Multi-flavor kick type low-alcohol wine prepared from phyllanthus emblica L and preparation method of low-alcohol wine

A technology of emblica and low-alcohol wine, which is applied in the field of wine manufacturing, can solve the problems of heavy sour taste of wine, lower quality of raw materials, easy to turn black and moldy, etc., and achieve spicy and refreshing taste, long-lasting killing power and golden color. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Hot

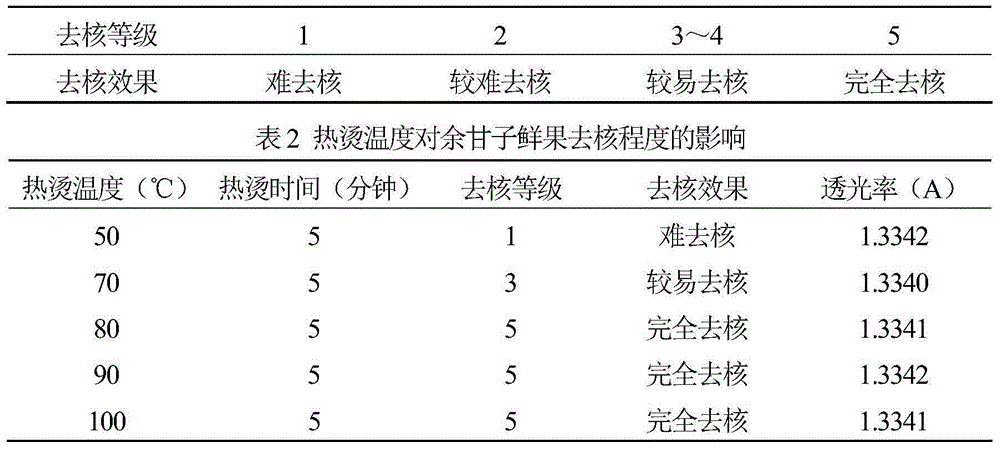

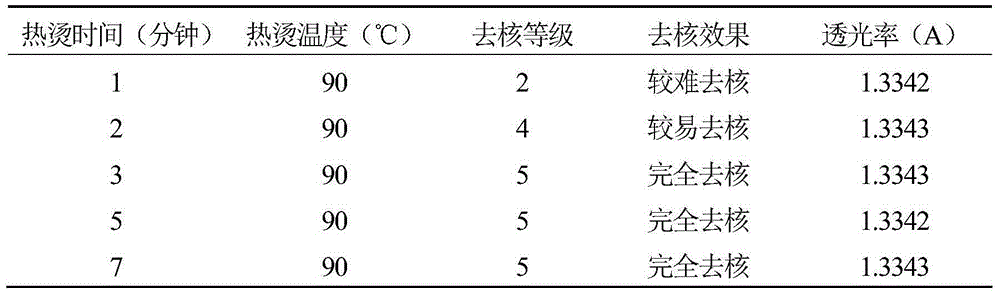

[0035] Select fresh emblica fruits free from diseases, insect pests and rot, clean the soil and sundries on the surface of 20 kg of fresh emblica fruits with tap water, then put them into hot water at 90°C, and scald them for 3 minutes.

[0036] 2. Drying

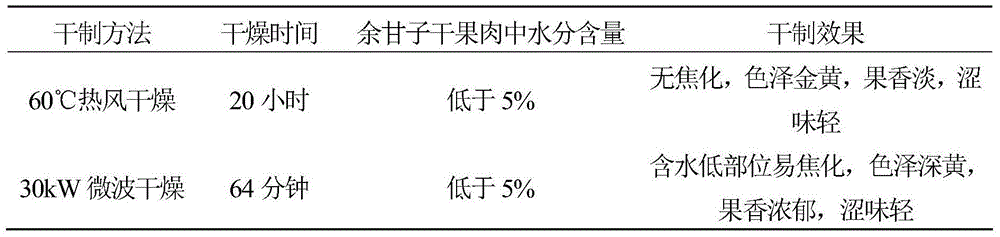

[0037] Use a pitting machine to remove the pits from the scalded emblica fruit, and the obtained emblica pulp is dried to a moisture content of 18% with a microwave power of 30kW, and then transferred to a blast drying box at 60°C Dried under hot air for 6 hours to obtain dry pulp of emblica with a moisture content lower than 5%.

[0038] 3. Enzyme hydrolysis

[0039] Utilize a 60-mesh hammer mill to pulverize the dried emblica fruit pulp, add pure water 8 times its quality to the obtained emblica fruit powder, stir evenly, then add pure water and 0.0156‰ of the total mass of emblica fruit powder, and the activity is 20000U / g of pectinase, after enzymatic hydrolysis at 56°C for 5 hours, centrifuge and re...

Embodiment 2

[0051] 1. Hot

[0052] Select fresh emblica fruits free from diseases, insect pests and rot, clean the soil and sundries on the surface of 20 kg of fresh emblica fruits with tap water, then put them in hot water at 80°C, and scald them for 5 minutes.

[0053] 2. Drying

[0054] Use a pitting machine to remove the pits from the scalded emblica fruit, and dry the obtained emblica pulp with a microwave power of 50kW until the moisture content is 15%, and then transfer it to a blast drying box at 60°C Dried under hot air for 5 hours to obtain dry pulp of emblica with a moisture content lower than 5%.

[0055] 3. Enzyme hydrolysis

[0056] Use a 60-mesh hammer mill to pulverize the dried emblica pulp, add 5 times the quality of pure water to the obtained emblica fruit powder, stir evenly, and then add pure water and 0.010‰ of the total mass of emblica fruit powder. The activity is 20000U / g of pectinase, after enzymatic hydrolysis at 49°C for 5 hours, centrifuge and remove slag ...

Embodiment 3

[0068] 1. Hot

[0069] Select fresh emblica fruit free of diseases, insect pests and rot, clean the soil and sundries on the surface of 20 kg of fresh emblica fruit with tap water, then put it into hot water at 100°C, and scald it for 2 minutes.

[0070] 2. Drying

[0071] Use a pitting machine to remove the pits from the scalded emblica fruit, and the obtained emblica pulp is dried to a moisture content of 25% with a microwave power of 20kW, and then transferred to a blast drying box at 60°C Dried under hot air for 8 hours to obtain dry pulp of emblica with a moisture content lower than 5%.

[0072] 3. Enzyme hydrolysis

[0073] Utilize a 60-mesh hammer mill to pulverize the dried emblica fruit pulp, add pure water 10 times its mass to the obtained emblica fruit powder, stir evenly, then add pure water and 0.020‰ of the total mass of emblica fruit powder, and the activity is 20000U / g of pectinase, after enzymatic hydrolysis at 56°C for 4 hours, centrifuge and remove slag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com