Novel warp knitting machine guide bar device

A warp knitting machine and bar technology, which is applied in the field of new warp knitting machine bar devices, can solve the problems of affecting the moving speed, low efficiency, and large friction area, so as to improve the moving speed and service life, and reduce maintenance costs , the effect of small contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with accompanying drawings and specific preferred embodiments, so that the advantages and features of the present invention can be more easily understood by those skilled in the art. range is limited.

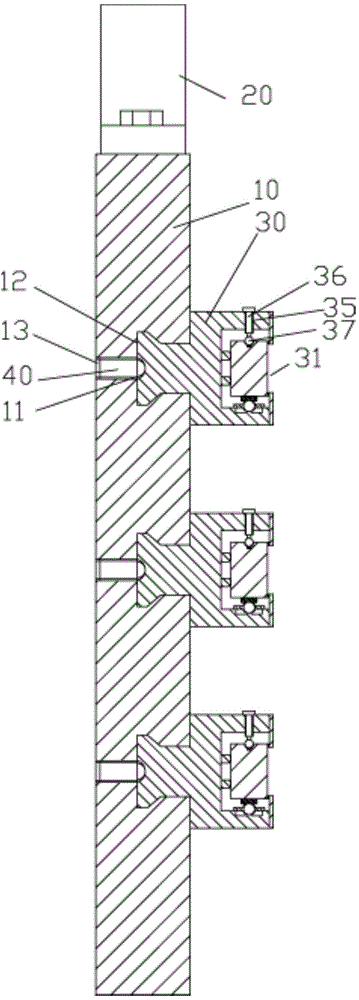

[0021] Examples, see e.g. Figure 1 to Figure 4 As shown, a novel warp knitting machine bar device includes a bar plate 10 and a bar bar 100, the top of the bar plate 10 is fixed with a support 20, and the side wall of the bar plate 10 has a plurality of transverse Slot 12, a plurality of comb strip support blocks 30 are inserted and sleeved in the slot 12, the back side of the comb plate 10 has a plurality of screw holes 13, the screw holes 13 communicate with the slot 12, and the ball plunger 40 is screwed on In the screw hole 13, the steel ball of the ball plunger 40 stretches into the slot 12 and is inserted in the concave hole 11 that is provided on the back wall surface of the bar bar support b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com