Prestress jacquard guide needle

A yarn guide, prestressing technology, applied in knitting, warp knitting, textile and papermaking, etc., can solve the problems of offset displacement and small output force, achieve large offset and output force, and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

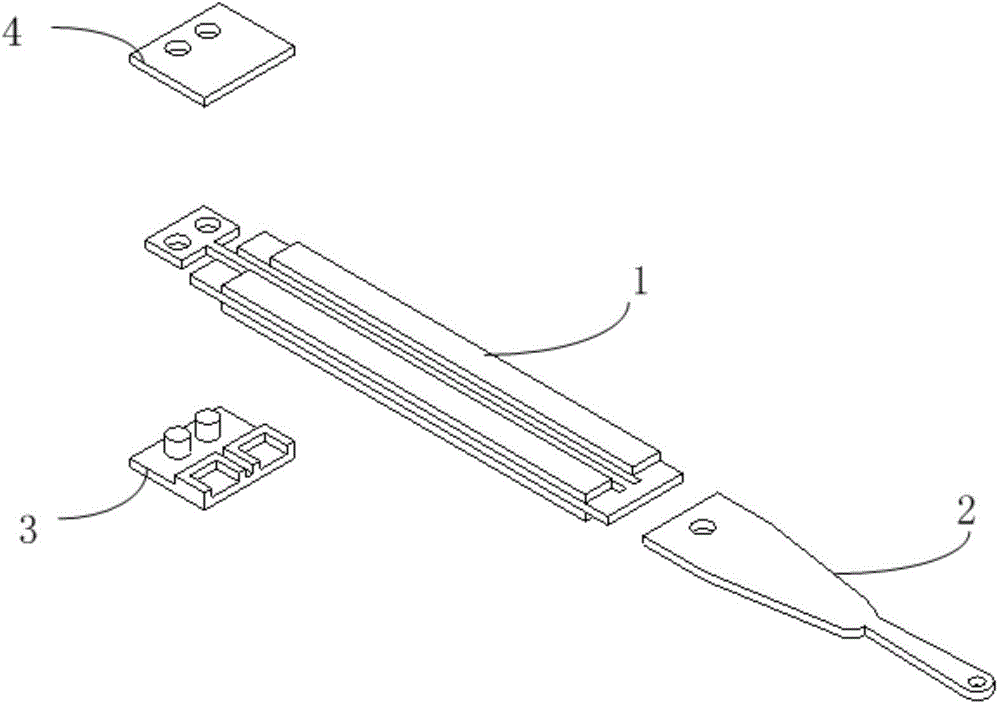

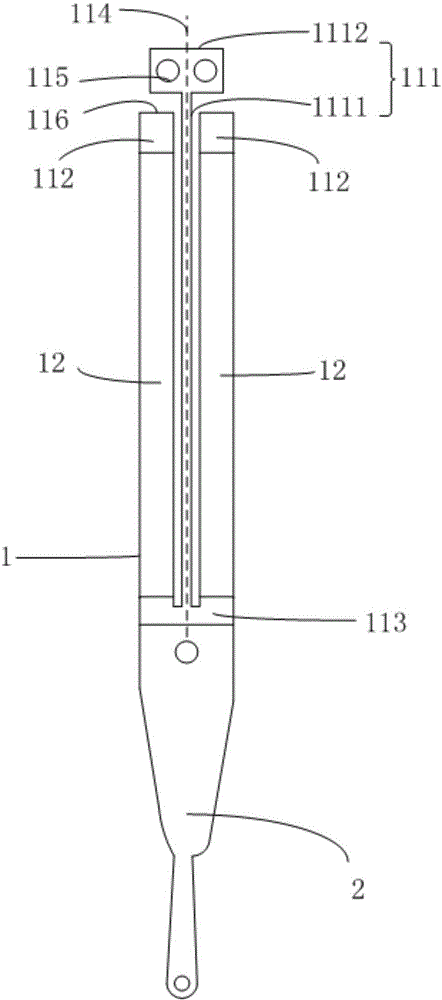

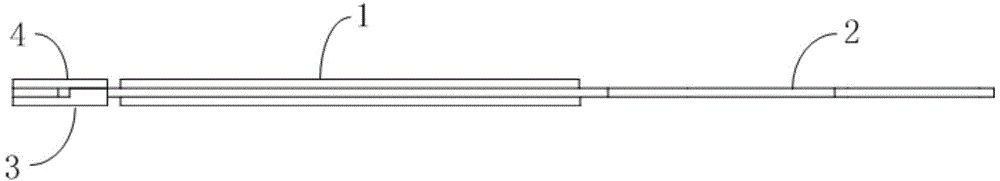

[0012] refer to figure 1 , figure 2 , image 3 and Figure 4 , a prestressed jacquard guide needle, comprising a piezoelectric vibrator 1, a guide needle 2, a lower positioning block 3 and an upper positioning block 4, characterized in that:

[0013] The piezoelectric vibrator 1 includes an elastic substrate 11 and four pieces of piezoelectric ceramics 12; the elastic substrate 11 is a sheet structure, including a middle cantilever 111, two side cantilever 112 and a cantilever connection area 113; the middle cantilever 111 includes a middle cantilever An elongated area 1111 and an intermediate cantilever fixing area 1112, one end of the intermediate cantilever elongating area 1111 is arranged on one side of the cantilever connection area 113, and the middle cantilever fixing area is arranged at the other end of the intermediate cantilever elongating area 1111. area 1112, two middle cantilever positioning holes 115 that are symmetrical about the symmetry axis 114 of the ela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com