Graphene/thermoplastic polyurethane composite and preparation method thereof

A thermoplastic polyurethane and composite material technology, which is applied in the field of polymer composite film preparation, can solve problems such as danger and adverse effects on polymer physical properties, and achieve the effects of preventing agglomeration, scientific and reasonable preparation methods, and simple procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Add 150mg of GO to 20ml of DMF solution to form a stable graphite oxide DMF dispersion, and ultrasonically disperse it at 100W for 2h. After it is stable, pour it into the TPU solution pre-swelled in DMF, and stir at room temperature for 2~5h. Ultrasonic disperse at 100W for 1~2h to remove the air in the pasty liquid and let it stand for 1~2h;

[0031] 2) Film coating: place the glass plate with a clean surface on the film coating machine to coat the film, control the film thickness to 0.06~0.08mm, and obtain the graphene oxide / thermoplastic polyurethane composite material after the solvent is fully volatilized.

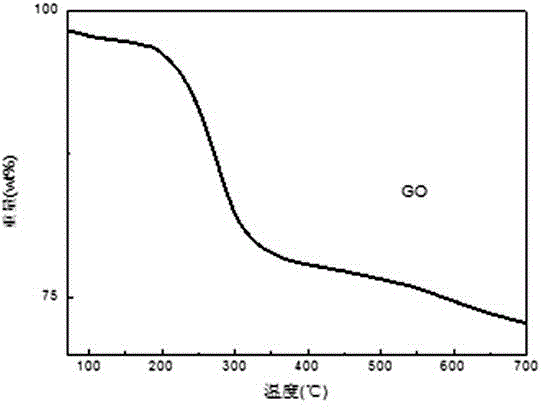

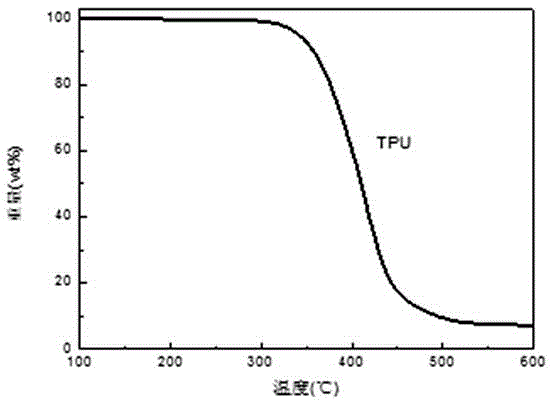

[0032] 3) Preparation of in-situ thermally reduced graphene / polyurethane composite material: the obtained graphene oxide / thermoplastic polyurethane composite material was baked in an oven at 200 °C for 2 h, and the composite material changed from dark brown to gray-black, and the original Thermally reduced graphene / polyurethane composite (marked as 1#TPU). ...

Embodiment 2

[0034] 1) Add 300mg of GO to 20ml of DMF solution to form a stable graphite oxide DMF dispersion, and disperse it ultrasonically at 100W for 2h. After it is stable, pour it into the TPU solution pre-swelled in DMF, and stir at room temperature for 2~5h. Ultrasonic disperse at 100W for 1~2h to remove the air in the pasty liquid and let it stand for 1~2h;

[0035] 2) Film coating: place the glass plate with a clean surface on the film coating machine to coat the film, control the film thickness to 0.06~0.08mm, and obtain the graphene oxide / thermoplastic polyurethane composite material after the solvent is fully volatilized.

[0036] 3) Preparation of in-situ thermally reduced graphene / polyurethane composite material: the obtained graphene oxide / thermoplastic polyurethane composite material was baked in an oven at 200 °C for 2 h, and the composite material changed from dark brown to gray-black, and the original Thermally reduced graphene / polyurethane composite (marked as 2#TPU). ...

Embodiment 3

[0038] 1) Add 450mg of GO to 20ml of DMF solution to form a stable graphite oxide DMF dispersion, and ultrasonically disperse it at 100W for 2h. After it is stable, pour into the TPU solution pre-swelled in DMF, and stir at room temperature for 2~5h. Ultrasonic disperse at 100W for 1~2h to remove the air in the pasty liquid and let it stand for 1~2h;

[0039] 2) Film coating: place the glass plate with a clean surface on the film coating machine to coat the film, control the film thickness to 0.06~0.08mm, and obtain the graphene oxide / thermoplastic polyurethane composite material after the solvent is fully volatilized.

[0040] 3) Preparation of in-situ thermally reduced graphene / polyurethane composite material: the obtained graphene oxide / thermoplastic polyurethane composite material was baked in an oven at 200 °C for 2 h, and the composite material changed from dark brown to gray-black, and the original Thermally reduced graphene / polyurethane composite (marked as 3#TPU).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com