Method for analyzing distribution of sulfur in methyl tert-butyl ether, sulfide qualitative analysis database, and use of database

A technology for qualitative analysis of methyl tert-butyl ether, applied in the field of analytical chemistry, can solve problems that have not yet been reported in the literature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

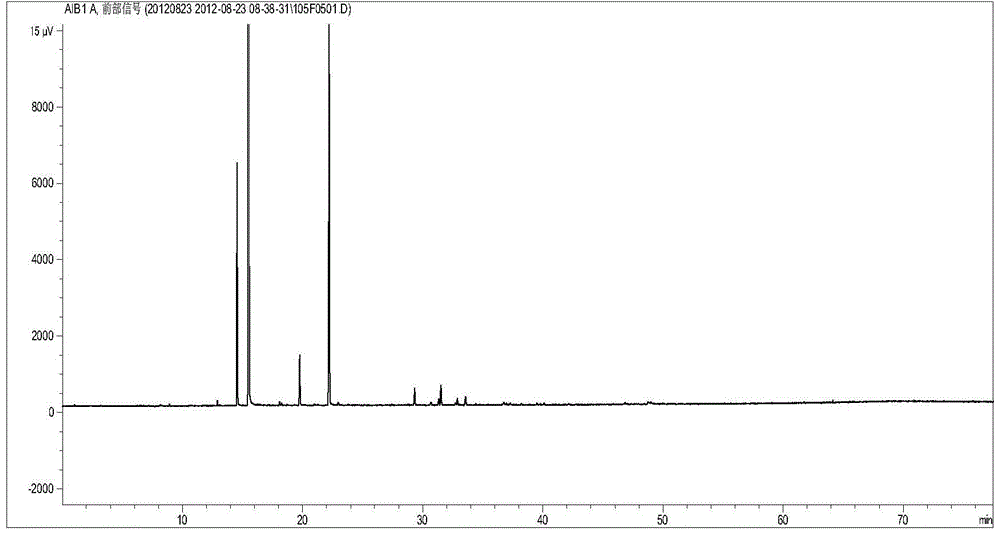

[0207] Sample to be tested: MTBE products at the production site of Jiujiang Petrochemical on October 10, 2012

[0208] Analysis conditions:

[0209] Chromatographic column: non-polar quartz capillary column, 50m×0.2mm×0.5μm

[0210] Carrier gas: high purity helium,

[0211] Head pressure: 150kPa,

[0212] Column flow: 0.6mL / min, constant sulfur analysis,

[0213] Injection port temperature: 230°C,

[0214] Injection volume: 1μL,

[0215] Split ratio: 200:1,

[0216] Column temperature: the initial temperature is 35°C, the first-stage temperature rise rate is 3°C / min, the first-stage final temperature is 90°C, the second-stage temperature rise rate is 20°C / min, the second-stage final temperature is 250°C, and kept for 10 minutes.

[0217] SCD detector pressure: 7Torr,

[0218] Burner temperature: 800°C,

[0219] Hydrogen: 40mL / min, Air: 60mL / min,

[0220] Background noise: 1.0mV.

[0221] Qualitative and quantitative analysis:

[0222] The methyl tert-butyl ether pr...

Embodiment 2

[0229] According to the MTBE product sulfur quantitative analysis condition of embodiment 1, adopting sulfur content is the diethyl disulfide external standard sample of 150mg / L to determine the quantitative response factor, regularly analyzed the production site MTBE product. See Table 15 for the sulfur distribution analysis report of MTBE products at the production site on August 20, 2012. Among them, the sulfide whose structure is not determined has a sulfur content of 0.63% of the total sulfur.

[0230] Table 15 2012.08.20 MTBE product sulfur distribution analysis report

[0231]

[0232]

Embodiment 3

[0234] According to the MTBE product sulfur quantitative analysis conditions of Example 1, the external standard sample of ethyl methyl sulfide with a sulfur content of 30 mg / L was used to determine the quantitative response factor, and the production site MTBE product was regularly analyzed. See Table 16 for the sulfur distribution analysis report of MTBE products at the production site on October 20, 2012. Among them, the sulfide whose structure is not determined has a sulfur content of 0.82% of the total sulfur.

[0235] Table 16 2012.10.20 MTBE product sulfur distribution analysis report

[0236]

[0237]

[0238] In a word, the method for qualitative / quantitative analysis of sulfur distribution in methyl tert-butyl ether products established by the present invention using gas chromatography / sulfur chemiluminescence detector can identify formazan at one time by relying on the sulfide qualitative analysis database described in the present invention Most of the sulfur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com