Uplift pile construction method without rock blasting

A construction method and a technology for uplift-resistant piles, which are applied in drilling equipment and methods, sheet pile walls, and earthwork drilling and mining, etc., can solve problems such as inability to meet or fail to meet the geological conditions of the whole rock, and achieve high speed and good energy-saving effect. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The invention will be further described below in conjunction with the accompanying drawings.

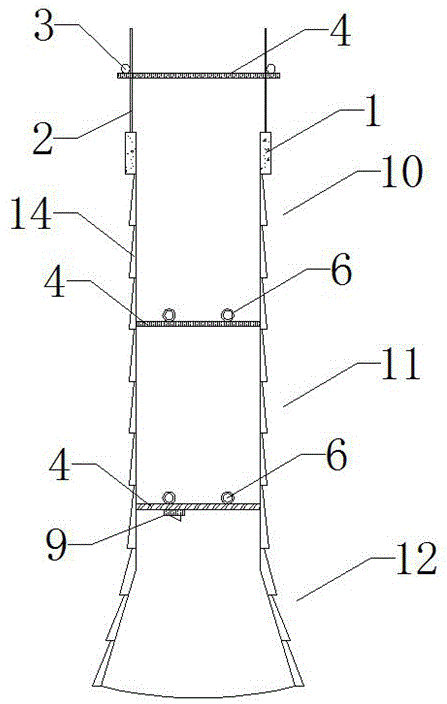

[0041] like figure 1 As shown, the construction of the uplift pile of the present invention is carried out in three sections from the top to the bottom of the pile, one is the construction of the orifice section 10, the other is the construction of the standard section 11, and the third is the construction of the expansion section 12.

[0042] Orifice section construction:

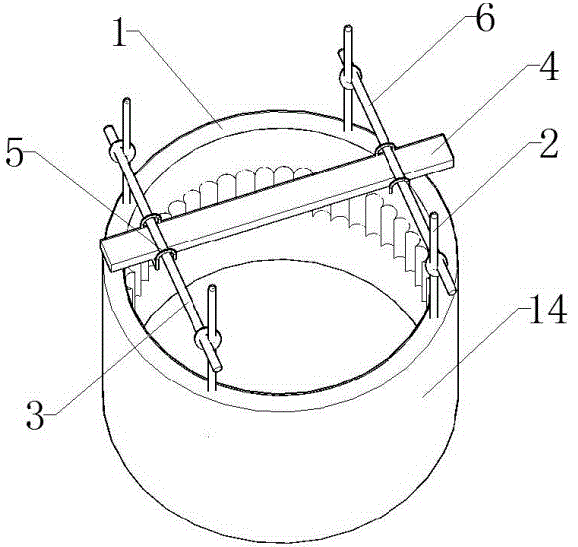

[0043] like figure 2 As shown, before the construction of the orifice section 10, after the stake position is measured and staked out, the concrete of the locking ring beam 1 is made centering on the center point of the pile, and four holes are buried at equal intervals on the locking ring beam 1 made of concrete The reaction force frame column 2 of the mouth section, the height of the reaction force frame column 2 matches the parameters of the rock core-pulling fuselage; after the concrete strength of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com