Semi-automatic polarizer stripping device for liquid crystal display panel

A liquid crystal display panel and peeling device technology, which is applied in the directions of optics, nonlinear optics, lamination auxiliary operation, etc., can solve the problems of poor peeling effect and low work efficiency, and achieve the effect of not easy to break, high work efficiency and reliable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

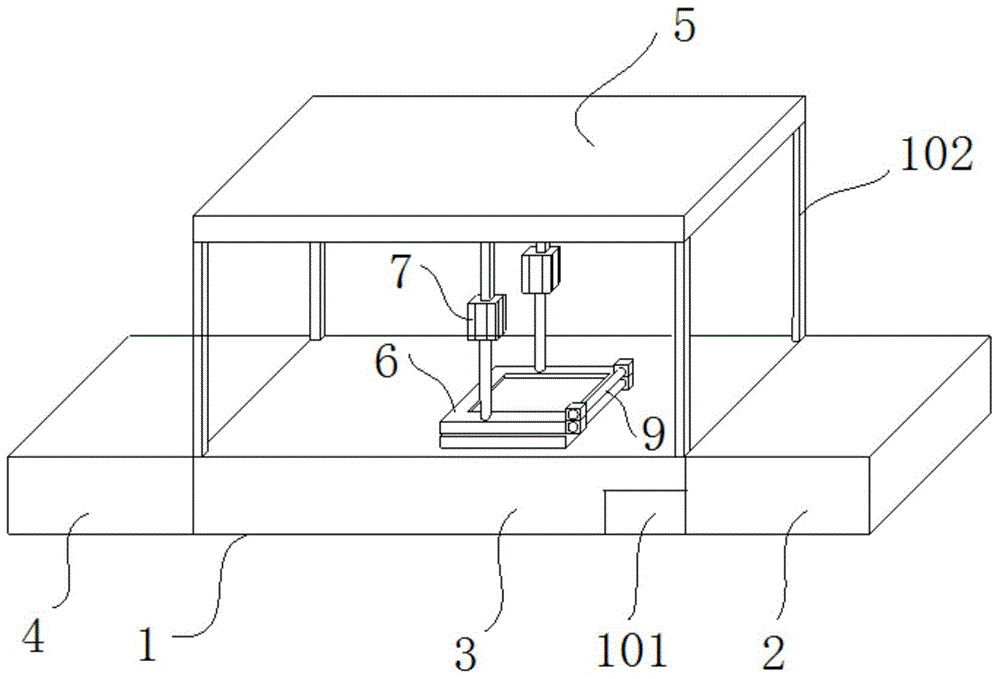

[0028] like figure 1 As shown, the semi-automatic polarizer peeling device for liquid crystal display panels of the present invention includes: a base 1, a first conveying device 2, a peeling platform 3, a second conveying device 4, a supporting plate 5, a heating plate 6 and a clamping device 9.

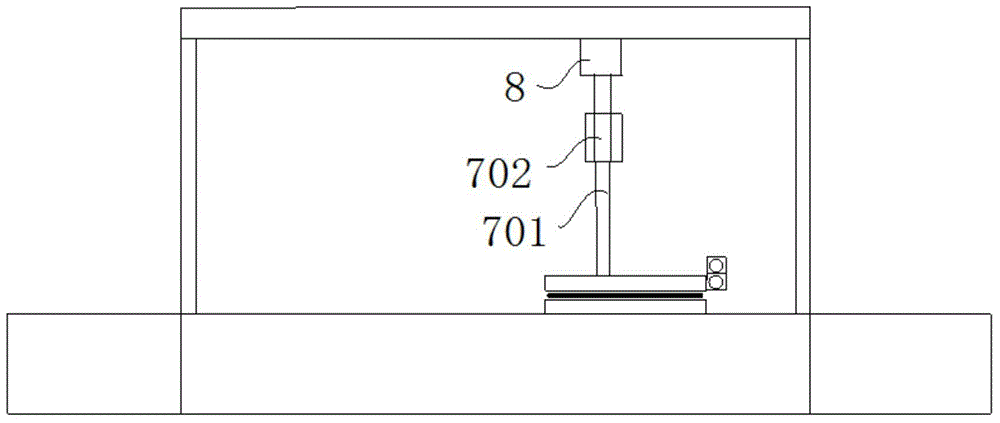

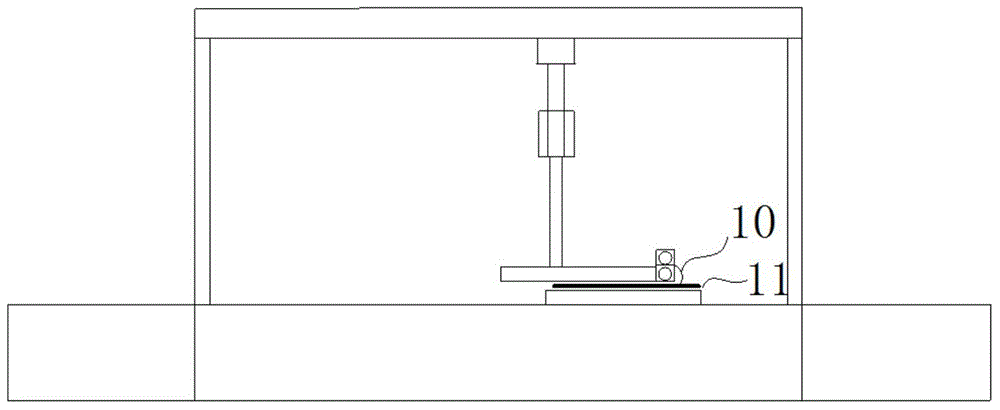

[0029] The base 1 is provided with a first conveying device 2 , a peeling platform 3 and a second conveying device 4 in sequence. The first conveying device 2 and the second conveying device 4 are long conveyor belts or roller tables, and the first conveying device 2 is used for conveying the liquid crystal display panel to be peeled off to the peeling platform 3, The second conveying device 4 is used for conveying the peeled liquid crystal display panel from the peeling platform 3 . The peeling platform 3 is a vacuum adsorption device, and the vacuum adsorption device is used for adsorbing the liquid crystal display panel 11 . The upper surface area of the vacuum adsorption dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com