Efficient cooling large-mode-area mid-infrared photonic crystal optical fiber and laser device thereof

A photonic crystal fiber, large mode field technology, applied in lasers, phonon exciters, laser components and other directions, can solve the problems of fiber collapse, low quantum efficiency, etc., to reduce the refractive index difference and reduce the equivalent refractive index , the effect of expanding the mode field diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

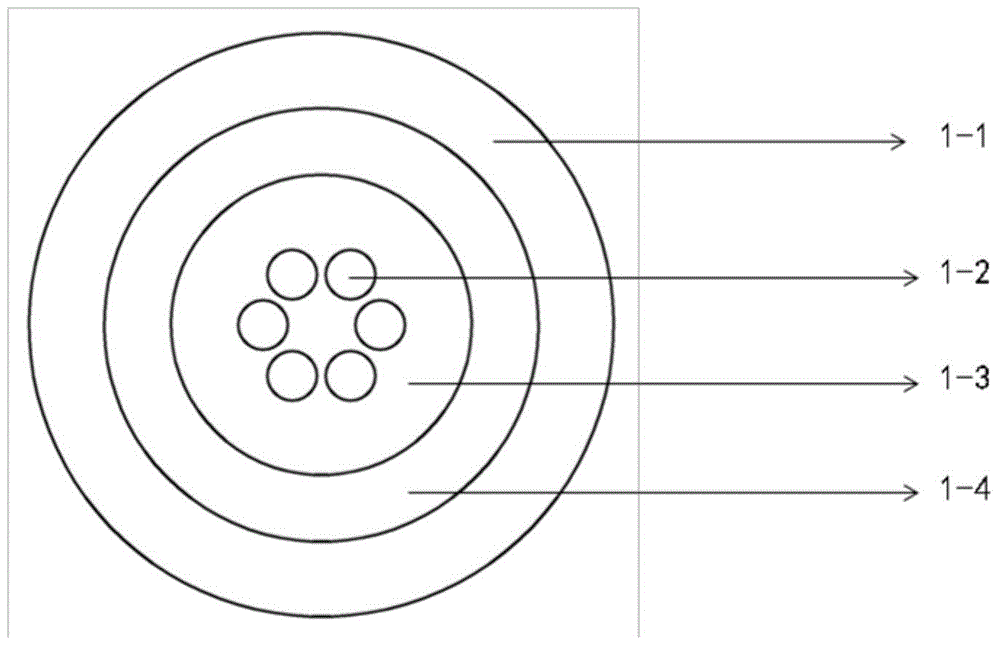

[0021] figure 1 It is a cross-sectional view of a large mode field area mid-infrared photonic crystal fiber. As shown in the figure, the outer cladding 1-1 of the optical fiber is fluororesin, the inner cladding 1-4 of the optical fiber is fluoride glass, and the core 1 -3 is made of highly erbium-doped fluoride glass, and the fiber core is provided with multiple air holes 1-2. The air holes have a diameter d and are separated by a pitch Λ. The air hole has dual functions. On the one hand, by adjusting the structure of the air hole, the equivalent refractive index of the core glass is reduced, the refractive index difference between the core and the inner cladding is reduced, and the mode field diameter of the optical fiber is expanded; On the one hand, a dry and clean inert gas flow can be passed through the air hole to realize the heat dissipation of the fiber core.

[0022] The working principle of increasing the mode field of photonic crystal fiber is as follows: the ref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com