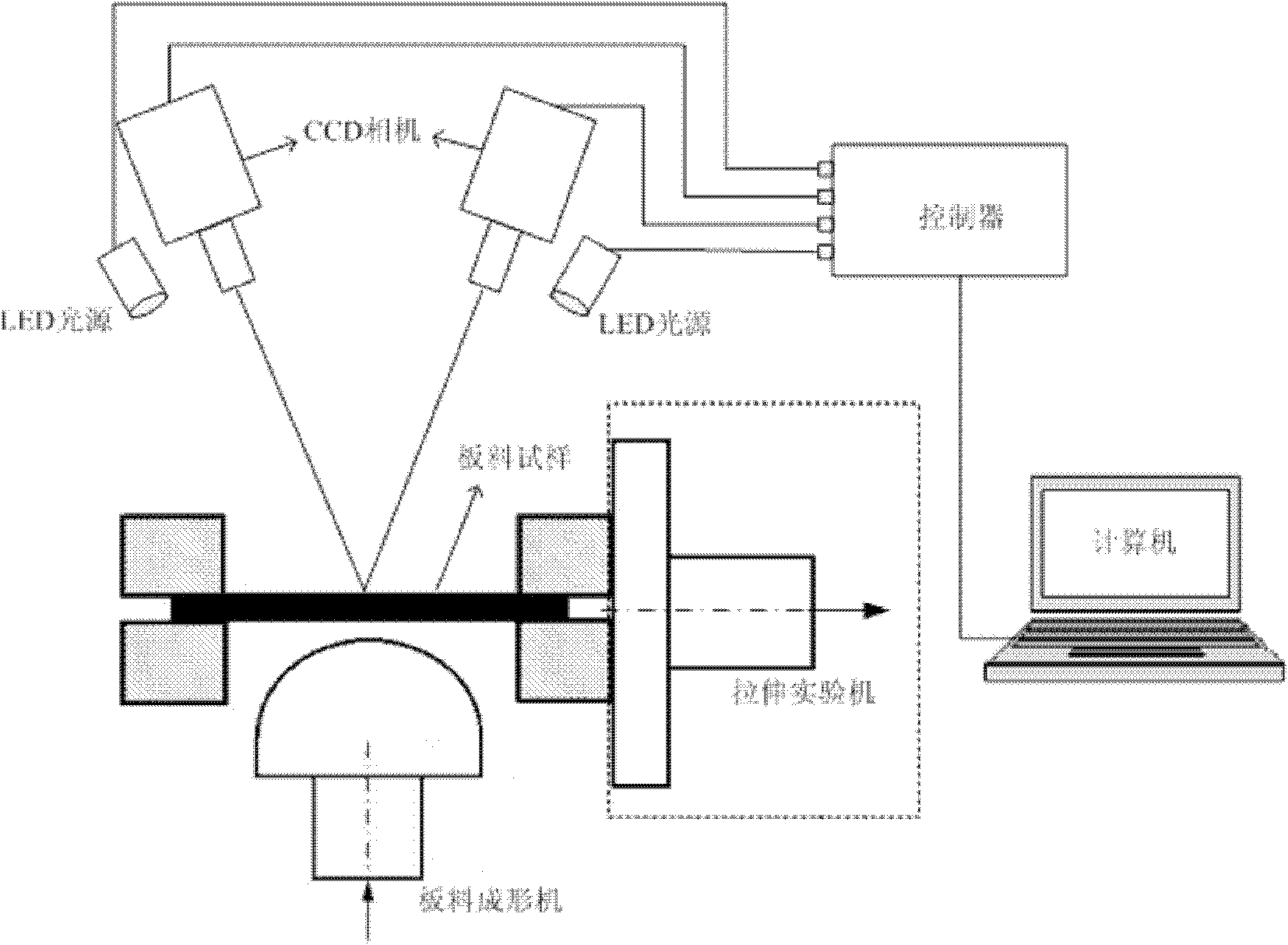

[0033] The present invention proposes a kind of sheet metal FLC measuring method, concrete operation steps are as follows figure 1 shown. The hardware structure of the experimental device used is as follows: figure 2 As shown, it is mainly composed of 2 CCD cameras, 2 LED lights, 1 sheet forming machine (or 1 material tensile testing machine), 1 computer, etc.

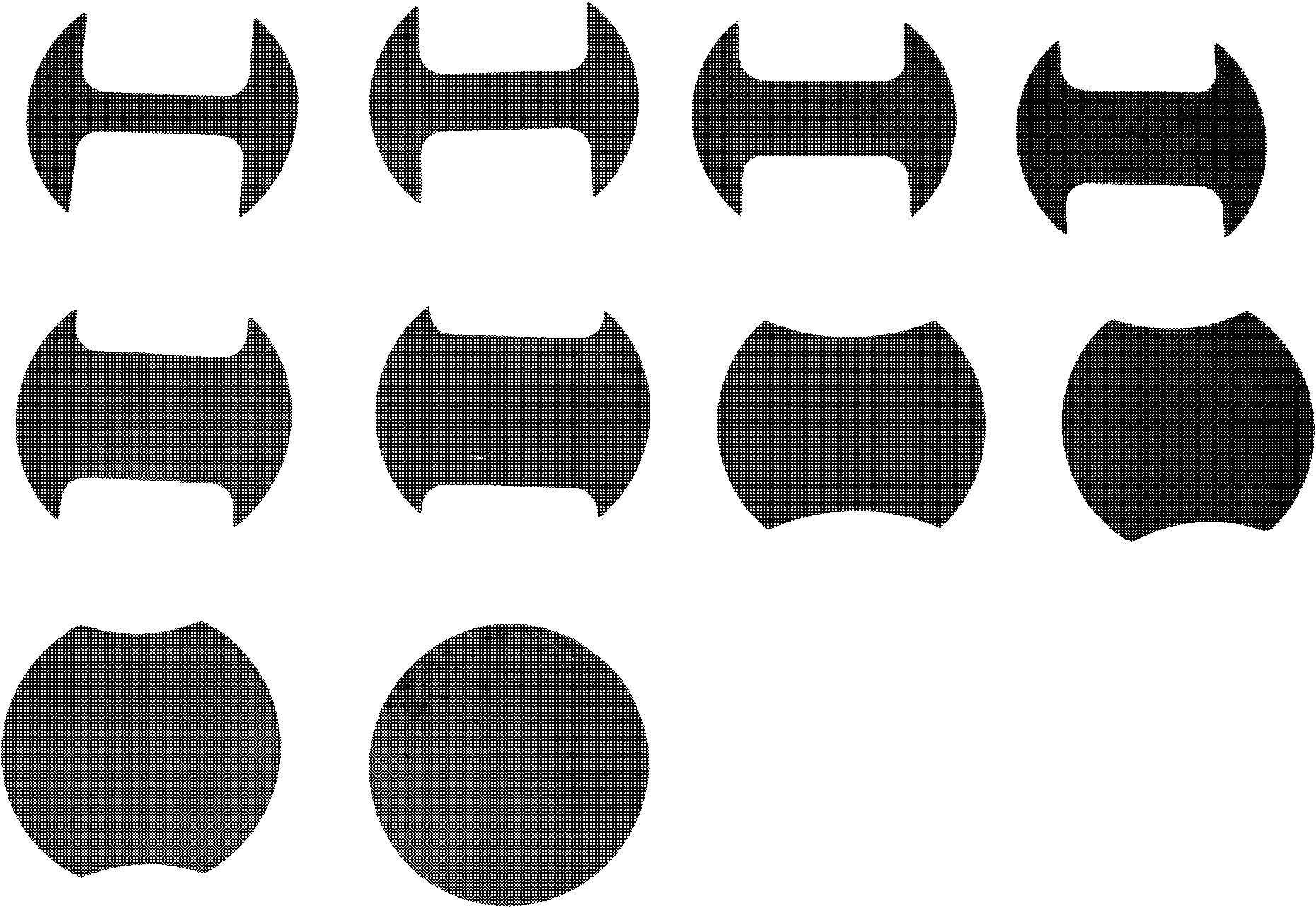

[0034] The first step is sample preparation, cutting the sheet blank into a sample that meets the standard size and geometric shape requirements (GBT24171.2), a group of experimental samples cut from a certain type of steel such as image 3 shown. Use artificial spray paint to make speckle patterns on the surface area of the sample to be measured (such as Figure 4 shown). Requirements for the preparation of sheet metal samples:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com