Solar power generation circulating cooling system and control method thereof

A circulating cooling system and control method technology, applied in the field of solar power generation, can solve the problems of high cost, low cooling efficiency, inconvenient use and installation, etc., and achieve the effects of easy assembly or disassembly, precise and perfect control, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

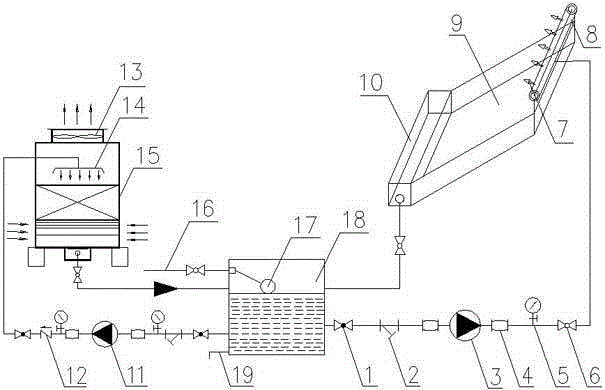

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

[0023] like figure 1 As shown, the solar power generation circulating cooling system includes: a water tank 18 and a circulating water pump 3, and cooling water is provided in the water tank 18; The function of gate valve 1 and Y-type filter 2 is to filter out impurities and particles in the water, and then through the circulating water pump 3, the soft connection 4 and then through the stop valve 6 to the nozzle 7 to generate spray water, between the circulating water pump 3 and the nozzle 7 There is also a pressure gauge 5 to observe the water flow pressure in real time. The spray water generated by the shower head 7 flows through the surface of the solar photovoltaic panel assembly 9 to take away heat, then flows into the water receiving tank 10 and returns to the water tank 18 again.

[0024] Wherein the solar photovoltaic panel assembly 9 is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com