Waste disposal device realizing thermolysis, incineration and melting integration

A technology for processing equipment and waste, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve problems such as human living environment hazards, achieve outstanding environmental protection effects, stable operation, and increase temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further described in conjunction with the accompanying drawings and specific embodiments.

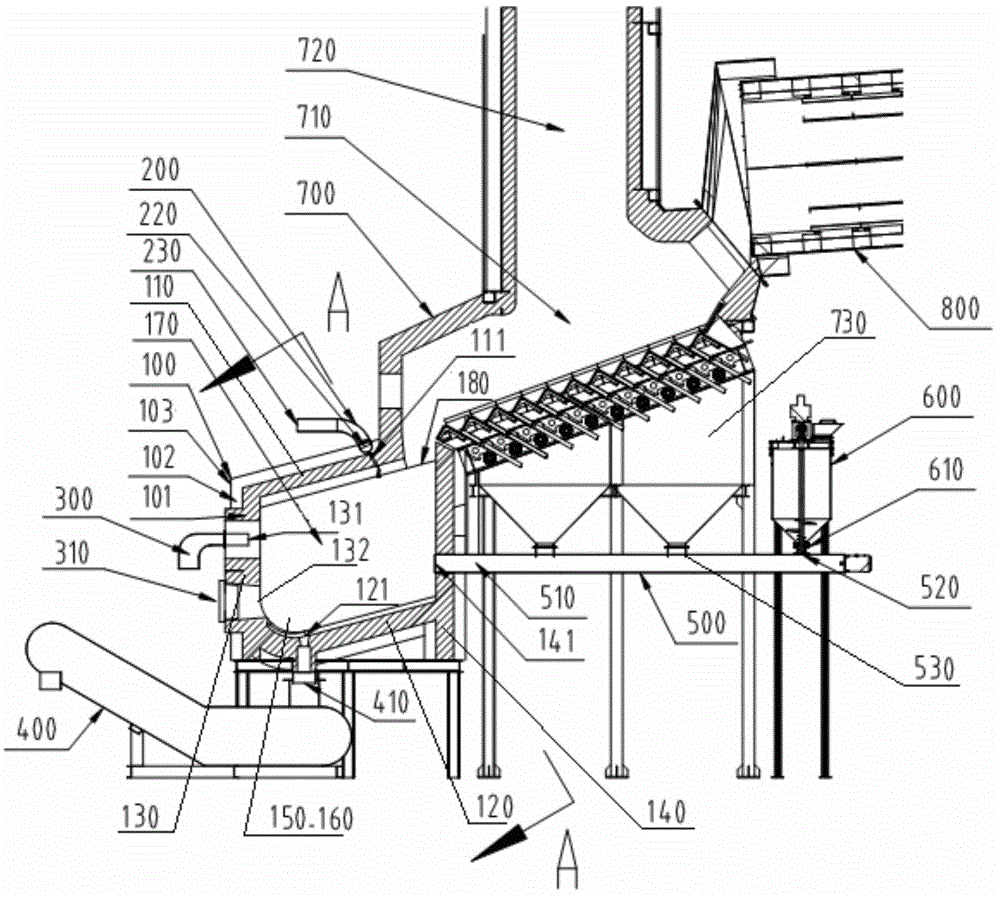

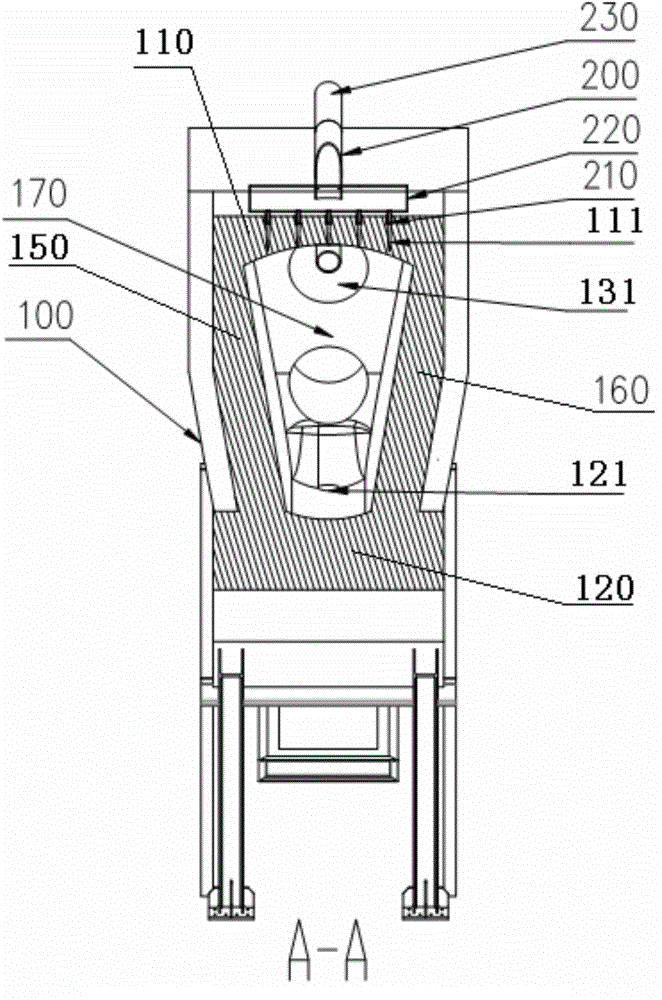

[0027] see figure 1 and figure 2 , the pyrolysis, incineration and melting integrated waste treatment device shown in the figure includes an incinerator 700, which has a first combustion chamber 710 and a second combustion chamber 720 communicating with each other, and the second combustion chamber 720 is located at Above the first combustion chamber 710; the incinerator 700 also has a plurality of ash drop ports 730 in the primary air chamber.

[0028] The pyrolysis, incineration and melting integrated waste treatment device of this specific embodiment also includes a furnace roof 110 that is vertically high at the front and low at the rear and horizontally upwardly curved, a groove-shaped furnace bottom 120 that is vertically high at the front and low at the rear, and The furnace wall 130, the front furnace wall 140, the left and right furnace walls ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com