Display base plate, manufacturing method thereof, display panel and display device

A technology for display substrates and display panels, applied in the fields of display substrates, manufacturing methods, display panels and display devices, capable of solving problems affecting the appearance of display devices, high cost of anti-peeping films, and easy damage, and reducing the viewing angle , reduce power consumption, improve the effect of display brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

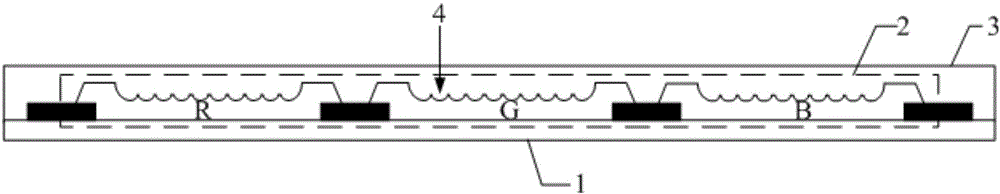

[0069] Example 1: If figure 1 The manufacturing method of the display substrate shown, such as Figure 4a-Figure 4e As shown, specifically, the following steps may be included:

[0070] 1. On the base substrate 1, form a pattern including a black matrix 5, such as Figure 4a shown; specifically, the formation process of the black matrix 5 graphics is similar to the formation process of the existing black matrix, and will not be repeated here;

[0071] 2. Coating green negative photoresist material on the base substrate 1 formed with black matrix 5 patterns to form a photoresist film 6, such as Figure 4b shown;

[0072] 3. Utilize mask plate 7 to carry out exposure treatment to photoresist film 6, as Figure 4c Shown; Wherein, the complete shading area of mask plate 7 corresponds to the area outside the green color filter (G) pattern to be formed, and the part light-transmitting area of mask plate 7 corresponds to the green color filter (G) to be formed ) the area whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com