Method for cultivating microalgae by using CO2

A CO2 and microalgae technology, applied in the direction of unicellular algae, can solve the problems of low utilization rate of CO2, decrease of biomass yield of microalgae, toxicity of microalgae cells, etc., to achieve high utilization rate of CO2 and improve biomass production. rate, no toxic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A columnar glass photobioreactor (height 50cm, inner diameter 6cm) is used indoors to cultivate microalgae, and aeration stones commonly used in this field (aperture 30-60μm) are used to provide a light intensity of 100μmol·m from 8 fluorescent tubes. -2 ·s -1 The 12h:12h (light:dark) of the light. The algal species is Scenedesmus dimorphus, which comes from the freshwater algae species bank of the Institute of Hydrobiology, Chinese Academy of Sciences, number 496. Scenedesmus dimorphus was cultured with BG11 as the medium, and the culture volume was 1L. When preparing the medium, Tris was added to a final concentration of 2 mmol / L, the medium was sterilized at 121°C and 0.1 MPa for 20 minutes, and microalgae were added after cooling. Use an air conditioner to control the room temperature at 25°C, and continuously feed air to drive the culture medium to mix for 24 hours. The air flow rate is 180mL / min. During the period of 12 hours of illumination, pure CO is fed ever...

Embodiment 2

[0049] Others are the same as in Example 1, except that Tris is added to the medium to a final concentration of 4mmol / L.

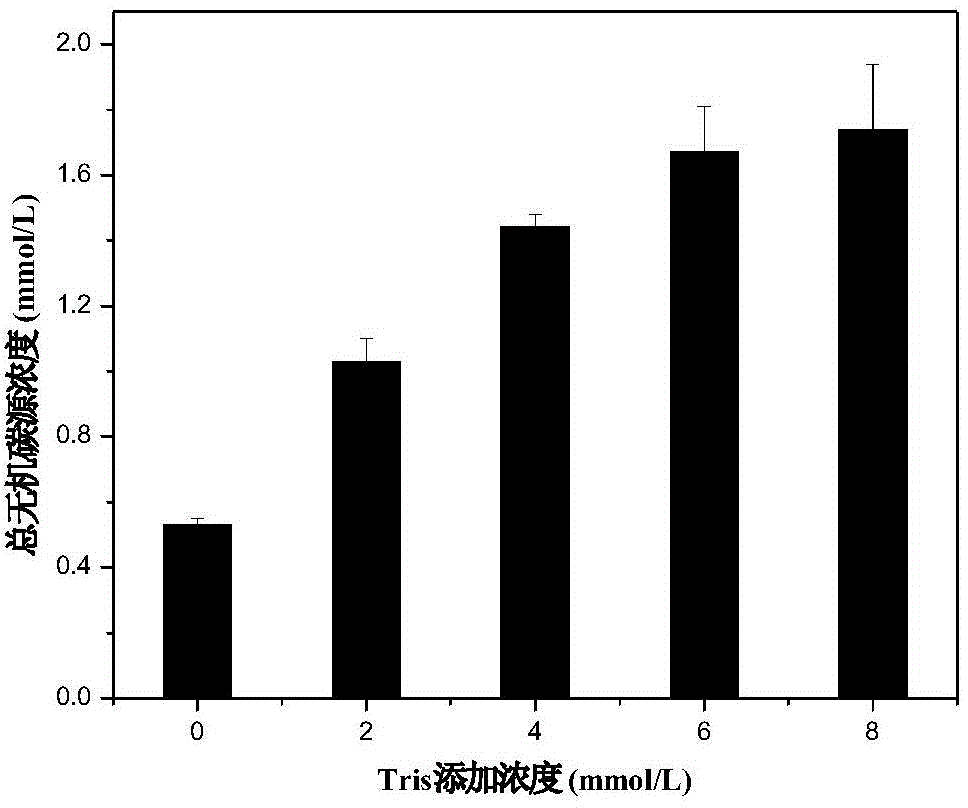

[0050] Adding Tris with a final concentration of 4mmol / L in the culture medium, the average total inorganic carbon source concentration in the culture medium during the culture was 1.44mmol / L; while using the same reactor and the same culture conditions to cultivate the same microalgae, only Without adding Tris, the average total inorganic carbon source concentration of the culture medium was 0.53mmol / L, such as figure 1 shown.

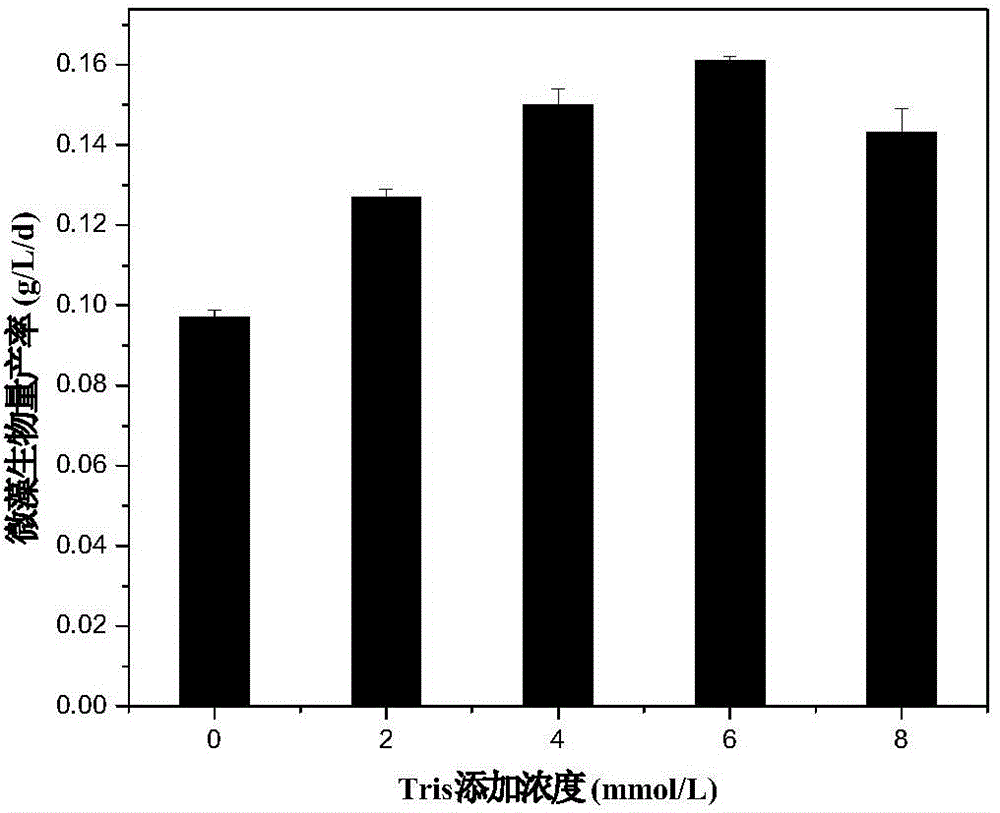

[0051] Adding Tris with a final concentration of 4mmol / L in the medium, the average biomass production rate of batch culture for 8 days was 0.15g / L / d; while using the same reactor and the same culture conditions to cultivate the same microalgae, Just without adding Tris, the average biomass yield obtained by batch culture for 8 days was 0.097g / L / d, such as figure 2 shown.

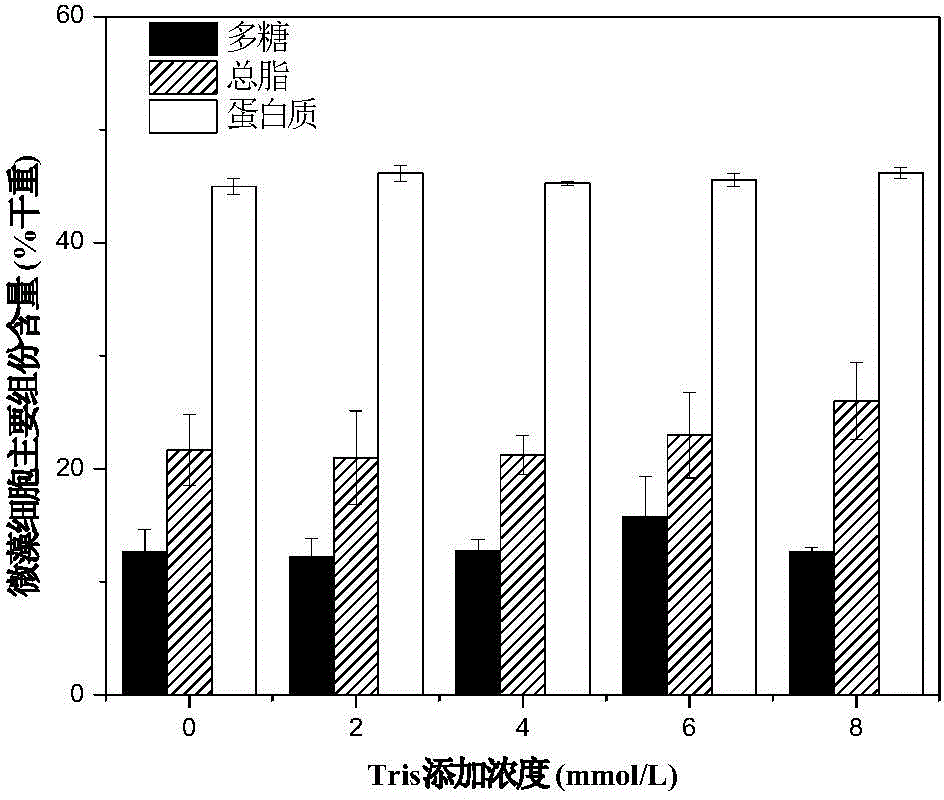

[0052]Adding Tris with a final concentration of 4mmol...

Embodiment 3

[0059] Others are the same as in Example 1, except that Tris is added to the medium to a final concentration of 6 mmol / L.

[0060] Adding Tris with a final concentration of 6mmol / L in the culture medium, the average total inorganic carbon source concentration in the culture medium during the culture was 1.67mmol / L; while using the same reactor and the same culture conditions to cultivate the same microalgae, only Without adding Tris, the average total inorganic carbon source concentration of the culture medium was 0.53mmol / L, such as figure 1 shown.

[0061] Adding Tris with a final concentration of 6mmol / L in the medium, the average biomass production rate of batch culture for 8 days was 0.16g / L / d; while using the same reactor and the same culture conditions to cultivate the same microalgae, Just without adding Tris, the average biomass yield obtained by batch culture for 8 days was 0.097g / L / d, such as figure 2 shown.

[0062] Adding Tris with a final concentration of 6mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com